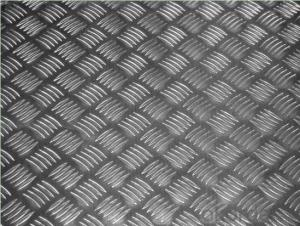

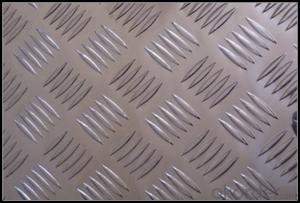

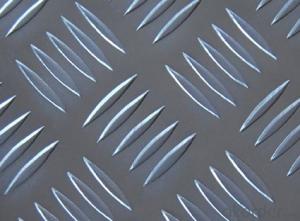

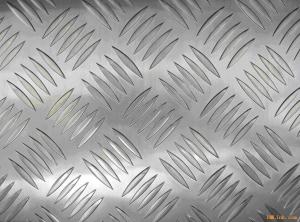

Colored Sheets of Aluminum - 5 Bars Decorative Skid Resistant Aluminum Sheets

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

5 bars decorative aluminum sheet skid resistance

ALLOY : AA1***(AA1050,AA1060,AA1070,AA1100etc)

AA3***(AA3003,AA3004,AA3005,AA3105etc)

AA5***(AA5052 etc)

TEMPER:H14,H18,H24,H26,H32

THICKNESS:0.2mm-20mm

WIDTH:10mm-1500mm

EMBOSSED PATTERNS : Diamond, stucoo,bars etc

STANDARD: GB/T3880-2006

Special specification is available on customer's requirement

Product Description

Goods name | Aluminum plate |

alloy | Yes |

Plance of origin | China |

Quality | Prime quality |

Certificate | ISO9001 |

Grade | 3000 Series |

Thickness | 0.3-150mm |

Type | Plate |

Width | 300-1950mm |

Model number | 3003,3004,3005,3014,3105 |

Surface | Mill finish |

Temper | O-H112 |

Ensure | we can supply customers' with different specifications of the highest quality and lowest price. Sincerely welcome to contact us for the future details if any item interest you ,and we will make every effort to assure that your requirements will be satisfied,and we hope to establish long-term business relations with you on the basis of the equality and mutual benefit. |

- Q: What are the advantages of using aluminum sheets in the packaging industry?

- There are several advantages of using aluminum sheets in the packaging industry. Firstly, aluminum is a lightweight material, which makes it easier to handle and transport. Secondly, aluminum is highly resistant to corrosion, ensuring the protection of the packaged products. Additionally, aluminum has excellent barrier properties, providing a strong barrier against light, moisture, and oxygen, thus extending the shelf life of the packaged goods. Moreover, aluminum is malleable, allowing for easy shaping and customization of packaging designs. Lastly, aluminum is recyclable, making it a sustainable choice for the packaging industry and contributing to environmental conservation efforts.

- Q: Are 101 aluminum sheets suitable for automotive applications?

- Yes, 101 aluminum sheets are suitable for automotive applications.

- Q: hi my house is wired with aluminum wire and we have this light that has been changed 6 times because originally there was a cheap builders light up there that got replaced with a ceiling fan but the ceiling fan was replaced a couple of times since the remote never worked properly on any of the cieling fans so finally we replaced the cieling fan with just a normal light but now the socket got cracked on the new light by accident. The problem is im wondering if it is safe to put another light up because i have heard aluminum wire breaks easy and the wires have been moved around alot. But if i dont replace the light i wont have a light. We also use the correct wire nuts and anti oxidant on the connections. Also when the 4 cieling fans that had been put up were wired correctly since i have put up many cieling fans up without remotes before. Also Is there a certain number of times aluminum or copper wire can be bent with out having to worry about a fire happening or the wire breaking.

- OK. the first thing is that you can connect copper to aluminum. They make wire that is called copper clad aluminum and is exactly what it sounds like, but you don't have to install that. So if you want to install a junction box just make sure that it remains exposed and that you secure the wire within 12 inches of the box. About your light. I would simply put up another fixture, just make a visual inspection of the wire. if it is all roughly the same shade then it is most likely still fine. The only damage that is done by replacing a fixture to much is to the wire that is inside of the box and if something happens to that it will not start a fire, the light simply won't work.

- Q: What will reflect light more- aluminum foil or white paper?

- aluminum foil reflects light more. you can almost see your reflection in foil while does not do that.

- Q: What is the typical wear resistance of aluminum sheets?

- The typical wear resistance of aluminum sheets can vary depending on the specific alloy and temper of the sheet. Generally, aluminum sheets have a moderate wear resistance compared to other metals. However, they are not as wear-resistant as materials such as steel or titanium. Aluminum sheets can withstand light to moderate wear and abrasion, making them suitable for applications where they are not subjected to excessive friction or impact. To enhance the wear resistance of aluminum sheets, they can be treated with coatings or surface treatments such as anodizing or painting. Additionally, the thickness and hardness of the aluminum sheet can also affect its wear resistance, with thicker and harder sheets generally offering better resistance to wear.

- Q: Do the aluminum sheets come with a protective coating?

- Yes, the aluminum sheets come with a protective coating. The protective coating is applied to prevent scratches, corrosion, and other damages during transportation and handling. This coating ensures that the aluminum sheets are delivered to the customers in pristine condition.

- Q: Are aluminum sheets suitable for architectural canopies?

- Architectural canopies can indeed be made using aluminum sheets. Aluminum is a popular material choice for architectural applications because of its lightweight nature, durability, and flexibility. It possesses a high strength-to-weight ratio, making it capable of enduring various weather conditions and providing stability for canopies. Moreover, aluminum is highly resistant to corrosion, ensuring that the architectural canopy remains visually appealing and functional for an extended period. Its malleability allows for easy fabrication and customization, enabling architects and designers to create unique and intricate canopy designs. Additionally, aluminum is an environmentally friendly option as it can be recycled, contributing to sustainable construction practices. All in all, aluminum sheets are a dependable and versatile choice for architectural canopies.

- Q: This question asks if aluminum sheets are suitable for outdoor use in environments with high temperatures.

- <p>Yes, aluminum sheets can be used for outdoor applications even in high temperatures. Aluminum has a high melting point of around 660掳C (1220掳F), making it resistant to heat. It also has good thermal conductivity, which allows it to dissipate heat quickly. However, it's important to note that prolonged exposure to high temperatures can cause aluminum to expand and potentially warp. For outdoor applications, especially in high-temperature environments, it's recommended to use aluminum alloys designed for such conditions to ensure durability and performance.</p>

- Q: Are aluminum sheets resistant to saltwater corrosion?

- Yes, aluminum sheets are generally resistant to saltwater corrosion. Aluminum has a natural ability to form a protective oxide layer when exposed to air or water, including saltwater. This oxide layer acts as a barrier, preventing further corrosion and protecting the underlying metal. Additionally, aluminum is lightweight and durable, making it a popular choice for various marine applications such as boats, shipbuilding, and offshore structures. However, it is important to note that the resistance to saltwater corrosion can vary depending on the specific alloy and surface treatment of the aluminum sheets. Therefore, proper selection of the appropriate alloy and protective coatings can further enhance the corrosion resistance of aluminum sheets in saltwater environments.

- Q: Can aluminum sheets be used for protective barriers?

- Aluminum sheets are indeed suitable for protective barriers. Being both lightweight and durable, aluminum possesses exceptional strength and corrosion resistance. Its utilization is widespread across a multitude of contexts necessitating protection, such as construction sites, industrial facilities, and military installations. By effortlessly undergoing fabrication and shaping, aluminum sheets can be transformed into robust barriers that effectively impede unauthorized access and offer protection against potential hazards. Furthermore, aluminum demonstrates remarkable versatility as it can be combined with materials like glass or steel to heighten its protective capabilities. All in all, due to their strength, durability, and versatility, aluminum sheets represent a dependable choice for protective barriers.

Send your message to us

Colored Sheets of Aluminum - 5 Bars Decorative Skid Resistant Aluminum Sheets

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords