3M Welded Delivery Pipe for Sany Concrete Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

3M Welded Delivery Pipe for Sany Concrete Pump

1. Structure of 3M Welded Delivery Pipe for Sany Concrete Pump:

St52 Weld Pipe: Main use for Trailer-mounted pump, thickness has 4.0mm, 4.5mm, 5mm. Compare with for Truck-mounted pump. Weld pipe has cheaper price, so it is popular in Saudi, Pakistan, India, etc. Unit Price is about 30USD-33USD.

St52 Seamless Pipe: Now More People like use this kind for Truck Pump and Trailer Pump because of the quality is better and it is seamless kind, so this kind pipe is most popular in Middle East Price About 34USD-37USD.

Wear Resistant Pipe: Use for Truck Pump, Wear Resistant Layer is 2.5mm.Through heat treatment way make this pipe more strong (HRC60-62), Using Life: 25,000m³-35,000m³ Price about 65USD-68USD.

Two Wall Pipe: This pipe thickness (2mm+2.5mm), Using Life about 50,000m³-60,000m³

2. Main Features of 3M Welded Delivery Pipe for Sany Concrete Pump:

• High Wear-resistant, long service life, lower cost

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Provide consumers with regular visits

• Ensure the supply of ancillary parts

• Our company passed the ISO9000 certification, the product through 3C certification in full compliance with national standards

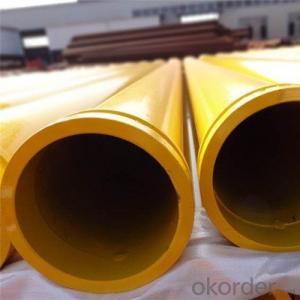

3. 3M Welded Delivery Pipe for Sany Concrete Pump Images

4. 3M Welded Delivery Pipe for Sany Concrete Pump Specification

Production Process

5. FAQ

We have organized several common questions for our clients, may help you sincerely:

①Is your products exported a lot?

We have exported to many, many countries. Every year we ship more than 30 containers of these spare parts. Our main market is in Middle-east, Asia & Africa.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 15 working days can be served.

6. Why choose us

• We are a comprehensive manufacturing and trading company.

• Our company is one of the biggest manufacturing and trading companies in China.

• We have been specialized in producing concrete pump spare parts and specialized in producing all kinds of concrete pump parts. As Concrete Pump Pipe, Concrete Pump Elbow, Concrete Pump Rubber Hose, Concrete Pump Wear Plate, Concrete Pump S Valve, Concrete Pump Piston and so on.

• We are famous for our superior quality, competitive prices, first-class craftworks, safe package and prompt delivery.

• We have been supplying concrete pump parts for SCHWING, PUTZMEISTER, SANY, CIFA, KYOKUTO, ZOOMLION for 10 years, so we can promise you the quality and best price.

- Q: What are the signs of a damaged concrete pump S valve?

- Some signs of a damaged concrete pump S valve may include leaks, reduced pumping efficiency, irregular or interrupted flow of concrete, excessive wear on the valve components, and difficulty in controlling the concrete output.

- Q: How often should concrete pump remote controls be inspected and maintained?

- Concrete pump remote controls should be inspected and maintained on a regular basis to ensure their proper functioning and to prevent any potential issues. The frequency of inspections and maintenance will depend on various factors such as the intensity of use, environmental conditions, and the specific recommendations provided by the manufacturer. As a general guideline, it is recommended to inspect and maintain concrete pump remote controls at least once every three months. This includes checking for any visible damage, loose or worn-out parts, and ensuring that all buttons and switches are working properly. Additionally, it is important to inspect and clean the battery compartment, and replace batteries if necessary. However, in high-demand situations or extreme environmental conditions, more frequent inspections and maintenance may be required. For instance, if the concrete pump is used in a harsh environment with excessive dust or moisture, it may be necessary to increase the frequency of inspections and cleanings to prevent any potential damage or malfunction. It is also crucial to follow the manufacturer's guidelines and recommendations for maintenance. They may provide specific instructions on lubrication, calibration, or other maintenance procedures that should be performed at regular intervals. By adhering to these guidelines, concrete pump remote controls can be kept in optimal condition, ensuring safe and efficient operation.

- Q: How often should control system sensors be calibrated or replaced?

- The frequency at which control system sensors should be calibrated or replaced depends on several factors. These factors include the type of sensor, its application, environmental conditions, and the manufacturer's recommendations. In general, it is recommended to calibrate control system sensors at least once a year. However, certain sensors may require more frequent calibration due to their sensitivity or criticality in the system. For example, sensors used in safety-critical applications or those that are exposed to harsh environmental conditions may need to be calibrated more frequently, such as every six months or even quarterly. Additionally, it is important to monitor the performance of control system sensors regularly to ensure accurate readings and reliable operation. This can be achieved through routine maintenance and periodic checks. If any signs of sensor drift, inconsistency, or failure are observed during these checks, immediate calibration or replacement may be necessary. Moreover, the manufacturer's recommendations play a significant role in determining the calibration or replacement intervals. Each sensor has its own specifications and guidelines provided by the manufacturer. It is essential to follow these recommendations to maintain optimal performance and extend the lifespan of the sensor. Ultimately, the calibration or replacement frequency of control system sensors should be determined by a combination of factors including industry standards, application requirements, environmental conditions, and manufacturer's guidelines. Regular monitoring, routine maintenance, and adherence to these factors will ensure that control system sensors operate accurately and reliably.

- Q: Can concrete pump spare parts be replaced individually, or should they be replaced as a set?

- Typically, individual replacement of concrete pump spare parts is possible, eliminating the need to replace the entire set. This advantageous approach enables economical maintenance and repair of the pump. By solely replacing the faulty or worn-out part, operators can ensure the pump's optimal functionality without incurring unnecessary expenses. Furthermore, individual part replacement offers enhanced flexibility and customization since different components wear out at varied rates based on their usage. However, it is worth noting that some manufacturers may recommend replacing certain parts as a set or in specific combinations to achieve optimal performance. Consequently, it is always advisable to consult the manufacturer's guidelines or seek professional advice when replacing spare parts for concrete pumps.

- Q: What are the signs of a malfunctioning concrete pump outrigger?

- There are multiple indicators that point towards a malfunctioning concrete pump outrigger. 1. An uneven or unstable platform may suggest that the outrigger is not functioning properly. This can be observed when the pump is not level or when the platform exhibits excessive movement or shaking. 2. The presence of hydraulic fluid leaks in the outrigger's hydraulic system is a telltale sign of malfunction. If you notice puddles or stains on the ground caused by hydraulic fluid, it signifies a problem. 3. If the outrigger is slow to extend or retract, or if it does not respond to the controls, it indicates a malfunction. This can jeopardize the stability of the pump and should be taken seriously. 4. Unusual noises emanating from the outrigger, such as grinding, whining, or knocking sounds, can be indicative of mechanical issues or loose components. Ignoring these noises may lead to underlying problems that require attention. 5. It is crucial to visually inspect the outrigger for any visible damage, such as bent or cracked components, loose bolts, or missing parts. These physical signs of damage can impair the functionality and stability of the outrigger. Regular inspection and maintenance of the concrete pump outrigger are essential for ensuring safe and efficient operation. If any of these signs are present, it is advisable to cease using the pump and have it inspected and repaired by a qualified professional to prevent further damage or accidents.

- Q: Are there any warranties or guarantees available for concrete pump spare parts?

- Yes, there are warranties and guarantees available for concrete pump spare parts. Many manufacturers and suppliers offer warranties to ensure the quality and performance of their products. These warranties typically cover defects in materials or workmanship and provide a certain period of coverage, usually ranging from a few months to a year or more. Additionally, some suppliers may offer guarantees on the performance or durability of their spare parts, providing assurance and peace of mind to the customers. It is always recommended to inquire about the specific warranty or guarantee terms before purchasing concrete pump spare parts to ensure that you are protected in case of any issues.

- Q: How long does it take to receive concrete pump spare parts after placing an order?

- The time it takes to receive concrete pump spare parts after placing an order can vary depending on several factors. Firstly, it depends on the availability of the specific spare parts you have ordered. If the parts are readily available in stock, the delivery time can be relatively quick. However, if the parts are not in stock and need to be manufactured or sourced, it may take longer to receive them. Secondly, the location and distance between the supplier and your location also play a role in the delivery time. If the supplier is in close proximity, the parts can be delivered within a few days. However, if the supplier is located far away or in a different country, it may take longer due to shipping and customs processes. Furthermore, the shipping method you choose can also impact the delivery time. Expedited shipping options can ensure quicker delivery, but at an additional cost. Standard shipping methods may take longer but are usually more cost-effective. Lastly, the efficiency and responsiveness of the supplier also come into play. A reliable supplier with a streamlined ordering and shipping process will likely be able to deliver the spare parts in a shorter time frame. In conclusion, the time it takes to receive concrete pump spare parts after placing an order can vary based on factors such as availability, location, shipping method, and supplier efficiency. It is advisable to inquire about estimated delivery times when placing the order to have a better understanding of when the parts will be delivered.

- Q: What is the purpose of a concrete pump control panel?

- Operators use a concrete pump control panel to centrally control different functions and parameters of the concrete pump. By using this panel, operators can initiate and halt the pump, manage its speed and direction, and monitor and regulate the flow and pressure of the concrete being pumped. Safety measures like emergency stop buttons and alarms are also incorporated in the control panel to safeguard both the operators and the equipment. Additionally, the control panel may have diagnostic capabilities that present real-time data and alerts for maintenance and troubleshooting purposes. In summary, the aim of a concrete pump control panel is to improve efficiency, precision, and safety in the concrete pumping process.

- Q: What are the signs of a malfunctioning gearbox?

- Some signs of a malfunctioning gearbox include grinding or whining noises coming from the transmission, difficulty in shifting gears, slipping gears, delayed engagement or disengagement of gears, and leaking transmission fluid.

- Q: How can one determine the correct hardness and durometer rating for rubber components in concrete pump spare parts?

- Several factors must be taken into consideration when determining the appropriate hardness and durometer rating for rubber components in concrete pump spare parts. To begin with, it is crucial to have a thorough understanding of the specific application requirements of the rubber components. This entails considering factors such as pressure, temperature, and frequency of use. Additionally, it is important to assess the compatibility of the rubber material with concrete and any other chemicals that may come into contact with the components. Ensuring chemical resistance is vital for guaranteeing the longevity and durability of the rubber parts. Furthermore, the anticipated load and stress on the rubber components must be carefully analyzed. This includes evaluating the weight of the concrete, the force exerted during pumping, and the potential for impact or abrasion. Moreover, environmental conditions should not be overlooked. Exposure to sunlight, extreme temperatures, or harsh weather conditions can significantly impact the performance and lifespan of rubber components. It is also essential to consider the specific type of rubber material being used. Different rubber compounds possess varying hardness and durometer ratings. Seeking guidance from rubber manufacturers or suppliers who specialize in concrete pump spare parts can provide valuable insights and recommendations based on their expertise and experience. Ultimately, determining the correct hardness and durometer rating for rubber components in concrete pump spare parts necessitates a meticulous evaluation of application requirements, compatibility, load and stress factors, environmental conditions, and expert advice.

Send your message to us

3M Welded Delivery Pipe for Sany Concrete Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords