Gutter Roof Aluminium Composite Panel 1100 3003 PE PVEF Pre Painted

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Gutter Roof Aluminium Composite Panel 1100 3003 PE PVEF Pre Painted

Thickness | 0.1mm-10mm |

Popular Thickness | 0.1mm/0.2mm/0.25mm/0.3mm/0.6mm/0.8mm/1.0mm/1.2mm/1.5mm/2.0mm/3.0mm... |

Width | 20mm-2500mm |

inner diameter | 505mm 508mm 605mm |

Material | 1050,1060,1070,1100,1200,3003,3004,3005,5052,5005,5754,5083 |

Temper | O,H12,H14,H16,H18,H22,H24,H26,H32,H34,H36,H38,H111,H112 |

Surface | mill finish |

Packing | Export standard wooden pallets |

Payment Terms | 100% irrevocable L/C at sight or 30% T/T in advance as deposit,70% balance against the B/L copy |

Minimum Order Quantity | 5000kg |

Delivery time | 15-25 days after receiving L/C or deposit |

Remark | Specific requirement of alloy grade, temper or specification can be discussed at your request |

2. Application of Gutter Roof Aluminium Composite Panel 1100 3003 PE PVEF Pre Painted

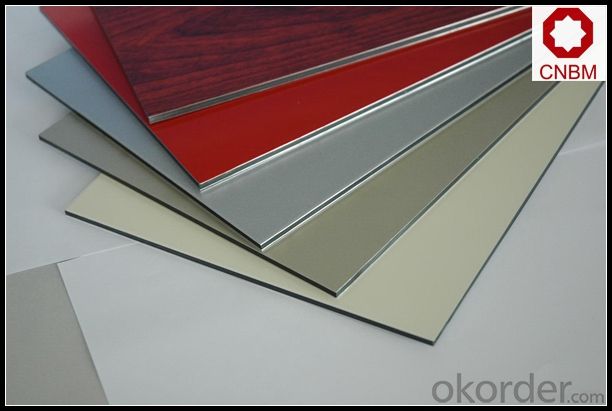

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Gutter Roof Aluminium Composite Panel 1100 3003 PE PVEF Pre Painted

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

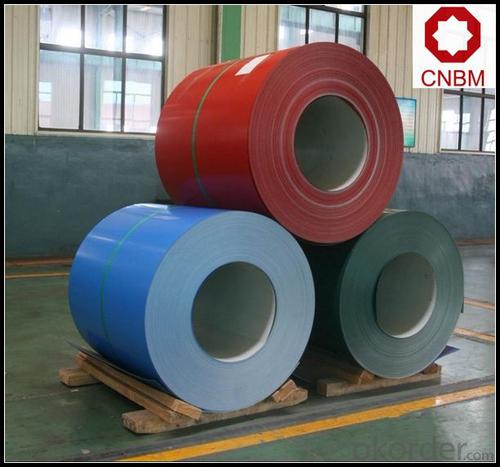

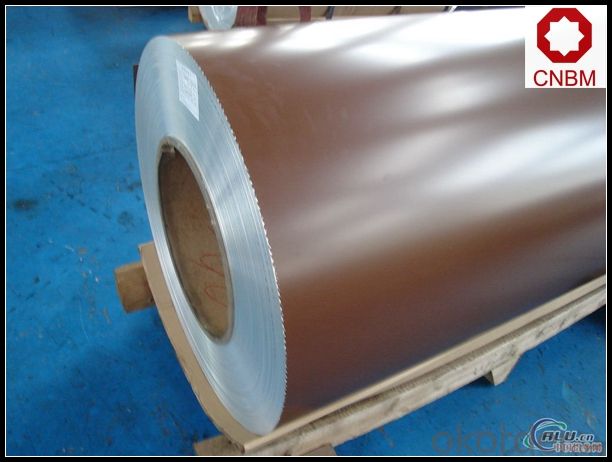

5. Image of Gutter Roof Aluminium Composite Panel 1100 3003 PE PVEF Pre Painted

6. Package and shipping of Gutter Roof Aluminium Composite Panel 1100 3003 PE PVEF Pre Painted

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: How are aluminum coils protected against bending and warping during storage?

- Aluminum coils are protected against bending and warping during storage through various measures and precautions. Firstly, the coils are typically stored in a horizontal position to evenly distribute the weight and minimize stress on the coil. This helps to prevent any bending or warping that could occur if the coils were stored vertically. Additionally, the coils are often wrapped in protective materials such as plastic or paper to provide a barrier against external forces that could cause damage. These protective wrappings help to cushion the coils and prevent any direct contact with hard surfaces that could result in bending or warping. Furthermore, it is common practice to stack the coils carefully and securely, ensuring that they are not overloaded or subjected to excessive pressure. This is done to maintain the structural integrity of the coils and prevent any deformation during storage. Temperature control is another important aspect in protecting aluminum coils against bending and warping. Extreme temperature fluctuations can cause the metal to expand or contract, potentially leading to warping. Therefore, the storage environment should be maintained at a stable temperature to minimize any thermal stress on the coils. Overall, a combination of proper handling, protective wrappings, secure stacking, and temperature control play crucial roles in preventing bending and warping of aluminum coils during storage. These measures ensure that the coils remain in optimal condition and are ready for use when needed.

- Q: Can aluminum coils be fabricated or machined?

- Aluminum coils have the ability to undergo fabrication or machining. They are commonly utilized in heating, ventilation, and air conditioning (HVAC) systems, automotive radiators, and electrical transformers. These coils can be tailored and machined according to specific requirements and dimensions. The fabrication of aluminum coils involves procedures such as cutting, bending, and welding in order to achieve the desired shape and size. This allows for customization and adaptation to various applications. Conversely, machining involves the removal of material from the aluminum coil through the use of cutting tools such as lathes, mills, or CNC machines. This process is employed to attain precise dimensions, smooth finishes, and intricate designs. In summary, aluminum coils possess versatility and can be fabricated or machined to accommodate diverse needs. The flexibility of aluminum as a material renders it a favored choice in numerous industries, offering durability, lightweight properties, and exceptional thermal conductivity.

- Q: Explain the distinctions between cold rolled aluminum coils and hot rolled aluminum coils, focusing on the manufacturing process and resulting properties.

- <p>Cold rolled aluminum coils are produced by rolling aluminum at room temperature, resulting in a smoother surface and tighter dimensional tolerances. They have higher strength and hardness due to cold working. Hot rolled aluminum coils, on the other hand, are rolled at high temperatures, which allows for larger thickness reductions and creates a rougher surface. Hot rolled coils are generally softer and more ductile, with lower strength and hardness compared to cold rolled coils. The choice between the two depends on the specific application requirements for strength, surface finish, and formability.</p>

- Q: How are aluminum coils tested for surface roughness?

- Aluminum coils are tested for surface roughness using various methods to ensure they meet the required quality standards. One commonly used method is the use of a surface roughness tester or profilometer. This instrument measures the roughness of the coil surface by running a stylus or probe across the surface and recording the variations in height. The surface roughness tester provides data such as Ra (average roughness), Rz (average peak-to-valley roughness), and Rt (total height roughness). These parameters help assess the surface quality of the aluminum coil and determine if it meets the desired specifications. Additionally, visual inspection is often conducted to detect any visible defects, scratches, or irregularities on the surface. This inspection can be done manually by trained operators or with the assistance of automated systems that use cameras and image analysis algorithms to detect imperfections. Another method used to evaluate surface roughness is the use of laser scanners. These scanners emit laser beams that reflect off the surface of the aluminum coil and are then measured to determine the surface profile and roughness. Laser scanners provide high-resolution, non-contact measurements, making them highly accurate and efficient for assessing surface roughness. Overall, a combination of surface roughness testers, visual inspection, and laser scanners are commonly employed to test the surface roughness of aluminum coils, ensuring they meet the required quality standards for various applications.

- Q: My favorite deodorant contains aluminum. It smells really good and it works really well.My mom doesn't like me using it because it contains aluminum.So I got aluminum free. It doesn't smell at all (I can't seem to find fragrant aluminum free deodorant) and it doesn't work as well, for some reason.I want to keep using the one with aluminum, but will it be harmful to me in the future?

- all of my deodorants have aluminum in them. practically every deodorant that works out there has aluminum in it. the only one i know of that DOESN'T have aluminum is Tom's Natural and it doesn't work at ALL. See the aluminum is the key ingredient that stops you from sweating and stops odor, that's why it works so much better than your new aluminum-free one. But then again, use it wisely, because it's linked to alzeimer's, brain cancer, etc.

- Q: Are aluminum coils suitable for heat exchangers?

- Aluminum coils are indeed a fitting choice for heat exchangers. This is because aluminum possesses exceptional thermal conductivity, making it highly efficient and effective in transferring heat between mediums. Its ability to swiftly transfer heat from one medium to another is particularly advantageous for heat exchangers that require efficient heat transfer. Furthermore, aluminum coils are lightweight, resistant to corrosion, and boast excellent durability. These qualities contribute to their popularity in a wide range of applications, including heat exchangers. The corrosion resistance of aluminum ensures that the coils can endure harsh environments and prevent the occurrence of rust or corrosion, thereby prolonging the heat exchanger's lifespan. Moreover, aluminum coils are easily moldable and can be shaped into various forms, allowing for flexibility in designing and constructing heat exchangers. This adaptability makes them suitable for a diverse array of applications, such as HVAC systems, refrigeration units, and automotive cooling systems. In conclusion, the high thermal conductivity, lightweight nature, corrosion resistance, durability, and versatility of aluminum coils make them well-suited for heat exchangers. These properties establish aluminum coils as an excellent choice for achieving efficient heat transfer in numerous industries.

- Q: Can aluminum coils be used in electrical cables?

- Yes, aluminum coils can be used in electrical cables. Aluminum is a commonly used material for electrical conductors due to its excellent electrical conductivity and relatively low cost compared to copper. It is especially used in power transmission and distribution cables where long-distance transmission is required. Aluminum coils are often used in overhead power lines and underground cables. However, it is important to note that aluminum has a lower tensile strength than copper, so the cables need to be properly designed and manufactured to ensure adequate mechanical strength. Additionally, aluminum conductors require larger cross-sectional areas compared to copper to achieve the same electrical performance, which can result in slightly larger cable sizes.

- Q: so i have a dirtbike and i wanted to polish the swing arm.i have 100 grit,400,800 and 1200.i use to 100 to take off the coating the swing arm has and once its off its like a natural aluminum left.well i polished it before and it came out real good to a mirror finish.well i did the other half of the swing arm exactly the same even with new sand paper and it just didnt shine like the other half!i wet sanded it and i used car wax as my buffing compound,yes i used a soft buffing wheel.the car wax works really good!thats how i got the first half to a mirror shine but the other half just wasnt working for me.any suggestions?oh and i sanded in all one direction.

- Use 1200 to 2000 grit. Your sandpaper is way too course! The paper probably got gummed up With aluminum particals. Use water or oil to wash away particals. In other words wet sand it. Then get this polish called Mothers Aluminum Polish. And two micro fiber cloths. Use the mothers and wipe off with first towel. Then use second towel. Trust me! I spend alot of time in my machine shop making custom aluminum parts. If you can trickle water over the surface of what your polishing it helps. The 1200 to 2000 grit can be purchased at Walmart in the auto section.

- Q: This question asks about the environmental impact of aluminum coils, which are commonly used in various industries.

- <p>Aluminum coils have both positive and negative environmental impacts. On the positive side, aluminum is highly recyclable, and its use in coils reduces the need for raw material extraction, thus conserving natural resources. The recycling process also consumes less energy compared to primary aluminum production, reducing greenhouse gas emissions. However, the production of aluminum coils involves energy-intensive processes that can contribute to carbon emissions. Additionally, if not properly managed, the waste from aluminum production can pollute water bodies and soil. Overall, the environmental impact depends on the balance between recycling and production practices, as well as waste management.</p>

- Q: What are the weight savings achieved by using aluminum coils?

- Compared to materials like steel, significant weight savings can be achieved by using aluminum coils. Aluminum, a lightweight metal with a density approximately one-third that of steel, allows for greatly reduced overall weight when utilizing aluminum coils instead of steel coils. The benefits of weight savings attained through aluminum coil usage are numerous. In industries such as automotive and aerospace, reducing weight is crucial for enhancing fuel efficiency and increasing payload capacity. Lighter vehicles and aircraft require less energy for operation and can accommodate more passengers or cargo, resulting in cost savings, improved performance, and minimized environmental impact. Moreover, the weight savings obtained from aluminum coils can provide practical advantages in other applications as well. For instance, in HVAC systems, lighter coils facilitate easier installation and transportation, thereby reducing labor and logistics costs. The actual weight savings achieved by utilizing aluminum coils will vary depending on the specific application and design specifications. Nonetheless, it is widely acknowledged that aluminum coils offer a significant weight advantage over alternative materials. The actual weight savings can range from 30% to 70% or more, depending on the specific comparison being made. To summarize, the weight savings achieved through the use of aluminum coils can be substantial. This lightweight material offers numerous benefits in terms of fuel efficiency, payload capacity, performance, and cost savings. When prioritizing weight reduction, aluminum coils are an excellent choice for a wide range of industries and applications.

Send your message to us

Gutter Roof Aluminium Composite Panel 1100 3003 PE PVEF Pre Painted

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords