3M Welded Delivery Pipe for Schwing Concrete Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

3M Welded Delivery Pipe for Schwing Concrete Pump

1. Structure of 3M Welded Delivery Pipe for Schwing Concrete Pump:

St52 Weld Pipe: Main use for Trailer-mounted pump, thickness has 4.0mm, 4.5mm, 5mm. Compare with for Truck-mounted pump. Weld pipe has cheaper price, so it is popular in Saudi, Pakistan, India, etc. Unit Price is about 30USD-33USD.

St52 Seamless Pipe: Now More People like use this kind for Truck Pump and Trailer Pump because of the quality is better and it is seamless kind, so this kind pipe is most popular in Middle East Price About 34USD-37USD.

Wear Resistant Pipe: Use for Truck Pump, Wear Resistant Layer is 2.5mm.Through heat treatment way make this pipe more strong (HRC60-62), Using Life: 25,000m³-35,000m³ Price about 65USD-68USD.

Two Wall Pipe: This pipe thickness (2mm+2.5mm), Using Life about 50,000m³-60,000m³

2. Main Features of 3M Welded Delivery Pipe for Schwing Concrete Pump:

• High Wear-resistant, long service life, lower cost

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Provide consumers with regular visits

• Ensure the supply of ancillary parts

• Our company passed the ISO9000 certification, the product through 3C certification in full compliance with national standards

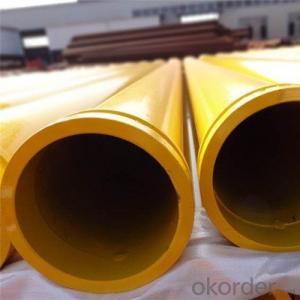

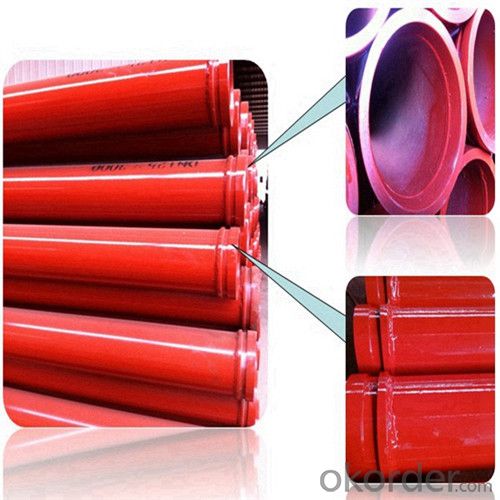

3. 3M Welded Delivery Pipe for Schwing Concrete Pump Images

4. 3M Welded Delivery Pipe for Schwing Concrete Pump Specification

Production Process

5. FAQ

We have organized several common questions for our clients, may help you sincerely:

①Is your products exported a lot?

We have exported to many, many countries. Every year we ship more than 30 containers of these spare parts. Our main market is in Middle-east, Asia & Africa.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 15 working days can be served.

6. Why choose us

• We are a comprehensive manufacturing and trading company.

• Our company is one of the biggest manufacturing and trading companies in China.

• We have been specialized in producing concrete pump spare parts and specialized in producing all kinds of concrete pump parts. As Concrete Pump Pipe, Concrete Pump Elbow, Concrete Pump Rubber Hose, Concrete Pump Wear Plate, Concrete Pump S Valve, Concrete Pump Piston and so on.

• We are famous for our superior quality, competitive prices, first-class craftworks, safe package and prompt delivery.

• We have been supplying concrete pump parts for SCHWING, PUTZMEISTER, SANY, CIFA, KYOKUTO, ZOOMLION for 10 years, so we can promise you the quality and best price.

- Q: What are the different types of concrete pump hopper agitator shaft seals?

- There are various types of concrete pump hopper agitator shaft seals, including packing seals, mechanical seals, and lip seals.

- Q: How often do I need to replace concrete pump spare parts?

- The frequency of replacing spare parts for concrete pumps depends on several factors, such as the quality of the parts, how often the pump is used, and the maintenance practices followed. In general, if you use high-quality spare parts, they can last longer and won't need to be replaced as often. However, if the pump is used extensively or in harsh conditions, the spare parts may wear out more quickly. To ensure that your concrete pump performs well and lasts a long time, it's important to stick to a regular maintenance schedule. This includes checking the spare parts for any signs of damage, monitoring their performance, and replacing them when necessary. It's a good idea to consult the manufacturer's guidelines or get professional advice to determine how often you should replace the spare parts for your concrete pump. Remember, if you neglect proper maintenance or use low-quality spare parts, you may need to replace them more frequently, which can be expensive and disrupt your construction projects. So, it's worth investing in high-quality spare parts and following a diligent maintenance routine to maximize the lifespan of your concrete pump and minimize the need for replacements.

- Q: What are the different types of concrete pump hopper cylinders seals?

- There are several different types of concrete pump hopper cylinder seals, including piston seals, rod seals, wiper seals, and buffer seals.

- Q: What are the advantages of using carbon fiber components in concrete pump spare parts?

- There are several advantages of using carbon fiber components in concrete pump spare parts. Firstly, carbon fiber is known for its high strength-to-weight ratio. This means that carbon fiber components can provide the same strength as traditional materials such as steel or aluminum but with significantly less weight. This results in lighter spare parts, making them easier to handle and install, and also reducing the overall weight of the concrete pump system. Secondly, carbon fiber is highly resistant to corrosion. Unlike steel, carbon fiber does not rust or corrode when exposed to moisture or chemicals. This makes carbon fiber components ideal for use in concrete pump spare parts, as they are constantly exposed to water, cement, and other corrosive substances. The corrosion resistance of carbon fiber ensures the longevity and durability of the spare parts, reducing the need for frequent replacements and maintenance. Another advantage of carbon fiber components is their high stiffness. Carbon fiber is known for its rigidity and low flexural deformation, which means that the spare parts made from carbon fiber will have minimal deflection under load. This stiffness helps to maintain the overall stability and performance of the concrete pump system, ensuring accurate and efficient pumping of concrete. Additionally, carbon fiber has excellent fatigue resistance. Concrete pump spare parts are subjected to continuous cyclic loading and unloading, which can lead to fatigue failure over time. However, carbon fiber components have the ability to withstand these cyclic loads without compromising their structural integrity. This improves the reliability and lifespan of the spare parts, reducing downtime and maintenance costs. Lastly, carbon fiber offers design flexibility. It can be easily molded into complex shapes and geometries, allowing for customized spare parts that can be tailored to specific requirements. This flexibility in design enables the optimization of the spare parts' performance, enhancing the overall efficiency and productivity of the concrete pump system. In conclusion, the advantages of using carbon fiber components in concrete pump spare parts include their high strength-to-weight ratio, corrosion resistance, stiffness, fatigue resistance, and design flexibility. These qualities contribute to the improved performance, durability, and cost-effectiveness of the concrete pump system.

- Q: How can one determine the correct viscosity and temperature range for lubricants used in concrete pump spare parts?

- To determine the correct viscosity and temperature range for lubricants used in concrete pump spare parts, one can refer to the manufacturer's recommendations and specifications. These guidelines will outline the appropriate viscosity grade and temperature range for optimal performance and longevity of the spare parts. It is important to follow these recommendations to ensure efficient lubrication and protection of the concrete pump components. Additionally, consulting with industry experts or conducting research on lubrication requirements specific to concrete pump spare parts can also provide valuable insights for determining the correct viscosity and temperature range.

- Q: How can a faulty concrete pump cylinder affect the pumping process?

- A faulty concrete pump cylinder can have a significant impact on the pumping process. The cylinder plays a crucial role in the concrete pumping system as it is responsible for generating the necessary pressure to push the concrete through the pipes and hoses. One of the main issues caused by a faulty cylinder is a decrease in pumping efficiency. If the cylinder is worn out or damaged, it may not be able to generate sufficient pressure to push the concrete effectively. This can lead to a decrease in the pumping rate and overall productivity of the concrete pumping operation. Furthermore, a faulty cylinder can result in irregular and inconsistent flow of concrete. This can cause blockages or clogs in the pipes, leading to disruptions in the pumping process. These blockages can be time-consuming and costly to remove, as they may require the disassembly of the pumping system to access and clear the blocked area. In addition, a faulty cylinder can cause leaks in the pumping system. These leaks not only waste concrete but also reduce the overall pressure in the system, affecting the ability to pump the concrete to the desired location. Leaks can also lead to a messy worksite, posing safety risks for workers and potentially damaging surrounding structures. Moreover, a faulty cylinder can increase the risk of equipment failure. If the cylinder malfunctions or fails completely, it can cause the entire pumping system to shut down. This can result in significant downtime and delays in the concrete pouring process, leading to additional costs and potential penalties. Overall, a faulty concrete pump cylinder can greatly affect the pumping process by decreasing pumping efficiency, causing irregular flow, promoting leaks, and increasing the risk of equipment failure. Regular maintenance, inspection, and timely replacement of the cylinder are essential to ensure smooth and efficient concrete pumping operations.

- Q: How do I properly maintain and replace hydraulic motors in concrete pump spare parts?

- Proper maintenance and replacement of hydraulic motors in concrete pump spare parts involves several key steps. Firstly, it is crucial to regularly inspect and clean the motors to remove any dirt, debris, or build-up that may affect their performance. Additionally, checking and topping up the hydraulic fluid levels is essential to ensure optimal operation. Regularly monitoring the motors for any signs of leaks, unusual noises, or decreased efficiency is also important. If any issues are detected, prompt repairs or replacements should be undertaken by experienced professionals to prevent further damage. It is recommended to follow the manufacturer's guidelines and specifications for maintenance and replacement procedures to ensure the longevity and reliability of the hydraulic motors.

- Q: What is the purpose of a concrete pump cylinder?

- The purpose of a concrete pump cylinder is to provide the necessary pressure and force to push the concrete mixture through the pumping system and into the desired location, allowing for efficient and precise placement of concrete in construction projects.

- Q: Can I get spare parts for both piston and rotary concrete pumps?

- Yes, spare parts are available for both piston and rotary concrete pumps.

- Q: How do I properly maintain and replace concrete delivery pipes in concrete pump spare parts?

- To ensure the concrete pump operates efficiently and safely, it is crucial to properly maintain and replace the concrete delivery pipes in spare parts. Here are some guidelines you can adhere to: 1. Conduct Regular Inspections: Frequently check the concrete delivery pipes for signs of wear, cracks, or damage. Look out for leaks or blockages that may hinder the concrete flow. Identify weak areas that may necessitate replacement. 2. Perform Thorough Cleaning: After each use, clean the concrete delivery pipes meticulously. Use water and a high-pressure hose to eliminate any concrete residue or buildup. This will prevent clogs and maintain a smooth concrete flow. 3. Apply Lubrication: Reduce friction and prevent concrete from adhering to the inner surface of the pipes by applying a suitable lubricant. This practice will elongate the life of the pipes and guarantee a seamless concrete flow. 4. Replace Worn-out Components: Regularly monitor the condition of the delivery pipes and promptly replace any worn-out or damaged parts. Over time, the pipes may corrode or develop cracks, thereby affecting their performance. Replace these components with premium spare parts to achieve optimal outcomes. 5. Handle with Care: Exercise caution when handling the concrete delivery pipes to avoid unnecessary damage. Refrain from dropping or mishandling the pipes during transportation or storage. Shield them from extreme weather conditions and store them in a secure, dry location. 6. Prioritize Training and Safety: Ensure that the personnel operating the concrete pump are well-versed in handling and maintaining the equipment. Educate them on the significance of regular inspections, cleaning, and part replacement. Emphasize safety protocols to prevent accidents and ensure the durability of the concrete delivery pipes. By adhering to these steps, you can effectively maintain and replace the concrete delivery pipes in spare parts for the concrete pump. Consistent maintenance and prompt part replacement will extend the lifespan of the pipes and guarantee a seamless concrete flow during construction projects.

Send your message to us

3M Welded Delivery Pipe for Schwing Concrete Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords