409 stainless steel sheetsCold rolled/hot rolled

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Quick Details:

Name: AISI 316/JIS SUS316 Stainless Steel Sheet

Place of Origin:Liaoning,China Brand Name:Dongbei Tegang

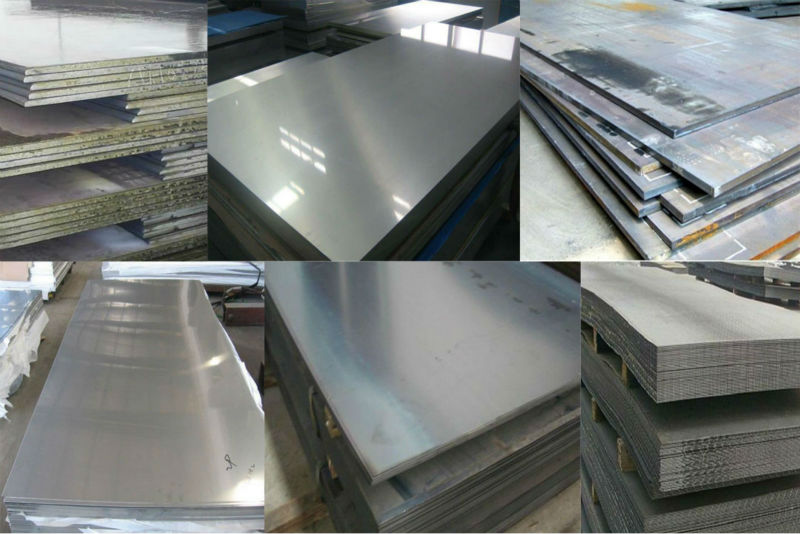

Shape:sheet Material:Stainless Steel

Steel Grade: AISI 316/JIS SUS316/GB 0Cr17Ni12Mo2

Size:Thickness:;width:1m~1.25m;length:2m~2.25m

Application: Engine blade for plane, cartridge receiver, fasterners, combustion chamber, aviation, discs, shaft, outside wall of combustion chamber, liquid oxygen-kerosne diesel, shell, cyclinder, propelling unit, spaceflight, aviation, atomice energy, nuclear energy, petroleum, chemicalsk, marine development.

Chemical composition

C | Si | Mn | P | S | Ni | Cr | Mo |

≤0.08 | ≤1.00 | ≤2.00 | ≤0.035 | ≤0.030 | 10.00~14.00 | 16.00~18.50 | 2.00~3.00 |

Packing&Delivery:

Packaging details: According to customer's require or export's standard

Delivery Time: In 30days after we receive 30% deposite

Port: Dalian

MOQ: 1TON

Standard:

| ASTM | USA | Ameirican Society of Mechanical Engineers |

| AISI | USA | Acronym of American Iron and Steel Institute |

| JIS | JP | Japanese Industrial Standards |

| DIN | GER | Deutsches Institut für Normung e.V. |

| UNS | USA | Unified Numbering System |

Product Advantages:

1,good machining property

2,heat resistant steel

Packaging & Shipping

5.Packaging--stainless steel coils

- Q: What does stainless steel sheet S2 stand for?

- Stainless steel sheet S2 stands for thickness 2mm

- Q: What's the difference between 304 stainless steel and 314?

- 304 stainless steel is a universal stainless steel material: 314 stainless steel; high temperature oxidation resistance and strong mechanical properties; high heat resistant stainless steel, and 314 austenitic stainless steel, high temperature oxidation resistance and creep resistance. 314 stainless steel used in furnace tube difference

- Q: Can stainless steel sheets be used for outdoor furniture or fixtures?

- Yes, stainless steel sheets can be used for outdoor furniture or fixtures. Stainless steel is highly resistant to corrosion, making it a suitable material for outdoor applications. It is durable, weather-resistant, and can withstand harsh environmental conditions. Additionally, stainless steel has an attractive appearance and can be easily cleaned and maintained, making it an ideal choice for outdoor furniture or fixtures.

- Q: How are stainless steel sheets produced?

- Stainless steel sheets are produced through a process called hot rolling, where stainless steel ingots are heated and passed through a series of rollers to reduce their thickness and improve their surface finish. This continuous rolling process creates long sheets of stainless steel, which are then cooled and cut into desired lengths. The sheets may undergo further processing, such as annealing or surface treatment, before being packaged and shipped for various applications.

- Q: What are the different types of embossed patterns available for stainless steel sheets?

- Stainless steel sheets offer a variety of embossed patterns to choose from. Some of the commonly seen options are as follows: 1. Diamond Pattern: This pattern showcases a series of diamond-shaped raised protrusions on the sheet's surface. It is a popular choice as it adds visual interest and texture to various applications. 2. Linen Pattern: The linen pattern features parallel lines that create a textured appearance resembling linen fabric. Architects and interior designers often utilize this pattern due to its unique aesthetic. 3. Squares Pattern: As the name suggests, this design consists of square-shaped raised protrusions on the stainless steel sheet. It provides a clean and modern look, suitable for a wide range of applications. 4. Leather Pattern: The leather pattern imitates the texture and appearance of leather, adding elegance and sophistication to stainless steel sheets. It is a favored choice for decorative purposes. 5. Moire Pattern: The moire pattern creates a wavy or rippled design, resulting in an optical illusion effect. It adds a dynamic visual element to stainless steel sheets, making them stand out. 6. Checkerplate Pattern: This pattern consists of raised squares or rectangles arranged in a checkered pattern. Its high slip resistance makes it ideal for applications where safety is crucial, such as stairs or ramps. These examples represent only a fraction of the embossed patterns available for stainless steel sheets. The choice of pattern depends on aesthetic preference, functionality, and specific application requirements. Whether for architectural, interior design, or industrial purposes, there is a wide range of embossed patterns to cater to various needs.

- Q: Can stainless steel sheets be bent or formed without cracking?

- Yes, stainless steel sheets can be bent or formed without cracking, as they have high ductility and excellent formability properties.

- Q: What is the thermal expansion rate of stainless steel sheets?

- The thermal expansion rate of stainless steel sheets varies based on the specific grade of stainless steel and the temperature range it is exposed to. Typically, stainless steel has a coefficient of thermal expansion (CTE) of approximately 10-17 x 10^-6 per degree Celsius (µm/m°C). This implies that for each degree Celsius rise in temperature, the stainless steel sheet will expand by 10-17 micrometers per meter of length. It is worth noting that the CTE may slightly differ for various grades of stainless steel, so it is advisable to refer to the manufacturer's specifications or engineering handbooks for more accurate information regarding the thermal expansion rate of a particular stainless steel sheet.

- Q: How do you determine the hardness of stainless steel sheets?

- There are multiple methods available to determine the hardness of stainless steel sheets. The Rockwell hardness test is a commonly used method that involves measuring the depth of indentation on the material's surface. This is done by applying a specific load using a diamond cone or steel ball and measuring the resulting depth of penetration. The Rockwell hardness value is then determined based on this depth. Another method is the Vickers hardness test, which involves using a diamond indenter to create a square-shaped indentation. The size of this indentation is measured and converted into a hardness value. This method is often preferred for thin materials like stainless steel sheets. The Brinell hardness test is an alternative technique where a known load is applied to the material using a hardened steel ball. The resulting indentation's diameter is then measured, and the hardness value is calculated based on both the applied load and the diameter of the indentation. Apart from these mechanical tests, non-destructive methods such as ultrasonic hardness testing and magnetic hardness testing can also be employed. Ultrasonic testing determines the speed of sound through the material, which is then correlated to its hardness. Magnetic hardness testing, on the other hand, measures the magnetic properties of the material, which are affected by its hardness. Overall, the hardness of stainless steel sheets can be determined using various methods depending on the specific requirements and characteristics of the material.

- Q: Are stainless steel sheets resistant to hydrogen embrittlement?

- Yes, stainless steel sheets are generally resistant to hydrogen embrittlement due to their high strength and low reactivity with hydrogen gas.

- Q: What are the different types of textured finishes available for stainless steel sheets?

- There are several types of textured finishes available for stainless steel sheets, including brushed, embossed, hammered, linen, and mirror finishes.

Send your message to us

409 stainless steel sheetsCold rolled/hot rolled

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords