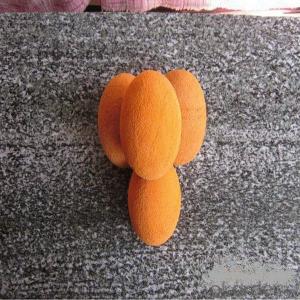

Concrete pump sponge ball DN100 for Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Product Name: CONCRETE PUMP CLEANING SPONGE BALL

1. Specification

Name | Material | Size | Function |

Clean Ball | Sponge Rubber | DN 80(3inch) | Clean pump pipe |

Clean Ball | Sponge Rubber | DN 100(4inch) | Clean pump pipe |

Clean Ball | Sponge Rubber | DN 125(5inch) | Clean pump pipe |

Clean Ball | Sponge Rubber | DN 150(6inch) | Clean pump pipe |

Clean Ball | Sponge Rubber | DN 200(8inch) | Clean pump pipe |

2. Application

1.Applacation:cleaning the pipeline of the concrete pump

2.Suitable for the various :Schwing CIFA PMZoomlion SANY and so on.

3. Package

Put into containers.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products have its ISO certifications, adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce Concrete Pump Cleaning Sponge Ball with Good Quality according to customers request?

A4: Yes, we can produce Concrete Pump Cleaning Sponge Ball according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: We have overseas branches all-around of world, If needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities &skilled personnel at site for training.

Image:

- Q: Are there any specific guidelines for the installation of wear plates or wear rings in concrete pump spare parts?

- Concrete pump spare parts, such as wear plates or wear rings, have specific guidelines for their installation. These guidelines guarantee proper installation and optimal equipment performance. Here are some essential guidelines to consider: 1. Prior to installation, thoroughly examine the wear plates or wear rings for any damage or defects. Replace any damaged or worn-out parts to ensure efficient operation. 2. Ensure that the concrete pump and all related components are clean and clear of debris or contaminants. Doing so will prevent premature wear and prolong the lifespan of the wear plates or wear rings. 3. Before installation, apply a suitable lubricant to the wear plates or wear rings. This will minimize friction and extend the components' service life. 4. Proper alignment is crucial for the effective functioning of wear plates or wear rings. Make sure the plates or rings are correctly aligned and securely fixed in place. Misalignment can cause premature wear and equipment damage. 5. Use the recommended torque specifications to tighten the bolts or fasteners that secure the wear plates or wear rings. Improper tightening can result in equipment malfunction or damage. 6. Implement a regular maintenance schedule to inspect and replace worn-out wear plates or wear rings. Regular maintenance will help detect and address any issues before they lead to major breakdowns or costly repairs. It is important to consult the manufacturer's guidelines and adhere to their specific instructions for the installation of wear plates or wear rings in concrete pump spare parts. Following these guidelines will ensure the equipment's optimal performance and longevity.

- Q: What is the role of a concrete pump cylinder in a pumping system?

- The role of a concrete pump cylinder in a pumping system is to generate the necessary hydraulic pressure to push the concrete through the pipeline. The cylinder works by converting the mechanical energy from the pump into hydraulic energy, allowing for efficient and controlled movement of the concrete.

- Q: How often should hopper screens be cleaned or replaced?

- It is important to clean or replace hopper screens regularly, usually every 3 to 6 months, depending on how often they are used and the type of materials being processed. Keeping the hopper screens clean is crucial for maintaining peak performance and preventing clogs or obstructions. If the screens become excessively dirty or damaged, they should be replaced immediately to avoid interruptions in material flow and potential equipment damage. Regularly maintaining and inspecting the hopper screens will help extend their lifespan and ensure the entire system operates smoothly.

- Q: Are there any specific cleaning and maintenance procedures for concrete pump spare parts?

- Yes, there are specific cleaning and maintenance procedures for concrete pump spare parts. For cleaning, it is important to remove any concrete buildup or residue from the spare parts regularly. This can be done by using a high-pressure water jet or by soaking the parts in a cleaning solution specifically designed for concrete. It is essential to follow the manufacturer's instructions when using cleaning agents to ensure the safety and effectiveness of the cleaning process. In addition to cleaning, regular maintenance is necessary to ensure the longevity and proper functioning of concrete pump spare parts. This includes inspecting the parts for any signs of wear, such as cracks or corrosion, and replacing them if necessary. Lubrication of moving parts, such as bearings or pistons, should also be done as per the manufacturer's recommendations. It is important to note that different concrete pump spare parts may require specific cleaning and maintenance procedures. Therefore, it is advisable to refer to the manufacturer's guidelines or consult with a qualified technician to determine the appropriate cleaning and maintenance procedures for each specific part.

- Q: How often should hopper agitator shafts be inspected or replaced in a concrete pump?

- Hopper agitator shafts in a concrete pump should be inspected regularly, ideally during routine maintenance checks, to ensure they are in proper working condition. The frequency of inspections may vary depending on the usage and operating conditions of the concrete pump. However, a general recommendation would be to inspect or replace hopper agitator shafts at least once every 6 to 12 months to prevent any potential issues or malfunctions.

- Q: What is the importance of a good quality concrete pump seal?

- A good quality concrete pump seal is important because it helps to prevent leakage and ensure the smooth and efficient operation of the pump. It helps to maintain the pressure and flow of the concrete, reducing the risk of blockages or malfunctions. A reliable seal also extends the lifespan of the pump by minimizing wear and tear on the internal components. Ultimately, a good quality concrete pump seal is crucial for achieving high-quality and consistent results in construction projects.

- Q: How can I determine if the concrete pump cylinder needs replacement?

- In order to determine whether the concrete pump cylinder needs replacement, several inspections and tests can be conducted. 1. Perform a visual inspection and look for any visible signs of wear and tear on the cylinder, such as cracks, dents, or corrosion. Additionally, check for leaks or excessive hydraulic fluid around the cylinder. 2. Evaluate the pump's performance during operation. Pay attention to any decrease in pumping efficiency, irregular flow, or decreased pressure, as these could indicate a problem with the cylinder. 3. Conduct a pressure test to assess the cylinder's ability to handle the required pressure. This can be done by isolating the cylinder and pressurizing it to a level higher than its typical operating pressure. If the cylinder fails to maintain pressure or shows signs of leakage, replacement may be necessary. 4. Measure the stroke length of the cylinder during operation. Uneven stroke lengths may indicate internal damage and could require replacement. 5. If you are uncertain about the cylinder's condition, seek consultation with professionals or experts in the field. They can provide a more accurate assessment and recommend the appropriate course of action, which may include cylinder replacement. Remember that regular maintenance and inspections are essential for the concrete pump's longevity and efficient operation. Addressing potential issues early on can help prevent further damage or accidents.

- Q: Can I get spare parts for concrete pump boom arms and pipes?

- Yes, spare parts for concrete pump boom arms and pipes are available. Many manufacturers and suppliers offer a wide range of spare parts specifically designed for concrete pump boom arms and pipes. These spare parts can be easily found and purchased from authorized dealers or online stores. It is important to ensure that you provide accurate specifications and details of your concrete pump model to find the correct spare parts for replacement or repair.

- Q: What is the importance of a concrete pump control valve?

- A concrete pump control valve plays a critical role in the operation of a concrete pump. It is an essential component that allows for precise and efficient control of the flow and pressure of the concrete being pumped. The importance of a concrete pump control valve can be understood by considering its various functions. Firstly, it regulates the flow of concrete from the hopper to the pumping cylinders. By adjusting the valve, operators can increase or decrease the flow rate to match the specific requirements of the project. This ensures that the right amount of concrete is being pumped, preventing wastage and optimizing productivity. Secondly, the control valve allows for precise control of the pressure in the pumping cylinders. By adjusting the valve, the operator can increase or decrease the pressure to maintain a consistent and steady flow of concrete. This is crucial in preventing blockages or clogs in the concrete pump system, which can lead to downtime and costly repairs. Furthermore, the control valve enables the operator to switch between different pumping modes, such as high-pressure pumping or low-pressure spraying. This versatility allows for the efficient execution of a wide range of concrete pumping tasks, from pouring foundations to spraying concrete for decorative purposes. In addition to its functional importance, a concrete pump control valve also contributes to the safety of the pumping operation. It allows operators to stop or reverse the flow of concrete in case of emergencies or equipment malfunctions. This feature ensures that any potential hazards are quickly addressed, minimizing the risk of accidents and injuries. Overall, the importance of a concrete pump control valve lies in its ability to provide precise control over the flow and pressure of concrete during pumping operations. It ensures efficiency, productivity, versatility, and safety, making it an indispensable component of any concrete pumping system.

- Q: How does a concrete pump hopper grate prevent clogs?

- Preventing clogs in the concrete pump system is a crucial function of the hopper grate. Acting as a filter, it permits only the necessary aggregate size to pass through, while capturing any excess debris or large particles that could cause blockages. Strategically placed openings or grids in the grate catch these unwanted materials. When pouring the concrete mixture into the hopper, the grate serves as a barrier. It allows only the appropriate material size to pass through, while obstructing any larger or undesirable debris. This ensures a smooth flow of concrete through the pump system, preventing any disruptions or jams during construction. Furthermore, the grate is typically constructed from durable materials like steel or high-density polyethylene. These materials are resistant to damage and wear, allowing the grate to withstand the high-pressure environment and continuous operation without deformation. Regular maintenance and cleaning of the hopper grate are also essential to prevent clogs. By inspecting and removing any accumulated debris or build-up on a regular basis, operators can ensure that the grate remains clear and fully functional, thereby preventing potential clogging issues. In conclusion, the concrete pump hopper grate acts as a filter to prevent clogs, allowing only the necessary aggregate size to pass through while capturing larger particles and debris. Its design and durable material ensure a smooth flow of concrete, minimizing the risk of blockages and maintaining construction efficiency.

Send your message to us

Concrete pump sponge ball DN100 for Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords