3M Welded Delivery Pipe for Putzmeister Concrete Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

3M Welded Delivery Pipe for Putzmeister Concrete Pump

1. Structure of 3M Welded Delivery Pipe for Putzmeister Concrete Pump:

St52 Weld Pipe: Main use for Trailer-mounted pump, thickness has 4.0mm, 4.5mm, 5mm. Compare with for Truck-mounted pump. Weld pipe has cheaper price, so it is popular in Saudi, Pakistan, India, etc. Unit Price is about 30USD-33USD.

St52 Seamless Pipe: Now More People like use this kind for Truck Pump and Trailer Pump because of the quality is better and it is seamless kind, so this kind pipe is most popular in Middle East Price About 34USD-37USD.

Wear Resistant Pipe: Use for Truck Pump, Wear Resistant Layer is 2.5mm.Through heat treatment way make this pipe more strong (HRC60-62), Using Life: 25,000m³-35,000m³ Price about 65USD-68USD.

Two Wall Pipe: This pipe thickness (2mm+2.5mm), Using Life about 50,000m³-60,000m³

2. Main Features of 3M Welded Delivery Pipe for Putzmeister Concrete Pump:

• High Wear-resistant, long service life, lower cost

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Provide consumers with regular visits

• Ensure the supply of ancillary parts

• Our company passed the ISO9000 certification, the product through 3C certification in full compliance with national standards

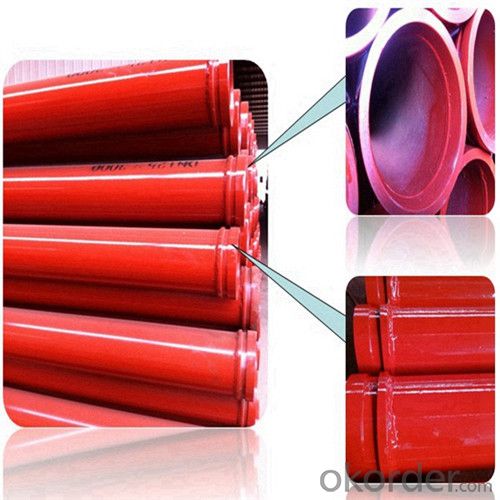

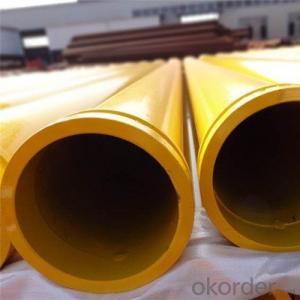

3. 3M Welded Delivery Pipe for Putzmeister Concrete Pump Images

4. 3M Welded Delivery Pipe for Putzmeister Concrete Pump Specification

Production Process

5. FAQ

We have organized several common questions for our clients, may help you sincerely:

①Is your products exported a lot?

We have exported to many, many countries. Every year we ship more than 30 containers of these spare parts. Our main market is in Middle-east, Asia & Africa.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 15 working days can be served.

6. Why choose us

• We are a comprehensive manufacturing and trading company.

• Our company is one of the biggest manufacturing and trading companies in China.

• We have been specialized in producing concrete pump spare parts and specialized in producing all kinds of concrete pump parts. As Concrete Pump Pipe, Concrete Pump Elbow, Concrete Pump Rubber Hose, Concrete Pump Wear Plate, Concrete Pump S Valve, Concrete Pump Piston and so on.

• We are famous for our superior quality, competitive prices, first-class craftworks, safe package and prompt delivery.

• We have been supplying concrete pump parts for SCHWING, PUTZMEISTER, SANY, CIFA, KYOKUTO, ZOOMLION for 10 years, so we can promise you the quality and best price.

- Q: Are there any maintenance tips to extend the lifespan of concrete pump spare parts?

- Yes, there are several maintenance tips to extend the lifespan of concrete pump spare parts. Regular cleaning and lubrication of the parts, proper storage to prevent corrosion, and routine inspection for wear and tear are essential. Additionally, using high-quality spare parts and following manufacturer's guidelines for maintenance and operation can significantly increase their longevity.

- Q: How can one identify the correct part number for a specific concrete pump spare part?

- To identify the correct part number for a specific concrete pump spare part, there are a few steps you can follow: 1. Check the equipment manual: The first place to look is the manual that came with the concrete pump. It should provide a detailed parts list along with their corresponding part numbers. This is the most reliable and accurate source of information. 2. Contact the manufacturer: If you don't have access to the equipment manual or if it doesn't provide the necessary information, reach out to the manufacturer directly. They should be able to assist you in identifying the correct part number for the specific concrete pump spare part you need. Provide them with as much information as possible, such as the make, model, and serial number of the concrete pump. 3. Use online resources: There are various online platforms and parts catalogs available that provide detailed information about spare parts for different concrete pump brands and models. These resources often allow you to search for the part based on the make and model of your concrete pump. Make sure to cross-reference the information you find with the manufacturer's specifications to ensure accuracy. 4. Consult with a local dealer or distributor: If you are unable to find the correct part number through the above methods, consider reaching out to a local dealer or distributor of concrete pump spare parts. They often have extensive knowledge and experience in identifying and sourcing the right parts for different equipment. Provide them with all the necessary details about your concrete pump, and they should be able to assist you in finding the correct part number. Remember, accuracy is crucial when identifying the correct part number for a specific concrete pump spare part. Using reliable sources and consulting with professionals will help ensure that you obtain the right part for your equipment's needs.

- Q: How can a damaged concrete pump hopper affect the pumping process?

- A damaged concrete pump hopper can have several negative impacts on the pumping process. Firstly, a damaged hopper can lead to a decrease in efficiency and productivity. The hopper is responsible for holding and feeding the concrete mixture into the pump, and any damage to it can result in a disruption of the continuous flow of concrete. This can lead to frequent interruptions in the pumping process, causing delays and reducing the overall output of the pump. Secondly, a damaged hopper can affect the quality of the concrete being pumped. The hopper is designed to ensure proper mixing and consistency of the concrete mixture before it is pumped. If the hopper is damaged, it may not be able to effectively mix the concrete, leading to inconsistencies in the mixture. This can result in poor-quality concrete being pumped, which can compromise the structural integrity and durability of the final product. Moreover, a damaged hopper can pose safety risks for the workers involved in the pumping process. A damaged hopper may have sharp edges or loose parts that can cause injury if not properly addressed. Additionally, if the hopper is not functioning properly, it may lead to clogs or blockages in the pump, which can cause pressure build-up and potential accidents. Lastly, a damaged hopper can increase maintenance and repair costs. A hopper that is not in optimal condition may require frequent repairs or even replacement, which can be costly in terms of time and money. Regular maintenance and inspection of the hopper is crucial to identify any damages early on and prevent them from escalating into more significant issues. In conclusion, a damaged concrete pump hopper can significantly affect the pumping process by reducing efficiency, compromising the quality of the concrete, posing safety risks, and increasing maintenance costs. Regular inspection, maintenance, and timely repairs are essential to ensure the smooth operation of the pump and the delivery of high-quality concrete.

- Q: How do I ensure the compatibility of mechanical components in concrete pump spare parts?

- To guarantee the compatibility of mechanical components in concrete pump spare parts, there are several essential measures you can take: 1. Determine the exact make and model of your concrete pump: Different concrete pumps may have different designs and specifications, so it is crucial to identify the specific make and model of your pump. This information will assist you in selecting the appropriate spare parts for your particular pump. 2. Review the manufacturer's documentation: Examine the manufacturer's documentation, which includes the user manual and parts catalog, to understand the recommended spare parts for your concrete pump. These documents typically provide detailed information on the compatibility of various mechanical components. 3. Seek guidance from the manufacturer or authorized dealers: If you have doubts about the compatibility of certain mechanical components, it is advisable to consult the manufacturer or authorized dealers. They possess extensive knowledge and experience with their products and can offer advice on choosing compatible spare parts. 4. Consider utilizing OEM (Original Equipment Manufacturer) parts: OEM parts are specifically designed and manufactured by the original equipment manufacturer. Employing OEM parts ensures the highest level of compatibility and reliability. Although they may be slightly more expensive than aftermarket alternatives, they often provide superior performance and longer service life. 5. Verify standardized sizing and specifications: Mechanical components, such as seals, gaskets, and bearings, frequently adhere to standardized sizes and specifications. Ensure that the spare parts you are considering match these standardized measurements to guarantee compatibility. 6. Conduct thorough research and comparison: Prior to purchasing spare parts, conduct research on various suppliers and compare their offerings. Look for reputable suppliers who specialize in concrete pump spare parts and have a proven track record of delivering high-quality, compatible components. 7. Perform compatibility testing: If you are unsure about the compatibility of a specific mechanical component, consider conducting compatibility tests. This may involve installing the spare part in your concrete pump and assessing its fit, function, and performance. If possible, seek assistance from a qualified mechanic or technician to assist you with these tests. By following these steps, you can ensure the compatibility of mechanical components in concrete pump spare parts, minimizing the risk of compatibility issues and ensuring the smooth operation and maintenance of your concrete pump.

- Q: What are the potential risks associated with the installation and replacement of concrete pump spare parts?

- The installation and replacement of concrete pump spare parts come with various potential risks. Improper installation is a key risk, as it can cause leaks, reduced performance, and even equipment failure. This not only leads to expensive repairs but also poses a safety threat to workers and those nearby. Another risk is the use of counterfeit or low-quality spare parts. These parts may not meet the necessary standards, compromising the integrity and functionality of the concrete pump. This increases the likelihood of equipment failure and accidents. Moreover, the installation and replacement process may involve operating heavy machinery like cranes or forklifts, which can be dangerous if not done correctly. Inadequate precautions can result in accidents, injuries, or damage to the equipment or surrounding structures. Additionally, concrete pump spare parts may contain hazardous materials or substances. Workers must be aware of the risks associated with handling and disposing of these materials, such as exposure to harmful chemicals or environmental contamination. Lastly, there is a risk of delays and downtime during the installation and replacement process. If spare parts are not readily available or compatibility issues arise, equipment may be inoperable for extended periods. This can cause project delays, increased costs, and potential financial losses. To mitigate these risks, it is crucial to provide proper training and supervision to workers involved in the installation and replacement of concrete pump spare parts. Using genuine and high-quality spare parts from reputable suppliers can also reduce the risk of equipment failure. Regular inspections, maintenance, and adherence to safety protocols are essential to minimize potential risks associated with this process.

- Q: How often should concrete pump water pumps be inspected and replaced?

- The frequency of inspection and replacement for concrete pump water pumps depends on several factors including the workload, operating conditions, and maintenance practices. Generally, it is recommended to inspect the water pump at least once a month to ensure its proper functioning. During the inspection, it is important to check for any leaks, unusual noises, or signs of wear and tear. If any issues are identified, immediate action should be taken to resolve them, such as repairing or replacing damaged parts. As for replacement, it is difficult to provide an exact timeframe as it varies depending on the quality of the pump, the intensity of use, and the level of maintenance. However, a general guideline is to consider replacing the water pump every 1-2 years for heavy usage or every 3-5 years for moderate usage. Regular maintenance, such as cleaning and lubricating the pump, can extend its lifespan and minimize the need for frequent replacements. It is important to note that these recommendations are general guidelines and may vary depending on the specific manufacturer's instructions, industry standards, and local regulations. It is advisable to consult the manufacturer's guidelines and seek professional advice from experts in the field to determine the appropriate inspection and replacement schedule for concrete pump water pumps in your specific circumstances.

- Q: How do concrete pump spare parts contribute to the overall performance of the pump?

- Concrete pump spare parts play a crucial role in enhancing the overall performance of the pump. These spare parts are specifically designed to withstand the harsh and demanding conditions of pumping concrete, ensuring the efficiency and longevity of the pump. One of the key contributions of concrete pump spare parts to the overall performance of the pump is their ability to enhance the pumping capacity and efficiency. These spare parts, such as the pump cylinders, pistons, and valves, are designed to provide a smooth and consistent flow of concrete without any interruptions. By maintaining a steady flow, these spare parts help to maximize the pumping capacity of the pump, enabling it to handle larger volumes of concrete in a shorter amount of time. Moreover, concrete pump spare parts also contribute to the overall performance of the pump by improving its durability and reliability. The spare parts are made from high-quality materials, such as hardened steel and wear-resistant alloys, which are specifically chosen to withstand the abrasive nature of concrete. This ensures that the pump can operate continuously without experiencing premature wear or failure. In addition, the proper functioning of concrete pump spare parts also ensures the safety of the pump operators and the surrounding environment. For instance, the wear plates and cutting rings help to prevent concrete leakage, reducing the risk of accidents and environmental contamination. Similarly, the seals and gaskets ensure a tight and secure connection between different components, preventing any potential leaks or malfunctions. Furthermore, concrete pump spare parts also contribute to the overall performance of the pump by reducing downtime and maintenance costs. As these spare parts are subjected to wear and tear during operation, they are designed to be easily replaceable. This allows for quick and efficient repair or replacement of damaged parts, minimizing the downtime of the pump. Additionally, by using genuine and high-quality spare parts, the need for frequent repairs and maintenance is reduced, resulting in lower overall maintenance costs. In conclusion, concrete pump spare parts are essential components that significantly contribute to the overall performance of the pump. They enhance the pumping capacity, durability, and reliability of the pump, ensuring a smooth and efficient operation. Moreover, these spare parts also promote safety, reduce downtime, and minimize maintenance costs, making them indispensable for the optimal performance of concrete pumps.

- Q: What are the advantages of using ceramic components in concrete pump spare parts?

- Using ceramic components in concrete pump spare parts offers several advantages. Firstly, ceramic materials are renowned for their exceptional durability and resistance to wear. Given the high pressure and intense forces that concrete pumps operate under, it is crucial to have components that can withstand such conditions. Ceramic parts possess superior hardness and strength, making them highly resistant to wear and extending the lifespan of spare parts. Secondly, ceramic components boast excellent corrosion resistance. Concrete consists of various chemicals and substances that can corrode metals. By utilizing ceramic parts, the risk of corrosion is significantly reduced, ensuring the longevity and reliability of the concrete pump spare parts. Furthermore, ceramic materials exhibit low friction coefficients. Consequently, when ceramic components are incorporated into concrete pumps, there is less friction between moving parts. This results in reduced energy consumption and increased efficiency. Ultimately, this can lead to cost savings and improved overall performance of the concrete pump. Moreover, ceramic parts possess high thermal resistance. Concrete pumps generate substantial heat during operation, which can potentially damage or deform certain components. However, ceramic materials can withstand high temperatures without compromising their structural integrity. This ensures the reliability and safety of the concrete pump. Lastly, ceramic components demonstrate excellent dimensional stability. They are less susceptible to expansion or contraction caused by temperature changes. This feature guarantees that spare parts maintain their shape and fit precisely within the concrete pump. Consequently, this precision fitting helps minimize leakage and maintain the pump's efficiency. In summary, the utilization of ceramic components in concrete pump spare parts offers exceptional durability, corrosion resistance, low friction, high thermal resistance, and dimensional stability. These advantages contribute to an increased lifespan, improved performance, reduced maintenance costs, and enhanced overall efficiency of the concrete pump.

- Q: What is the second generation pumping technology of concrete pump?

- The whole hydraulic control technology delivery pump has no constant pressure pump, no PLC in the control box, no nitrogen gas storage tank and no close switch at the water tank. The structure is simple, and the maintenance cost is greatly reduced.

- Q: What are the common causes of overheating in concrete pump spare parts?

- The common causes of overheating in concrete pump spare parts can be attributed to factors such as high ambient temperatures, inadequate lubrication, excessive load or pressure, worn-out or damaged components, and insufficient cooling systems.

Send your message to us

3M Welded Delivery Pipe for Putzmeister Concrete Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords