409 410 stainless steel sheetsCold rolled/hot rolled

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

410 and 430 stainless steel sheet

1.Description of products

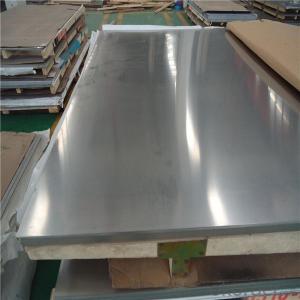

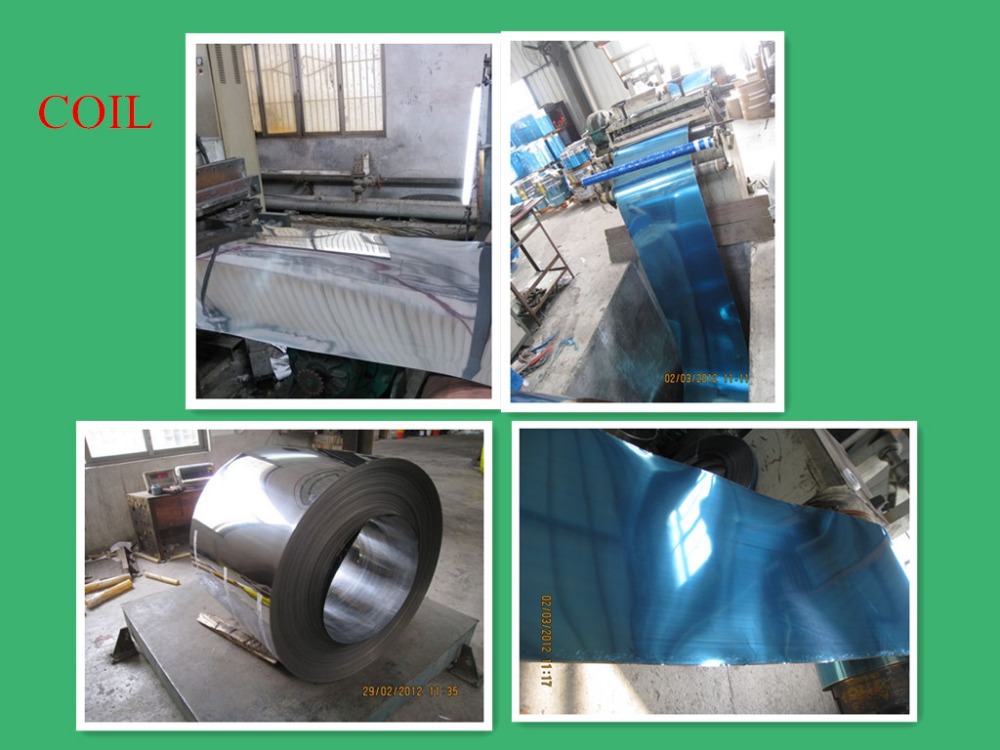

| Item: | Cold rolled stainless steel coil |

| Grade: | 410 430 |

| Standard: | JIS,AISI,ASTM,GB,DIN, |

| Thickness: | 0.16mm-2.0mm |

| Width: | max:1080mm |

| Place of Orgin: | Jieyang,China(Mainland) |

| Brand name: | baosteel , lisco,tisco,jisco |

| Type: | Plate,Coil,Circle,Sheet |

| Application: | Building ,household appliance. kitchen utensiles, industry and medical equipment,electric cooker etc. |

| Technical processing: | Cold rolled |

| Surface: | BA, 8K ,NO.4, mirror, hairline according to customer's request. |

| Certificate: | the third inspections |

| Port: | SHENZHEN, SHANTOU |

| Packaging Details: | Export standard package |

| Delivery Time: | About 10-30 days |

| Payment Terms: | T/T,Irrevocable L/C at sight,D/P |

| Supply Ability: | 2500Ton-3000Ton/per Month |

2. Products

Application

Building, elevator decoration,

household appliance. kitchen utensiles

6.Tips

If you are interested in our products,please tell us about the type,finish,size,thickness ,QTY and terms of shipment so that we can make an exact and favorable quotation for you.

Our philosophy:“Quality First”, advanced equipments together with experienced technicians ,hope we will have a chance to work for you,welcome to inquiry.

- Q: Are stainless steel sheets resistant to humidity?

- Yes, stainless steel sheets are resistant to humidity. Stainless steel is known for its excellent corrosion resistance properties, which includes resistance to moisture and humidity. This makes stainless steel sheets a suitable material for various applications in humid environments such as kitchens, bathrooms, and outdoor structures. The chromium content in stainless steel creates a protective layer of chromium oxide on the surface, which acts as a barrier against moisture, preventing it from penetrating the material and causing corrosion. Additionally, stainless steel sheets are often used in industries like food processing and pharmaceuticals where cleanliness and hygiene are crucial, and their resistance to humidity ensures their durability and longevity in such environments. Overall, stainless steel sheets are a reliable and durable option for humid conditions due to their inherent resistance to moisture and corrosion.

- Q: Can stainless steel sheets be used for decorative panels?

- Yes, stainless steel sheets can be used for decorative panels. The versatility, durability, and sleek appearance of stainless steel make it a popular choice for various decorative applications, including panels. It can be used to create modern and stylish designs in both residential and commercial settings.

- Q: How do I prevent rusting on stainless steel sheets?

- To prevent rusting on stainless steel sheets, there are several steps you can take: 1. Keep the surface clean: Regularly clean the stainless steel sheets using a mild detergent or stainless steel cleaner. This will help remove any dirt, grime, or contaminants that could lead to corrosion. 2. Avoid abrasive cleaners: Avoid using harsh or abrasive cleaners, as they can scratch the surface of the stainless steel, making it more susceptible to rusting. Stick to non-abrasive cleaning solutions and soft cloths or sponges. 3. Remove rust promptly: If you notice any signs of rust on the stainless steel sheets, it is important to address it immediately. Use a stainless steel cleaner or a mixture of vinegar and water to gently remove the rust. Rinse thoroughly and dry the surface afterwards. 4. Protect against moisture: Stainless steel is resistant to rust, but it can still corrode in the presence of moisture. To prevent this, ensure that the stainless steel sheets are properly installed and sealed to protect against water or moisture infiltration. Avoid leaving standing water on the surface and promptly dry any spills or moisture. 5. Apply a protective coating: Consider applying a protective coating to the stainless steel sheets to provide an extra layer of protection against rust. There are various sealants and coatings available specifically designed for stainless steel that can help prevent corrosion. 6. Regular maintenance: Regularly inspect the stainless steel sheets for any signs of damage, rust, or corrosion. Address any issues promptly to prevent further damage. Additionally, perform routine cleaning and maintenance to keep the surface in optimal condition. By following these preventive measures, you can significantly reduce the chances of rusting on stainless steel sheets and maintain their longevity and aesthetic appeal.

- Q: Are stainless steel sheets suitable for electrical enclosures?

- Indeed, electrical enclosures can be made using stainless steel sheets. Stainless steel possesses remarkable attributes such as exceptional strength, resistance to corrosion, and durability, rendering it a perfect material for safeguarding electrical components. It affords a superior level of safeguarding against environmental factors like moisture, dust, and extreme temperatures. Furthermore, stainless steel boasts commendable electrical conductivity, which is indispensable for proper grounding and shielding. It also provides a good degree of electromagnetic compatibility (EMC), thereby diminishing the likelihood of electromagnetic interference (EMI) in delicate electrical equipment. Additionally, stainless steel can be effortlessly cleaned and maintained, guaranteeing a long-lasting and dependable enclosure for electrical applications.

- Q: Can stainless steel sheets be used for swimming pool installations?

- Yes, stainless steel sheets can be used for swimming pool installations. Stainless steel is a highly durable and corrosion-resistant material, making it suitable for use in swimming pools. It is resistant to rust, stains, and chemicals commonly found in pool water, making it a reliable choice for long-term use. Stainless steel sheets are often used for pool walls, floors, and other structural components because they can withstand the harsh conditions associated with pool environments. Additionally, stainless steel has a sleek and modern appearance, adding to the overall aesthetics of the pool.

- Q: What's the difference between stainless steel 302 and 304?

- 302 stainless steel and 304 stainless steel are suitable for food processing, storage and transportation. It has good processability and weldability.

- Q: What is the electrical resistance of stainless steel sheets?

- The electrical resistance of stainless steel sheets can vary depending on various factors such as the grade of stainless steel, its thickness, and the specific properties of the alloy used. Generally, stainless steel is known to have a relatively high electrical resistance compared to other metals. This is due to its composition, which includes a significant amount of chromium and other alloying elements that hinder the flow of electric current. However, the exact value of electrical resistance can range from a few micro-ohms per square meter to several ohms per square meter, depending on the specific grade and thickness of the stainless steel sheet. Therefore, it is crucial to consult the manufacturer's specifications or conduct specific electrical resistance tests to obtain accurate values for a particular stainless steel sheet.

- Q: How do you remove water stains from stainless steel sheets?

- To remove water stains from stainless steel sheets, you can try using vinegar or lemon juice. Apply either of these ingredients onto the stained area, let it sit for a few minutes, and then gently rub the stain with a soft cloth or sponge. Rinse the area with water and dry it thoroughly. If the stain persists, you can also consider using a stainless steel cleaner specifically designed for removing water stains.

- Q: How do you prevent discoloration or staining on stainless steel sheets?

- To prevent discoloration or staining on stainless steel sheets, there are several steps you can take: 1. Regular Cleaning: Clean the stainless steel sheets regularly using mild soap or detergent and warm water. Avoid using abrasive cleaners or scrub brushes that can scratch the surface. After cleaning, rinse thoroughly with clean water and dry with a soft cloth to prevent water spots. 2. Avoid Harsh Chemicals: Avoid using harsh chemicals such as bleach, ammonia, or chlorine-based cleaners on stainless steel sheets. These chemicals can cause discoloration or staining. Instead, opt for stainless steel-specific cleaners or natural cleaners like vinegar or lemon juice. 3. Proper Storage: Store stainless steel sheets in a clean and dry environment to avoid exposure to moisture or humidity. Moisture can lead to corrosion or rust, which can cause discoloration. If the sheets are stored outdoors, cover them properly to protect them from rain or snow. 4. Use Protective Coatings: Applying a protective coating or sealant on stainless steel sheets can help prevent discoloration or staining. There are various products available in the market specifically designed for stainless steel protection. Follow the manufacturer's instructions for application and reapplication, if necessary. 5. Avoid Contact with Reactive Metals: Avoid contact between stainless steel sheets and other reactive metals such as iron, copper, or aluminum. When these metals come into contact with stainless steel, a chemical reaction called galvanic corrosion can occur, leading to discoloration and staining. Ensure separation or isolation between stainless steel and reactive metals. 6. Regular Maintenance: Regularly inspect the stainless steel sheets for any signs of discoloration, staining, or damage. Address any issues promptly to prevent further deterioration. If you notice any stubborn stains, use a non-abrasive stainless steel cleaner and a soft cloth to gently rub the affected area in the direction of the grain. By following these preventive measures, you can maintain the appearance and integrity of stainless steel sheets, ensuring they remain free from discoloration or staining for an extended period.

- Q: What are the benefits of using perforated stainless steel sheets?

- Perforated stainless steel sheets offer several benefits. Firstly, they provide excellent ventilation and airflow, making them ideal for applications where aeration is crucial, such as in HVAC systems or industrial structures. Secondly, the perforations allow for enhanced visibility, enabling the passage of light and maintaining a clear line of sight. Additionally, the perforations can aid in noise reduction by absorbing sound waves. Lastly, stainless steel sheets are highly durable, corrosion-resistant, and easy to maintain, making them a cost-effective solution for various industries.

Send your message to us

409 410 stainless steel sheetsCold rolled/hot rolled

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords