4' X 8' Aluminum Sheets for Sale - PVDF-Coated Aluminium Composite Panels - Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

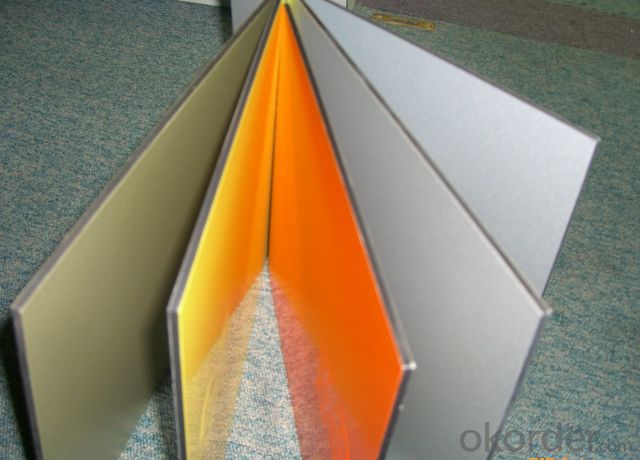

Structure of Aluminium Composite Panels PVDF Description:

PVDF coating aluminium composite panel is composed of a polyethylene core and two aluminium skins. The superb properties of this material boost one’s inspiration and offer architecture a whole new range of solutions, whether your project is a private home, a public building, a corporate headquarter or an office, a trading or industrial complex, or if your organisation wants to create a new image, building Corporate Design, whether for petrol stations, car showrooms, banks or supermarkets.

Main Features of Aluminium Composite Panels PVDF:

A) Light weight,flat surface and high strength

B) Excellent heat insulation ,sound insulation,fire-resistance,acid-resistance,alkali-resistance,weatherproofness and non-resonance

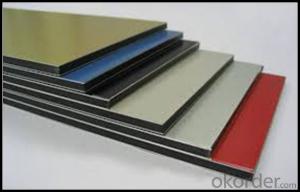

C) Various uniform colors

D) Rbright ,elegan and magnificent,fit for various designs

E) Kynar 5000 PVDF resin feature strong chemical resistance,unique colors can be easily maintained

Images of Aluminium Composite Panels PVDF:

Aluminium Composite Panels Specifications:

Alloy | A1100,A3003,A1050,A8011,A3105,A5005 etc |

Thickness | 0.022mm to 3.0 mm |

Width | Standard width:1240mm; 1200mm |

All width: 30mm - 1600mm | |

Diameter | out dia:1200mm |

Interior dia: 405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE,PVDF,ACRYLIC |

Surface | Embossed, mill finish, coated; aluminum gutter coil |

Color | AS to all RAL color |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ of Aluminium Composite Panels

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 20000㎡.

b. Now which countries do you export your goods?

----Now we export to South East Asia,Africa, North America,South America ect.

- Q: Are the aluminum sheets suitable for aerospace applications?

- Yes, aluminum sheets are suitable for aerospace applications. Aluminum is widely used in the aerospace industry due to its excellent strength-to-weight ratio, corrosion resistance, and high thermal conductivity. These properties make it an ideal material for manufacturing aircraft structures, such as fuselages, wings, and structural components. Additionally, aluminum can be easily machined and formed into complex shapes, allowing for the production of lightweight and aerodynamic structures. Furthermore, aluminum sheets can be easily joined using various techniques, including welding and riveting, ensuring the structural integrity of aerospace components. Overall, aluminum sheets are well-suited for aerospace applications and have been extensively utilized in the industry for many years.

- Q: How do I choose the right thickness for my aluminum sheet?

- When choosing the right thickness for your aluminum sheet, there are several factors you should consider. Firstly, you need to determine the specific application or purpose for which you will be using the aluminum sheet. Different projects may require different thicknesses based on the structural or aesthetic requirements. For instance, if you are using aluminum sheets for roofing or siding, a thicker gauge might be necessary to provide sufficient durability and resistance to weather conditions. Secondly, you should consider the level of strength and rigidity required. Thicker aluminum sheets generally offer greater strength and stability, which is crucial for applications such as construction or automotive components. However, keep in mind that thicker sheets may also be heavier and more difficult to work with, so consider the practicality and weight limitations of your project. Additionally, it is important to think about the size of the aluminum sheet you need. Larger sheets may require thicker gauges to maintain their structural integrity, while smaller sheets may not need as much thickness. Lastly, consider your budget. Thicker aluminum sheets can be more expensive due to the increased material cost and manufacturing process. Strike a balance between the required thickness and your budget constraints to ensure you make a cost-effective decision. In summary, choosing the right thickness for your aluminum sheet involves considering the specific application, required strength, size, and budget. It is recommended to consult with industry experts or suppliers who can provide guidance and advice based on your specific needs.

- Q: Can the aluminum sheets be used for manufacturing ventilation systems?

- Yes, aluminum sheets can be used for manufacturing ventilation systems. Aluminum is a lightweight and durable material that has excellent corrosion resistance properties, making it suitable for ventilation applications. It can be easily formed and fabricated into various shapes and sizes, allowing for the customization of ventilation components. Additionally, aluminum is a good conductor of heat, which can be beneficial for HVAC systems that require efficient heat transfer.

- Q: What are the semi hard ones? What are the alloys? What are the anti rust ones, such as 3003505210606061, 7075?

- Three 3000 series aluminum representing 30033003 3A21. Also known as China's 3000 series aluminum antirust aluminum production process is more outstanding.3000 series aluminum is made of manganese as main components. The contents of 1.0-1.5 in between. Is a series of anti rust function better. Routine application in air conditioning, ice box, car etc. in the moist environment, price more than 1000 series, is a commonly used alloy series.Four 4000 series aluminum on behalf of the 4A01 4000 series aluminum plate belongs to the high silicon content series. Usually silicon content between 4.5-6.0%. Belongs to the building material, mechanical parts, forging materials, welding materials; low melting point, good corrosion resistance of the product description: has the characteristics of heat resistance, wear resistanceFive series of 5000 representative 5052.5005.5083.5A05.5000 series is a commonly used aluminum alloy aluminum series, the main elements of magnesium, magnesium content in 3-5%. Also called aluminum magnesium alloy. The main characteristics of low density, high tensile strength, elongation rate is high. In the same area under the weight of the aluminium magnesium alloy is lower than that of the other series. It is commonly used in aviation, such as aircraft fuel tank. The application in the conventional industries are more widely. The processing technology for slab continuous casting and rolling, which belongs to the aluminum plate series so can do deep processing of aluminum oxidation. More mature system in our country in 5000 series aluminum one.Six series of 6000 representatives of 6061 mainly contains two elements of magnesium and silicon, so the advantages of 4000 series and 5000 Series 6061 is a cold forging processing of aluminum products, suitable for applications in corrosion resistance, oxidation resistance requirement. Use good interface features excellent, easy coating, processing is good. Can be used for low pressure weapons and aircraft joints.

- Q: Are aluminum sheets suitable for reflective signage?

- Yes, aluminum sheets are highly suitable for reflective signage due to their excellent reflective properties. The smooth surface of aluminum ensures high visibility and increased reflectivity, making it an ideal material for creating reflective signage that is easily visible, even in low light conditions.

- Q: Are the aluminum sheets suitable for HVAC (heating, ventilation, and air conditioning) applications?

- Yes, aluminum sheets are suitable for HVAC (heating, ventilation, and air conditioning) applications. Aluminum is a popular choice in the HVAC industry due to its excellent thermal conductivity, corrosion resistance, and lightweight properties. These sheets are commonly used for ductwork, heat exchangers, and air handling units in HVAC systems. Aluminum sheets can efficiently transfer heat and withstand high temperatures, making them ideal for heating applications. Additionally, their resistance to corrosion ensures long-term durability in moist environments, such as air conditioning systems. Moreover, the lightweight nature of aluminum sheets simplifies installation and reduces the overall weight of HVAC equipment. Overall, aluminum sheets are a reliable and versatile material for HVAC applications.

- Q: Is aluminum sheet magnetic?

- No, aluminum sheet is not magnetic.

- Q: What rules or guidelines exist for using recycled aluminum sheets in construction projects?

- <p>Yes, there are regulations and guidelines regarding the use of recycled aluminum sheets in construction. These often include standards for material quality, safety, and environmental impact. The American Society for Testing and Materials (ASTM) and the Aluminum Association provide specifications for recycled aluminum alloys used in construction. Compliance with building codes and local regulations is essential. Additionally, recycled aluminum must meet performance and safety standards equivalent to those of new materials. It's crucial to check with local building authorities and consult the latest industry standards to ensure compliance when using recycled aluminum in construction.</p>

- Q: Are the aluminum sheets suitable for manufacturing architectural column covers?

- Yes, aluminum sheets are suitable for manufacturing architectural column covers. Aluminum is a lightweight yet durable material that offers excellent corrosion resistance, making it ideal for exterior applications such as column covers. It can be easily shaped, bent, and fabricated to create custom designs and sizes, allowing for versatility in architectural projects. Additionally, aluminum sheets can be finished with various coatings, such as powder coating or anodizing, to enhance their aesthetic appeal and provide additional protection against weathering and wear. Overall, aluminum sheets provide a great combination of strength, versatility, and aesthetics, making them a suitable choice for manufacturing architectural column covers.

- Q: How does aluminum sheet perform in outdoor applications?

- Aluminum sheet performs exceptionally well in outdoor applications due to its inherent corrosion resistance and durability. It is highly resistant to rust and can withstand exposure to harsh weather conditions, making it ideal for outdoor structures, signage, and cladding. Additionally, aluminum sheets can be coated or painted to enhance their weather resistance and aesthetic appeal. Overall, aluminum sheet is a reliable and long-lasting material for various outdoor applications.

Send your message to us

4' X 8' Aluminum Sheets for Sale - PVDF-Coated Aluminium Composite Panels - Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords