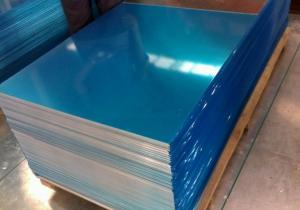

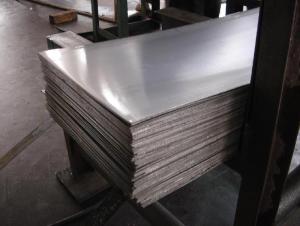

403 cold rolled stainless steel sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

grade | 430 |

surface | 2B |

thickness | 1MM, |

width | 1200MM,1220MM,1500MM,ETC. |

length | 2400MM,2440MM,3000MM,ETC. |

Payment terms | T/T, or L/C. |

Delivery time | Normally within 1 weeks after get your deposits. |

package | Standard export package, normally with wooden pallets |

MOQ | 5 tons/each size |

- Q: Are stainless steel sheets good for cryogenic storage?

- Yes, stainless steel sheets are commonly used for cryogenic storage due to their excellent properties. Stainless steel is known for its high strength, durability, and resistance to corrosion, making it suitable for extreme temperature environments like cryogenic storage. Additionally, stainless steel can maintain its mechanical properties even at very low temperatures, ensuring the safety and integrity of the stored materials. Moreover, stainless steel sheets offer good thermal conductivity, allowing for efficient heat transfer during cryogenic processes. Therefore, stainless steel sheets are a reliable choice for cryogenic storage applications.

- Q: Are stainless steel sheets suitable for pharmaceutical cleanrooms?

- Yes, stainless steel sheets are highly suitable for pharmaceutical cleanrooms. Stainless steel is widely used in the pharmaceutical industry due to its excellent resistance to corrosion, durability, and ease of cleaning. It is a non-porous material that does not harbor bacteria or contaminants, making it ideal for cleanroom environments where maintaining a sterile and hygienic environment is crucial. Stainless steel sheets are also easy to sanitize and withstand harsh cleaning agents without deteriorating or releasing particles that could contaminate the pharmaceutical products being manufactured. Additionally, stainless steel has a smooth and non-shedding surface, which prevents the accumulation of particles and facilitates cleanroom maintenance. Overall, stainless steel sheets are an excellent choice for pharmaceutical cleanrooms to ensure compliance with strict cleanliness and sterility requirements.

- Q: Are stainless steel sheets suitable for outdoor signage?

- Yes, stainless steel sheets are suitable for outdoor signage. Stainless steel is a popular choice for outdoor applications due to its durability, corrosion resistance, and aesthetic appeal. It is highly resistant to rust and can withstand harsh weather conditions, making it ideal for outdoor signage that needs to withstand exposure to rain, sunlight, and extreme temperatures. Additionally, stainless steel sheets can be easily customized and fabricated to create various designs and shapes, making it a versatile material for outdoor signage. Its sleek and polished finish also adds a professional and modern look to any signage. Overall, stainless steel sheets are a reliable and long-lasting option for outdoor signage.

- Q: Are stainless steel sheets good for pressure vessels?

- Yes, stainless steel sheets are indeed good for pressure vessels. Stainless steel is known for its excellent corrosion resistance, strength, and durability, making it an ideal material for containing fluids or gases under high pressure. It can withstand extreme temperatures and is resistant to chemicals, making it a reliable choice for pressure vessel applications in various industries such as oil and gas, chemical processing, and food processing.

- Q: What are the different surface textures available for stainless steel sheets?

- There are several different surface textures available for stainless steel sheets, including brushed, mirror, satin, embossed, and patterned.

- Q: Can stainless steel sheets be used for elevator handrails?

- Indeed, elevator handrails can utilize stainless steel sheets. The utilization of stainless steel for handrails is prevalent owing to its endurance, robustness, and immunity to rust. Elevator handrails endure incessant usage and exposure to diverse elements, rendering stainless steel an exemplary selection. Moreover, stainless steel can be effortlessly cleansed and upheld, guaranteeing a sanitary and visually pleasing atmosphere for elevator occupants.

- Q: Are stainless steel sheets scratch resistant?

- Indeed, stainless steel sheets possess a general resistance to scratches. Renowned for its robustness and ability to resist scratching, stainless steel is widely favored for a multitude of purposes. Nevertheless, it is crucial to acknowledge that stainless steel is not entirely impervious to scratches. Deep or abrasive scratches can still arise, particularly if the surface encounters harsh or abrasive substances. To minimize the likelihood of scratches and preserve the allure of stainless steel sheets, it is advisable to engage in regular maintenance and exercise caution by refraining from utilizing abrasive cleansers or scrubbing pads.

- Q: What is the maximum width of a stainless steel sheet?

- The maximum width of a stainless steel sheet typically depends on the manufacturing capabilities and equipment used by the stainless steel sheet manufacturer. However, in general, stainless steel sheets are available in a wide range of widths to meet various industry and application requirements. Common standard widths for stainless steel sheets can vary from 36 inches (91.44 cm) to 72 inches (182.88 cm) or even wider. Additionally, some manufacturers may offer custom cutting services to provide stainless steel sheets with even larger widths based on specific customer needs. It is always advisable to consult with the manufacturer or supplier to determine the maximum width options available for the specific stainless steel sheet desired.

- Q: Are stainless steel sheets suitable for pharmaceutical applications?

- Indeed, pharmaceutical applications find stainless steel sheets to be highly suitable. The pharmaceutical industry extensively employs stainless steel due to its exceptional resistance to corrosion, hygienic qualities, and effortless cleanability. It remains non-reactive, guaranteeing the purity of pharmaceutical products by preventing any interaction with drugs or chemicals. Moreover, stainless steel sheets exhibit resistance to elevated temperatures, a pivotal aspect for sterilization procedures. Additionally, stainless steel proves to be a durable and long-lasting material, rendering it appropriate for pharmaceutical equipment and storage systems. In summary, stainless steel sheets encompass all the necessary characteristics demanded by pharmaceutical applications, thus establishing them as a favored choice within the industry.

- Q: What is the electrical conductivity of stainless steel sheets?

- The electrical conductivity of stainless steel sheets is relatively low compared to other metals, such as copper or aluminum.

Send your message to us

403 cold rolled stainless steel sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords