Sheets of Honeycomb Aluminum Louver Gutter Roof Aluminium Composite Panel 1100 3003

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Gutter Roof Aluminium Composite Panel 1100 3003

Alloy: 1050, 1060, 1100, 3003, 3004, 3005, 3105, 5005, 5052, 5083, 5754

2) Temper: Various status

3) Thickness: 0.3-150mm

4) Width: 300-1950mm

5) Length: Under9500mm/ Coil

6) Weight: 2.5-5.0 tons per coil

7) Dimensions and weight can be produced according to clients' specifications.

8) Inner Diameter: 505mm, 605mm

9) Packing: Export standard, wooden pallet.

10) Delivery time: 20 days

11) Minimum order quantity: 5 tons per size.

12) The term of payment: T/T, irrevocable L/C at sight.

13) Surface: Bright

14)Origin: China

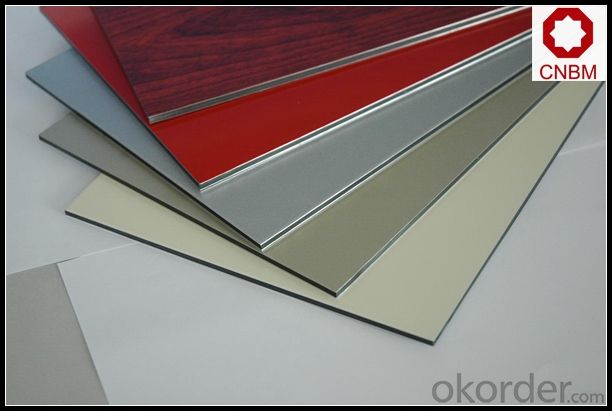

2. Application of Gutter Roof Aluminium Composite Panel 1100 3003

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Gutter Roof Aluminium Composite Panel 1100 3003

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

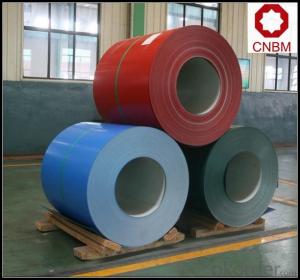

5. Image of Gutter Roof Aluminium Composite Panel 1100 3003

6. Package and shipping of Gutter Roof Aluminium Composite Panel 1100 3003

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What is made when Aluminium and Hydrochloric Acid reacts? It makes a dense white smoke with a metallic odour in the gas. Could it be dissolved amounts of Aluminium Chloride or small amounts of unreacted Aluminium in the gas? Or could be that the Chlorine (in equilibrium with HCl and HClO) made chlorates and perchlorates of aluminium that give off odours?Don't tell me the gas isn't supposed to have an odour. I know what diatomic Hydrogen smells like. Nothing. That's the way it should be. But unfortunately, that's not the way it is.

- When aluminum reacts with hydrochloric acid heat is produced as well as aluminum chloride. This heat is warming up the HCl, which you should remember is a gas dissolved in water, a little of which evolves from the water. You're smelling HCl gas. There shouldn't be any dense white smoke, unless you've got an open container of ammonia nearby. In that case the smoke is particulate ammonium chloride, produced by the reaction in the air of HCl and NH3.

- Q: Can aluminum sheets be used as heat shields?

- Yes, aluminum sheets can be used as heat shields. Aluminum has high thermal conductivity, which means it can effectively absorb and distribute heat, making it an excellent material for heat protection. It is commonly used in various applications such as automotive, aerospace, and industrial settings to shield sensitive components from high temperatures.

- Q: What is the thickness of an aluminum sheet?

- The thickness of an aluminum sheet can vary depending on the specific application and requirements. Aluminum sheets are available in a wide range of thicknesses, typically ranging from 0.006 inches (0.15mm) to 0.25 inches (6.35mm) or even thicker. The thickness is usually measured in gauge, with higher gauge numbers indicating thinner sheets. It is important to consider the intended use and desired properties, such as strength, flexibility, or weight, when selecting the appropriate thickness for an aluminum sheet.

- Q: As for graphite and aluminum sheet, which one has a better thermal conductivity?

- aluminum sheet

- Q: Can aluminum sheets be used for architectural facades?

- Yes, aluminum sheets can be used for architectural facades. Aluminum is a versatile material that offers several advantages for facade applications. It is lightweight, durable, and corrosion-resistant, making it suitable for various weather conditions. Aluminum sheets can be easily fabricated and installed, offering flexibility in design and allowing for intricate and complex facades. Additionally, aluminum can be finished in a variety of ways, including powder coating, anodizing, or painting, to enhance its appearance and provide the desired aesthetic appeal. Overall, the use of aluminum sheets for architectural facades provides architects and designers with a wide range of options to create visually appealing and long-lasting building exteriors.

- Q: I want to make a part using molten aluminum with a hole through the middle and would like to use a steel rod to do this. Would the bar stick to the aluminum when it cools and not be able to be removed? If so is there so type of coating I can use so it can be removed?

- Unless the surface was specially prepared the aluminum won't bond to the steel. To be sure it doesn't, simply 'smoke ' the steel with a candle etc. (thin layer of carbon black), to ensure no bonding. Your problem will come from the different co-efficients of expansion. The aluminum will shrink more than the steel in cooling and will grab that rod very tightly. Your hole, ( therefore your rod), will have to have a considerable taper if you ever hope to drive that rod out of the casting. Caution- You are aware that most aluminum alloys will burn in air at pouring temperatures aren't you?

- Q: What are the typical thicknesses of aluminum sheets?

- The typical thicknesses of aluminum sheets vary depending on their intended use, but they usually range from 0.006 to 0.25 inches.

- Q: Are 101 aluminum sheets suitable for high-temperature applications?

- No, 101 aluminum sheets are not suitable for high-temperature applications. 101 aluminum is a pure aluminum alloy with excellent corrosion resistance and good formability, but it has a low melting point of 660 degrees Celsius (1220 degrees Fahrenheit). High-temperature applications typically require materials with higher melting points and better heat resistance, such as stainless steel or high-temperature alloys. Using 101 aluminum sheets in high-temperature environments could result in deformation, melting, or failure of the material, which could compromise the integrity and safety of the application.

- Q: What are the different methods of surface cleaning aluminum sheets?

- Depending on the amount of dirt or contamination, there are various ways to clean aluminum sheets. The following methods are commonly employed: 1. Mechanical Cleaning: This method entails physically scrubbing the aluminum sheet using brushes, abrasive pads, or sandpaper. It effectively removes light dirt, grease, or oxidation. However, caution must be exercised to prevent scratching or damaging the surface. 2. Chemical Cleaning: To eliminate dirt, stains, or oxidation, specific cleaning agents or solutions are employed. Alkaline cleaners, acidic cleaners, and solvents are frequently used. It is crucial to adhere to the manufacturer's instructions and take necessary safety precautions when handling chemicals. 3. Pressure Washing: High-pressure water jets are used to eliminate dirt, grime, and other contaminants from the aluminum sheet's surface. This method is quick and efficient, especially for large or heavily soiled surfaces. However, care should be taken to avoid excessive pressure that could dent or damage the aluminum. 4. Electrolytic Cleaning: An electrolyte solution and an electric current are utilized in this method to remove corrosion, oxidation, or tarnish from the aluminum sheet. The sheet is submerged in the electrolyte bath, and the electric current helps dissolve the contaminants. This method is particularly effective for heavily oxidized or tarnished surfaces. 5. Chemical Etching: Chemical etching is a process that selectively removes the surface layer of the aluminum sheet using a combination of chemicals. It is commonly employed to eliminate anodized coatings or to create decorative patterns. However, this method necessitates specialized equipment and expertise. It is important to consider the specific requirements of the aluminum sheet, the level of contamination, and the desired outcome when choosing a cleaning method. Consulting the manufacturer's guidelines or seeking professional advice is always recommended to ensure the most suitable and safe cleaning method is employed.

- Q: Are aluminum sheets suitable for use in HVAC (heating, ventilation, and air conditioning) systems?

- Yes, aluminum sheets are suitable for use in HVAC systems. Aluminum is a popular material choice for HVAC systems due to its various beneficial properties. Firstly, aluminum is lightweight yet strong, making it easy to handle and install in HVAC systems. Its low density also allows for cost-effective transportation and reduces the overall weight of the HVAC units. Secondly, aluminum has excellent corrosion resistance. HVAC systems often encounter moisture and condensation, especially in air conditioning units, and aluminum's resistance to corrosion ensures its durability and longevity in such environments. Additionally, aluminum sheets have good thermal conductivity, allowing for efficient heat transfer throughout the HVAC system. This property is particularly important in heating and cooling applications, as it helps to distribute the desired temperature effectively. Moreover, aluminum is a non-toxic material, making it safe for use in HVAC systems that circulate air throughout buildings. It does not release any harmful particles or gases into the air, ensuring the quality of indoor air. Lastly, aluminum is a highly recyclable material, making it environmentally friendly. The ability to recycle aluminum sheets reduces the carbon footprint associated with HVAC systems and aligns with sustainability goals. Considering all these advantages, aluminum sheets are indeed suitable for use in HVAC systems, providing an optimal balance of strength, corrosion resistance, thermal conductivity, safety, and environmental friendliness.

Send your message to us

Sheets of Honeycomb Aluminum Louver Gutter Roof Aluminium Composite Panel 1100 3003

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords