3M Welded Delivery Pipe for Cifa Concrete Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

3M Welded Delivery Pipe for Cifa Concrete Pump

1. Structure of 3M Welded Delivery Pipe for Cifa Concrete Pump:

St52 Welded Pipe: Main use for Trailer-mounted pump, thickness has 4.0mm, 4.5mm, 5mm. Compare with for Truck-mounted pump. Welded pipe has cheaper price, so it is popular in Saudi, Pakistan, India, etc. Unit Price is about 30USD-33USD.

St52 Seamless Pipe: Now More People like use this kind for Truck Pump and Trailer Pump because of the quality is better and it is seamless kind, so this kind pipe is most popular in Middle East Price About 34USD-37USD.

Wear Resistant Pipe: Use for Truck Pump, Wear Resistant Layer is 2.5mm.Through heat treatment way make this pipe more strong (HRC60-62), Using Life: 25,000m³-35,000m³ Price about 65USD-68USD.

2. Main Features of 3M Welded Delivery Pipe for Cifa Concrete Pump:

• High Wear-resistant, long service life, lower cost

• In case of quality problem the company provide free replacement.

• Provide consumers with regular visits

• Our company passed the ISO9000 certification, the product through 3C certification in full compliance with national standards

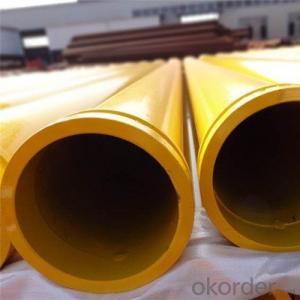

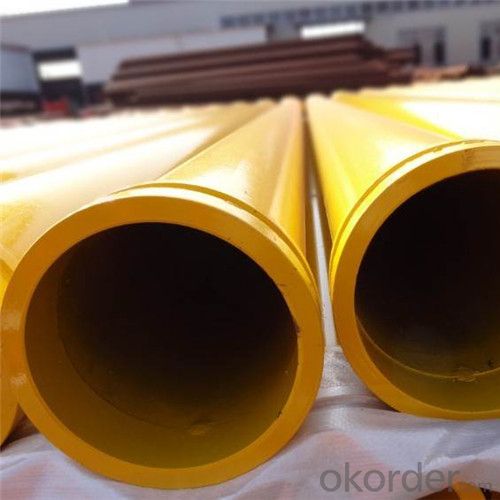

3. 3M Welded Delivery Pipe for Cifa Concrete Pump Images

4. 3M Welded Delivery Pipe for Cifa Concrete Pump Specification

Production Process

5. FAQ

We have organized several common questions for our clients, may help you sincerely:

①Is your products exported a lot?

We have exported to many, many countries. Every year we ship more than 30 containers of these spare parts. Our main market is in Middle-east, Asia & Africa.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 15 working days can be served.

6. Why choose us

• We have been specialized in producing concrete pump spare parts and specialized in producing all kinds of concrete pump parts. As Concrete Pump Pipe, Concrete Pump Elbow, Concrete Pump Rubber Hose, Concrete Pump Wear Plate, Concrete Pump S Valve, Concrete Pump Piston and so on.

• We are famous for our superior quality, competitive prices, first-class craftworks, safe package and prompt delivery.

• We have been supplying concrete pump parts for SCHWING, PUTZMEISTER, SANY, CIFA, KYOKUTO, ZOOMLION for 10 years, so we can promise you the quality and best price.

- Q: Can concrete pump spare parts be coated with anti-corrosion or anti-wear coatings?

- Yes, concrete pump spare parts can be coated with anti-corrosion or anti-wear coatings. These coatings help protect the parts from the corrosive nature of concrete or the wear and tear caused by continuous pumping. The coatings can extend the lifespan of the spare parts and improve their performance and durability.

- Q: What are the signs of a damaged concrete pump accumulator?

- There are several signs that indicate a damaged concrete pump accumulator. One of the most common signs is a decrease in the pumping efficiency. If you notice that the concrete pump is not able to pump the concrete as effectively as it used to, it could be a sign of a damaged accumulator. Another sign is a decrease in the pressure of the concrete being pumped. If you notice that the pressure is not as strong as before, or if there are sudden drops in pressure during pumping, it could indicate a problem with the accumulator. Leaks around the accumulator are also indicative of damage. If you notice any fluid leaks around the accumulator, it could mean that the accumulator is damaged or the seals are worn out. This can result in a loss of pressure and inefficiency in pumping. Unusual noises coming from the concrete pump can also be a sign of a damaged accumulator. If you hear any strange noises, such as knocking or hissing sounds, it could be a result of a damaged accumulator. Lastly, if you observe any visible damage on the accumulator itself, such as cracks or dents, it is a clear sign of damage. These damages can compromise the integrity of the accumulator and affect its performance. In summary, signs of a damaged concrete pump accumulator include decreased pumping efficiency, decreased pressure, leaks, unusual noises, and visible damages. If you notice any of these signs, it is important to address the issue promptly to prevent further damage and ensure the smooth operation of the concrete pump.

- Q: How often should concrete pump accumulators be inspected and replaced?

- Concrete pump accumulators should be inspected at least once a year to ensure their proper functioning and identify any potential issues. However, the frequency of replacement depends on various factors such as usage, maintenance, and the manufacturer's recommendations. It is recommended to consult the equipment manual or contact the manufacturer for specific guidelines on replacement intervals.

- Q: Can I get spare parts for both concrete pumps with and without agitators?

- Yes, you can get spare parts for both types of concrete pumps - those with agitators and those without. Many manufacturers and suppliers of concrete pumps offer a wide range of spare parts to ensure the smooth operation and maintenance of these machines. These spare parts include but are not limited to wear plates, cutting rings, delivery cylinders, pistons, seals, hoses, valves, and filters. It is recommended to contact the manufacturer or authorized dealers of the specific concrete pump brand you are using to inquire about the availability and pricing of spare parts for both types of pumps.

- Q: How does a concrete pump S valve function?

- A concrete pump S valve functions by controlling the flow of concrete from the hopper to the delivery pipeline. It consists of two flat plates attached to a shaft that can rotate. When the S valve is in the closed position, the plates are pressed together to prevent the concrete from flowing through. As the shaft rotates, the plates separate, allowing the concrete to pass through and be pumped to the desired location. This mechanism ensures efficient and precise control of concrete flow during pumping operations.

- Q: How often should concrete pump remote controls be inspected and maintained?

- To ensure proper functioning and prevent any potential issues, it is important to regularly inspect and maintain concrete pump remote controls. The frequency of inspections and maintenance depends on factors such as usage intensity, environmental conditions, and manufacturer recommendations. As a general rule, it is recommended to inspect and maintain concrete pump remote controls once every three months. During these inspections, check for visible damage, loose or worn-out parts, and ensure that all buttons and switches are working correctly. Additionally, inspect and clean the battery compartment, and replace batteries if needed. However, in situations where there is high demand or extreme environmental conditions, more frequent inspections and maintenance may be necessary. For example, if the concrete pump is used in a harsh environment with excessive dust or moisture, it is advisable to increase the frequency of inspections and cleanings to prevent damage or malfunction. Following the manufacturer's guidelines and recommendations for maintenance is crucial. They may provide specific instructions on lubrication, calibration, or other maintenance procedures that should be carried out regularly. By adhering to these guidelines, concrete pump remote controls can be kept in optimal condition, ensuring safe and efficient operation.

- Q: How often should concrete pump hydraulic motors be inspected and replaced?

- Concrete pump hydraulic motors should be inspected regularly, ideally every 500 to 1000 hours of operation, to ensure they are in good working condition. However, the frequency of replacement depends on various factors such as usage intensity, maintenance practices, and the quality of the motor. Generally, hydraulic motors can last for several years if properly maintained, but if any signs of wear, leakage, or reduced performance are observed, it is recommended to replace them promptly to prevent potential breakdowns or accidents.

- Q: How often should hopper cylinder seals be replaced in a concrete pump?

- The replacement frequency of hopper cylinder seals in a concrete pump varies depending on factors such as seal quality, usage intensity, and maintenance practices. It is recommended to regularly inspect hopper cylinder seals for any signs of wear or damage, and if cracks, tears, or leaks are visible, immediate replacement is advised to prevent further damage to the concrete pump. In general, hopper cylinder seals can last for several months to a couple of years, depending on the aforementioned factors. However, it is crucial to establish a preventive maintenance plan and regularly monitor the seals' condition to ensure optimal performance and minimize downtime. Furthermore, consulting the manufacturer's guidelines or seeking advice from a professional concrete pump technician is advisable to determine the specific replacement interval for hopper cylinder seals based on the pump model, usage patterns, and environmental conditions.

- Q: What are the safety measures to consider while replacing concrete pump spare parts?

- When replacing concrete pump spare parts, there are several safety measures that should be considered to ensure the safety of the workers and the overall success of the replacement process. 1. Lockout/Tagout: Before starting any maintenance or replacement work, it is crucial to follow proper lockout/tagout procedures. This involves isolating the equipment from its power source and placing lockout devices to prevent accidental startup. This ensures that the equipment cannot be operated while replacement work is being carried out. 2. Personal Protective Equipment (PPE): Workers involved in the replacement process should wear appropriate PPE such as safety goggles, gloves, hard hats, and steel-toed boots. This protects them from potential hazards like flying debris, falling objects, or accidental contact with sharp edges. 3. Equipment Inspection: Before commencing the replacement, the equipment should be thoroughly inspected to identify any potential hazards or defects. This includes checking for damaged or worn-out parts, loose connections, or any signs of deterioration. If any issues are found, they should be resolved or repaired before proceeding with the replacement. 4. Proper Lifting Techniques: Concrete pump spare parts can be heavy and bulky, so it is essential to use proper lifting techniques to prevent musculoskeletal injuries. Workers should be trained on lifting techniques and should use mechanical aids like cranes, hoists, or forklifts when necessary. Additionally, team lifting should be employed when dealing with heavy or awkwardly shaped parts. 5. Secure Work Area: The work area should be properly secured to prevent unauthorized access and ensure the safety of workers. Barricades or caution tape can be used to cordon off the area and warn others of the ongoing replacement work. Adequate lighting should also be provided to ensure clear visibility. 6. Proper Tools and Equipment: Using the right tools and equipment is crucial for safe and efficient replacement work. Workers should be trained on the proper use of tools and ensure that they are in good working condition. Using damaged or faulty tools can lead to accidents or improper installation of the spare parts. 7. Follow Manufacturer's Instructions: It is important to follow the manufacturer's instructions and guidelines for replacing concrete pump spare parts. This includes understanding the correct sequence of steps, torque requirements, and any special precautions that need to be taken. Deviating from the manufacturer's instructions can compromise the safety and performance of the equipment. By following these safety measures, the risk of accidents, injuries, or equipment damage can be minimized during the replacement of concrete pump spare parts. It is crucial to prioritize safety at all times and ensure that all workers involved are properly trained and equipped to carry out the replacement work.

- Q: What is the purpose of a concrete pump cleaning ball?

- To effectively cleanse and eliminate any lingering concrete or debris inside a concrete pump system, a concrete pump cleaning ball serves its purpose. These cleaning balls are specifically designed for insertion into the pumping system and subsequent propulsion through the pipes using water pressure or compressed air. As they progress through the system, the cleaning balls effectively scrape away any solidified concrete or accumulation, guaranteeing unobstructed flow and optimal performance of the pump and pipes. This routine cleaning process not only prevents blockages and upholds pump efficiency but also prolongs the equipment's lifespan. Furthermore, the utilization of cleaning balls ensures that the subsequent batch of pumped concrete remains uncontaminated by any residual debris, resulting in a superior final product.

Send your message to us

3M Welded Delivery Pipe for Cifa Concrete Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords