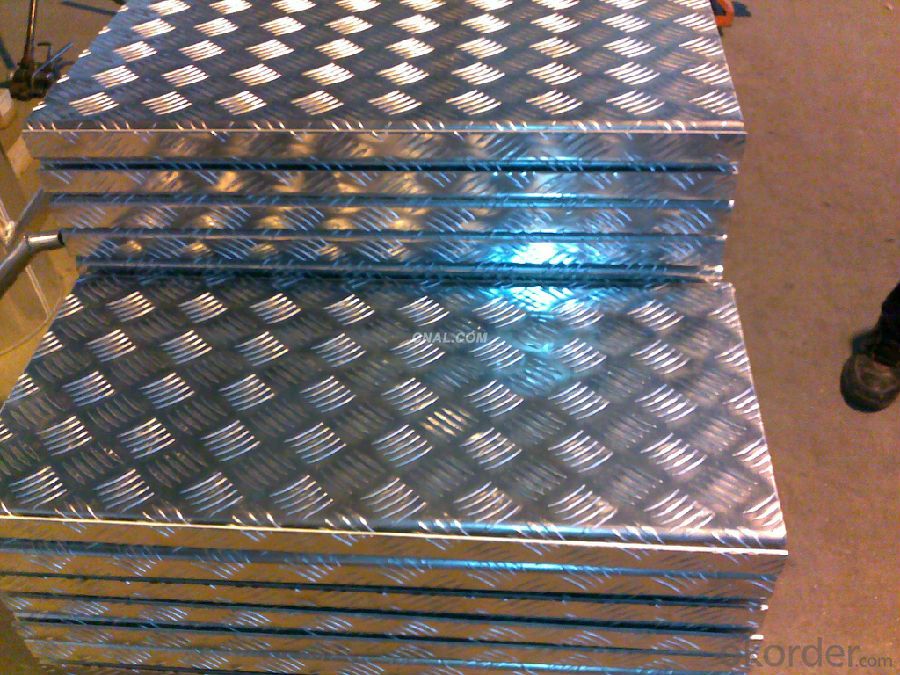

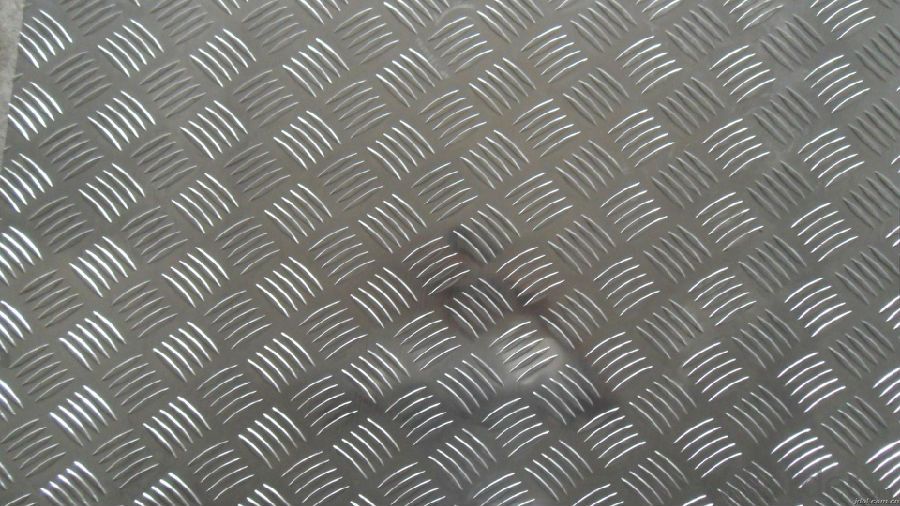

Sheets of Aluminum for Skid Resistance Application with Five Bars

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminium FIve Bars for Skid Resistance Application Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium FIve Bars for Skid Resistance Application:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

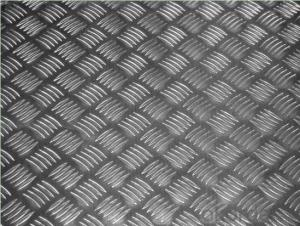

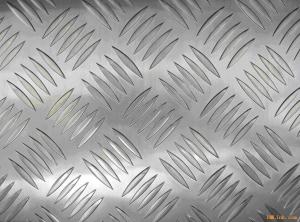

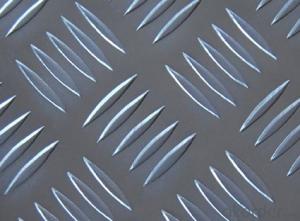

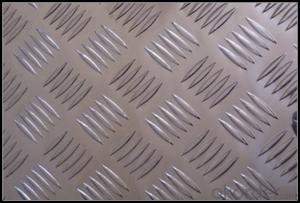

Images of the Aluminium FIve Bars for Skid Resistance Application:

Aluminium FIve Bars for Skid Resistance Application Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ Aluminium FIve Bars for Skid Resistance Application:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: Can anyone tell me what to be careful of if you have aluminum wiring in your house. I was told that if the wall gets hot, I need to tighten the screws of the inside switch. Is this true and if I didn't, would it actually cause a fire in the wall. If this is true, how often does it loosen?

- Several answers are very good but the one thing that evrybody failed to mention is each device (switch, recept, fixture, etc.) must be listed to use with AL wire. This is the biggest problem I find. Home owners run out to the local hardware and pick up a new device and do not check the listings. The copper wire pig tail is an option but once again you must use a wire nut that is listed for both AL CU wiring. Most are a dark purple in color. Electrical Inspector

- Q: Can aluminum sheets be an alternative to wood in certain applications?

- Yes, aluminum sheets can definitely be an alternative to wood in certain applications. Aluminum has many advantages over wood, making it a popular choice in various industries. Firstly, aluminum is highly durable and long-lasting, as it is resistant to corrosion, rot, and pests. This makes it ideal for outdoor applications or areas with high moisture content. Additionally, aluminum sheets are lightweight, making them easier to handle and transport compared to wood. They also have high strength-to-weight ratio, meaning they can withstand heavy loads without compromising structural integrity. Furthermore, aluminum is a sustainable material as it can be recycled indefinitely without losing its properties. In contrast, wood requires cutting down trees, which has environmental implications. Aluminum sheets also offer design flexibility, as they can be easily shaped, bent, and formed into complex structures, allowing for creative and innovative applications. Moreover, aluminum has excellent thermal and electrical conductivity, making it suitable for applications where heat dissipation or electrical conductivity is important. Despite these advantages, it is important to note that wood still has its unique characteristics and benefits in certain applications. Wood creates a warm and natural aesthetic that aluminum cannot replicate, and it is often preferred in interior design or furniture manufacturing. Additionally, wood is a renewable resource and has excellent insulating properties, which can be advantageous in construction or insulation applications. Therefore, while aluminum sheets can be a great alternative to wood in many cases, the choice ultimately depends on the specific requirements and desired outcomes of the application.

- Q: Can aluminum sheets be used for balcony railings?

- Indeed, balcony railings can be constructed using aluminum sheets. Aluminum is widely favored for balcony railings because of its lightweight properties, durability, and resistance to corrosion. This adaptable material can be effortlessly molded into various shapes and designs, making it suitable for a range of architectural styles. Moreover, aluminum railings necessitate minimal upkeep and can endure inclement weather conditions, rendering them an astute and enduring selection for balcony railings.

- Q: Aluminum and oxygen gas react to produce aluminum oxide

- Aluminium oxide is Al2O3, so there are 3 oxygen atoms for every 2 aluminium atoms. Divide 75 by the relative atomic mass of oxygen (15.9994). That is proportional to the number of oxygen atoms. Then divide by 3 and multiply by 2. This gives a number proportional to the number of aluminium atoms. Then multiply this by the relative atomic mass of aluminium (26.981529) to give the mass of aluminium required in grams.

- Q: What are the different methods for joining aluminum sheets?

- There are several methods for joining aluminum sheets, depending on the specific application and desired outcome. Some of the common methods include: 1. Welding: Aluminum can be welded using various techniques such as Tungsten Inert Gas (TIG) welding, Metal Inert Gas (MIG) welding, and Resistance Spot Welding (RSW). TIG welding is commonly used for thin aluminum sheets, providing a strong and precise joint. MIG welding is suitable for thicker sheets and offers faster production rates. RSW involves passing an electric current through the sheets, melting the aluminum at the contact points, and then applying pressure to create a solid joint. 2. Mechanical Fasteners: Bolts, nuts, and screws can be used to join aluminum sheets together. They provide a strong and reliable connection that can be easily disassembled if needed. Rivets are another common mechanical fastening method, where a rivet gun is used to secure the sheets by deforming the rivet. 3. Adhesive Bonding: Specialized adhesives designed for aluminum bonding can be used to join sheets together. This method is often used when aesthetics are important, as it provides a clean and seamless appearance. Adhesive bonding also distributes the stress evenly across the joint, reducing the risk of localized stress concentration. 4. Clinching: Clinching is a cold joining process where a punch is used to deform the aluminum sheets, creating a mechanical interlock. This method is quick, cost-effective, and does not require additional materials like fasteners or adhesives. 5. Friction Stir Welding (FSW): FSW is a solid-state joining process that uses a rotating tool to generate friction between the aluminum sheets. The friction heats the material, making it pliable, and the rotating tool then stirs the softened material together to form a solid joint. FSW is particularly suitable for joining thicker aluminum sheets. Each joining method has its own advantages and disadvantages, and the choice depends on factors such as the desired strength, appearance, production rate, and the specific requirements of the application.

- Q: Are aluminum sheets suitable for aerospace structural components?

- Yes, aluminum sheets are suitable for aerospace structural components. Aluminum is a lightweight and durable material that has been widely used in the aerospace industry for many years. It possesses excellent strength-to-weight ratio, making it highly desirable for various applications in aircraft manufacturing. Aluminum sheets offer several advantages for aerospace structural components. Firstly, they are lightweight, which helps reduce the overall weight of the aircraft. This is crucial for improving fuel efficiency, increasing payload capacity, and enhancing the performance of the aircraft. Additionally, the lightweight nature of aluminum sheets allows for easier handling and assembly during the manufacturing process. Secondly, aluminum has excellent corrosion resistance properties. This is crucial for aerospace applications as the components are exposed to various environmental conditions, such as high humidity, extreme temperatures, and exposure to chemicals. The corrosion resistance of aluminum ensures the longevity and durability of the structural components, reducing the need for frequent maintenance and replacement. Furthermore, aluminum is a highly malleable material, allowing for easy shaping and forming into complex structures. It can be easily bent, cut, and fabricated to meet specific design requirements, making it versatile for various aerospace applications. The ability to form complex shapes with aluminum sheets enables engineers to design efficient and streamlined structures, optimizing aerodynamics and minimizing drag. Another advantage of aluminum sheets is their excellent thermal conductivity. This property allows for efficient heat dissipation, which is crucial in aerospace applications where components may be exposed to high temperatures generated during flight or engine operation. The thermal conductivity of aluminum helps prevent overheating and ensures the structural integrity of the components. In conclusion, aluminum sheets are highly suitable for aerospace structural components due to their lightweight, corrosion resistance, malleability, and thermal conductivity properties. These characteristics make aluminum an ideal material for various applications in the aerospace industry, contributing to the overall performance, efficiency, and safety of aircraft.

- Q: Is it possible to utilize aluminum sheets as materials for car body panels?

- <p>Yes, aluminum sheets can be used for car body panels. They offer several advantages such as lightweight, high strength, and good corrosion resistance. Aluminum is also easily recyclable and can be shaped into complex designs. However, aluminum is less resistant to dents compared to steel, which is a common material for car body panels. Despite this, aluminum's benefits often outweigh its drawbacks, making it a popular choice in the automotive industry, especially for high-performance and electric vehicles where weight reduction is crucial.</p>

- Q: This question asks if aluminum sheets are suitable for outdoor use in environments with high temperatures.

- <p>Yes, aluminum sheets can be used for outdoor applications even in high temperatures. Aluminum has a high melting point of around 660掳C (1220掳F), making it resistant to heat. It also has good thermal conductivity, which allows it to dissipate heat quickly. However, it's important to note that prolonged exposure to high temperatures can cause aluminum to expand and potentially warp. For outdoor applications, especially in high-temperature environments, it's recommended to use aluminum alloys designed for such conditions to ensure durability and performance.</p>

- Q: Are aluminum sheets magnetic?

- Aluminum sheets lack magnetic properties and do not exhibit any attraction or interaction with magnets. This is due to the absence of magnetic elements like iron or nickel in aluminum, making it a non-magnetic metal.

- Q: My new home has a mix of copper and aluminum wiring. My mother used a shop vac in one of the recepticles last week and blew two of them in my bedroom. Then this weekend my brother was replacing my exhaust fan in the bathroom and that proceeded to blow the entire bedroom and bathroom including ceiling fans, lights and all recepticles. Does anyone have any ideas?

- It is very common in older homes to have tin coated copper wiring which many people then think they have aluminum wiring. If you have a piece of the older wiring or can turn the breaker off to one of these wires use a screw driver to scrape at the wire on the bare end; if it's tin coated copper you will see the orange/rust color of copper after a few light scrapes, the scaping is nothing agressive. This will determine if you have aluminum or not. Someone else mentioned about a loose connection which if a copper wire aluminum wire are connected together it would very likely fail creating a short. The two different materials expand contract at different rates which creates a bad connection. There is a special crimp process that can be done to join the two but a electrician should definately do this. A lot of the older homes just have two many items all on one breaker. With what you've described I would suggest using a electrician. Additional: If no breakers are tripped off and you do not have power in some areas you might have another panel (sub-panel) somewhere else in the home OR this circuit is hooked up to a GFI outlet somewhere else such as the kitchen, bathroom or garage. I would physically re-check each breaker and then hunt for a GFI outlet and sub-panel.

Send your message to us

Sheets of Aluminum for Skid Resistance Application with Five Bars

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords