310s stainless steel sheetsCold rolled/hot rolled

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specifications about stainless steel

Item Name | Stainless steel sheets |

Grade Steel | 201/202/301/304/304L/310S/316/316L/316Ti/321/410/420 |

Technique | old Rolled, Cold Drawn, Hot Rolled |

Brand | TISCO,BAOSTEEL,LISCO,JISCO,ZPSS,POSCO |

Standard | ASTM,AISI,JIS,GB,DIN,EN |

Thickness | 0.3mm-100mm or as your requirement |

Width | 100mm-3000mm or as your requirement |

Length | 1000mm-10000mm or as your requirement |

Surface Treatment | BA,2B,No.1,No.4,No.8,HL,8K,Brush,Mirror,Polish ect |

Packing | 1.Export sea worthy package + water proof paper + wooden pallet 2. Max Loading 26.5mt for each 20Gp container 3.Safe loading and fixing Professiona teams 4. Professional shipping line |

MOQ | 1 TON |

Delivery | 5 days after received the 30% deposit of T/T or L/C |

Payment | T/T,30%payment in advance,70%T/T after the copy of B/L or L/c at sight |

Application | Stainless Steel Sheets are widely used in below fields: 1: Construction field, shipping building industry 2: Petroleum and Chemical Industries 3: Food and Mechanical Industries |

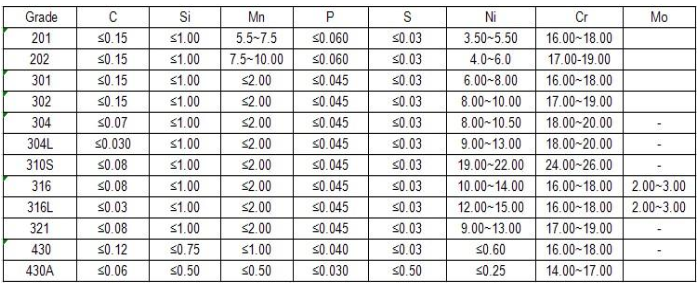

2. Chemical Composition about stainless steel

3. Surface--stainless steel

Surface Finish | Definition | Application |

2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

BA | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

HL | Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size. | Building Construction. |

NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe |

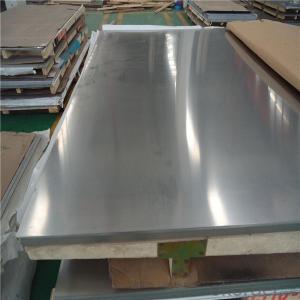

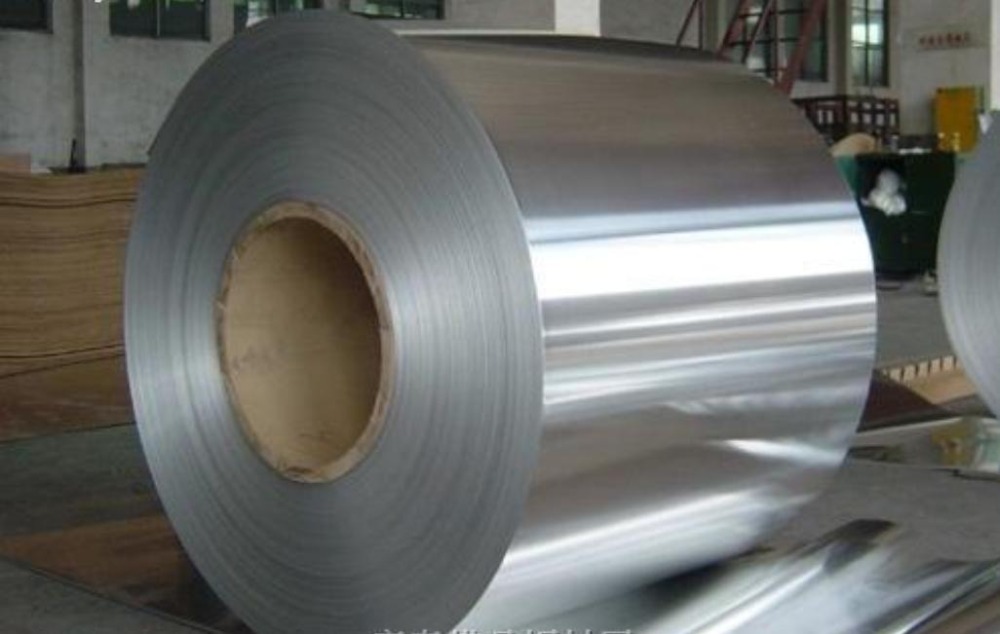

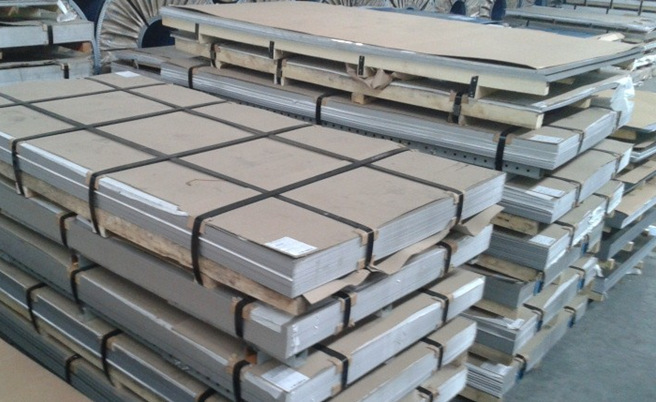

4.Product Photos

Packaging & Shipping

5.Packaging--stainless steel coils

- Q: Can stainless steel sheets be used for brewery tanks?

- Yes, stainless steel sheets can be used for brewery tanks. Stainless steel is a commonly used material in the brewing industry due to its excellent corrosion resistance, strength, and hygienic properties. It is non-reactive, which means it does not interact with the beer or alter its taste, ensuring the purity and quality of the final product. Stainless steel sheets can be formed and welded to create tanks of various shapes and sizes, making them suitable for a wide range of brewing applications. Additionally, stainless steel is easy to clean, maintain, and sanitize, which is vital for maintaining the cleanliness and sterility of brewery tanks. Overall, stainless steel sheets are an ideal choice for brewery tanks due to their durability, chemical resistance, and hygienic properties.

- Q: How are stainless steel sheets installed?

- Different methods are used to install stainless steel sheets depending on the specific application and requirements. Here are several common installation methods for stainless steel sheets: 1. Adhesive: A popular and straightforward method involves using a specialized adhesive to bond the stainless steel sheet to the desired surface. The adhesive is applied to the back of the sheet, which is then firmly pressed onto the surface. This method is suitable for flat or slightly curved surfaces and results in a seamless and clean installation. 2. Mechanical fasteners: When additional strength and stability are necessary, stainless steel sheets can be installed using mechanical fasteners like screws, bolts, or rivets. These fasteners are drilled or screwed through the sheet and into the surface to secure it. This method is often used for installations that require resistance to external forces or for attaching stainless steel sheets to structural components. 3. Welding: In some cases, particularly for large or complex installations, welding may be employed to connect stainless steel sheets together or to other metal structures. Welding creates a strong and permanent bond between the sheets, ensuring a secure installation. However, this method requires skilled professionals and specialized equipment to ensure proper welding techniques and prevent damage to the stainless steel. 4. Magnetic attachment: Certain stainless steel sheets are designed with a magnetic backing, allowing them to be easily attached to magnetic surfaces. This method offers quick and convenient installation as the sheets can be easily repositioned or removed if necessary. However, it is important to ensure that the magnetic surface is clean and free from debris that could affect the adhesion. Before installing stainless steel sheets, it is crucial to thoroughly clean the surface and remove any dirt, dust, or grease. This preparation will help ensure a secure and long-lasting installation. Additionally, following the manufacturer's instructions and guidelines specific to the stainless steel sheet being installed is essential for achieving the best results.

- Q: How do you remove rust from stainless steel sheets?

- To remove rust from stainless steel sheets, there are a few effective methods you can try. Here are a few options: 1. Vinegar: Vinegar is an excellent natural cleaner that can remove rust from stainless steel. Soak a cloth or sponge in white vinegar and rub it onto the rusted areas. Let it sit for a few minutes, then scrub the rust away with a soft-bristle brush. Rinse the sheet with water and dry it thoroughly. 2. Lemon juice and baking soda: Create a paste by mixing lemon juice and baking soda together. Apply the paste to the rusted areas and let it sit for about 10-15 minutes. Scrub the rust away with a soft cloth or sponge, rinse the sheet, and dry it completely. 3. Commercial rust remover: If the rust is stubborn or extensive, you can use a commercial rust remover specifically designed for stainless steel. Follow the instructions on the product and wear protective gloves as some rust removers can be harsh. After applying the rust remover, rinse the sheet thoroughly and dry it well. 4. Sanding or wire brushing: For more severe rust, you can use sandpaper or a wire brush to remove the rust manually. Start with a coarser grit sandpaper or brush and gradually move to a finer grit until the rust is completely removed. Be sure to sand or brush in the direction of the grain to avoid scratching the stainless steel surface. Afterward, clean the sheet with a mild detergent, rinse, and dry thoroughly. Remember to always test any cleaning method or product on a small, inconspicuous area of the stainless steel sheet first to ensure it doesn't cause any damage. Additionally, regular maintenance and proper storage can help prevent future rust formation on stainless steel sheets.

- Q: How do you clean and maintain stainless steel sheets?

- To clean and maintain stainless steel sheets, you'll need a few basic supplies: a microfiber cloth or soft sponge, mild dish soap or stainless steel cleaner, warm water, and a towel for drying. Start by rinsing the stainless steel sheet with warm water to remove any loose dirt or grime. Then, apply a small amount of mild dish soap onto the microfiber cloth or sponge and gently scrub the surface of the stainless steel sheet. Avoid using abrasive materials or harsh chemicals as they can scratch or damage the stainless steel. After cleaning, rinse the sheet thoroughly with warm water to remove any soap residue. To prevent water spots, wipe the surface dry with a clean towel. Make sure to always dry the stainless steel sheet after cleaning to prevent water spots or streaks. If there are stubborn stains or fingerprints that won't come off with soap and water, you can use a stainless steel cleaner specifically designed for this purpose. Follow the instructions on the cleaner and use a soft cloth to apply it to the sheet. Wipe in the direction of the grain to avoid scratching the surface. Rinse thoroughly and dry as mentioned earlier. To maintain the shine and luster of stainless steel sheets, it's important to avoid using abrasive cleaners, scouring pads, or steel wool, as they can damage the surface. Also, be careful not to use cleaners containing bleach or chlorine as they can cause discoloration. Regularly cleaning the stainless steel sheets is essential to prevent buildup of dirt, grease, or other contaminants that can lead to corrosion. A weekly cleaning routine should suffice for most applications, but you may need to clean more frequently in high-traffic or heavily used areas. In summary, cleaning and maintaining stainless steel sheets involves gentle scrubbing with mild dish soap or stainless steel cleaner, rinsing with warm water, and thorough drying. By following these steps and avoiding abrasive materials, your stainless steel sheets will stay clean, shiny, and looking their best for years to come.

- Q: What are the common uses of stainless steel sheets?

- Stainless steel sheets have a wide range of applications due to their unique properties and versatility. Some of the most common uses include: 1. Construction: Stainless steel sheets are extensively used in the construction industry for roofing, cladding, and facades. They offer excellent durability, corrosion resistance, and a modern aesthetic appeal. 2. Automotive: Stainless steel sheets find applications in the automotive industry for manufacturing various components such as exhaust systems, grilles, trims, and decorative elements. Their resistance to heat, corrosion, and impact makes them ideal for these purposes. 3. Kitchen appliances: Stainless steel sheets are commonly used in the manufacturing of kitchen appliances like refrigerators, ovens, dishwashers, and sinks. Their hygienic properties, resistance to stains, and easy maintenance make them a popular choice for these applications. 4. Food processing: Stainless steel sheets are widely used in the food processing industry due to their non-reactive nature and ease of cleaning. They are used for making equipment such as storage tanks, conveyor systems, work surfaces, and food preparation tables. 5. Medical equipment: Stainless steel sheets are crucial in the manufacturing of medical equipment and devices. They are used for surgical instruments, dental tools, implantable devices, and hospital furniture due to their biocompatibility, corrosion resistance, and ease of sterilization. 6. Aerospace: Stainless steel sheets are utilized in the aerospace industry for constructing aircraft components like fuselage frames, engine parts, and landing gear. Their high strength-to-weight ratio, resistance to extreme temperatures, and corrosion resistance make them suitable for these demanding applications. 7. Energy and power generation: Stainless steel sheets are commonly used in power plants, oil refineries, and chemical processing plants for constructing equipment like heat exchangers, boilers, and storage tanks. Their ability to withstand high temperatures, pressure, and corrosive environments is essential in these industries. 8. Decorative purposes: Stainless steel sheets are also used for decorative purposes in architecture and interior design. They can be used to create unique and modern finishes on walls, ceilings, furniture, and decorative panels. Overall, stainless steel sheets are a versatile material used in various industries due to their exceptional properties like corrosion resistance, durability, hygienic properties, and aesthetic appeal.

- Q: Stainless steel plate how to distinguish between good and bad, there are several thick?

- Stainless steel society due to overstocking. According to the length of time due to overstocking and keeping quality, in general there are two types of:It is not a long time due to overstocking, storage and good processing unit holds not only the original quality certificate or copy, and steel or mark on the packaging and taste and clear. For the identification of this stainless steel, it is also possible to check the mark on the steel or package only on the basis of the quality certificate.Another is the backlog of longer time, storage is not perfect, neither quality certificate, steel or packaging on the mark has not obvious or fall off. For the identification of this type of stainless steel, mainly to conduct in-depth investigation and research, to the processing unit to access the original documents. In general, invoices and other original documents are marked with steel etc.. If there is no steel to access local records, then the price data, the price to ascertain no.. This is to determine several effective methods, but often the wrong person. Therefore, it is necessary to master the method of identifying objects.

- Q: What are the applications of stainless steel sheets?

- Stainless steel sheets have a wide range of applications due to their unique properties. They are commonly used in construction for roofing, cladding, and facades as they offer durability, corrosion resistance, and aesthetic appeal. In the automotive industry, stainless steel sheets are utilized for manufacturing various components, including exhaust systems, grilles, and body panels. They are also employed in the food processing and pharmaceutical industries for their hygienic properties. Additionally, stainless steel sheets find applications in kitchen appliances, chemical plants, marine equipment, and medical instruments, among others.

- Q: What is the electrical resistance of stainless steel sheets?

- The electrical resistance of stainless steel sheets can vary depending on several factors, such as the grade of stainless steel, its thickness, and the specific properties of the alloy used. Generally, stainless steel exhibits a relatively high electrical resistance when compared to other metals. This is primarily due to its composition, which includes a significant amount of chromium and other alloying elements that impede the flow of electric current. However, the precise value of electrical resistance can range from a few micro-ohms per square meter to several ohms per square meter, depending on the specific grade and thickness of the stainless steel sheet. Consequently, it is essential to refer to the manufacturer's specifications or conduct specific electrical resistance tests to obtain accurate values for a particular stainless steel sheet.

- Q: Can stainless steel sheets be used for sound insulation?

- Yes, stainless steel sheets can be used for sound insulation to some extent. While stainless steel is not the most effective material for soundproofing, it does have some sound-dampening properties due to its density and ability to reflect sound waves. However, for optimal sound insulation, it is recommended to use specialized soundproofing materials designed specifically for this purpose.

- Q: What are the different types of stainless steel sheets available?

- There are several different types of stainless steel sheets available, including austenitic, ferritic, martensitic, duplex, and precipitation-hardening stainless steel sheets. Each type has its own unique properties and characteristics, making them suitable for various applications in industries such as construction, automotive, and food processing.

Send your message to us

310s stainless steel sheetsCold rolled/hot rolled

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords