316 Stainless Steel Sheet Hot Rolled NO.1

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 2400 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

CNBM International Corporation

CNBM International Corporation

Stainless steel

CNBM began to domestic trade since 70S,now we also sell stainless steel aborad.

We are the agent of TISCO,BAOSTEEL,LISCO,JISCO,ZPSS.

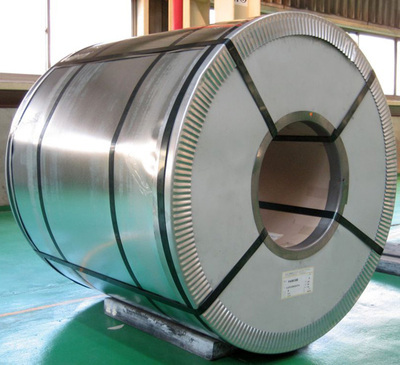

Our main products are stainless steel inox sheet/plate,coil/roll,strip,bar,angle,pipe and tube.

Grade-- 201,202,304,304L,316,316L,310S,309S,301,321,904L,410,420,430,409.

Surface--2B,BA,No.4/HL/Hairline/brushed/satin,8K/No.8/mirror,SB,gold,etch,No.1,polish.

Thickness--0.2-6mm for cold rolled; 3-150mm for hot rolled.

Width:10mm-2000mm for coil.

Standard size --1000×2000mm,1219×2438mm=4ft×8ft=1220×2440mm,

1250×2500mm,1500×3000/6000mm,1524×6096mm.For sheets/plates.

Certificate--ISO,BV,SGS,TUV,IQI or other third inspections.

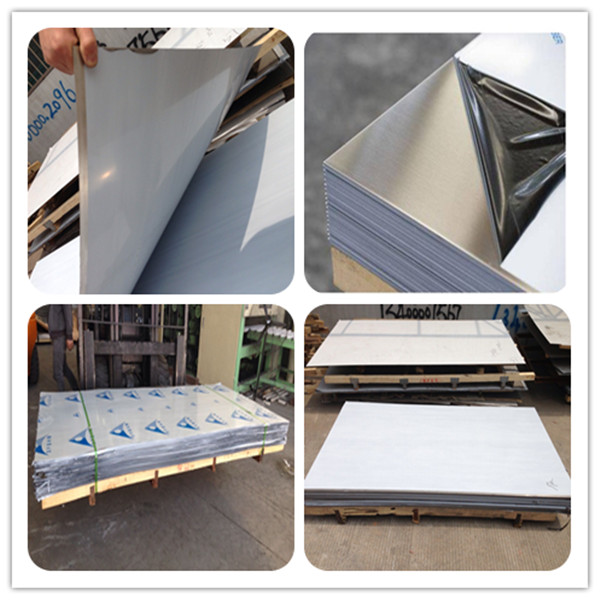

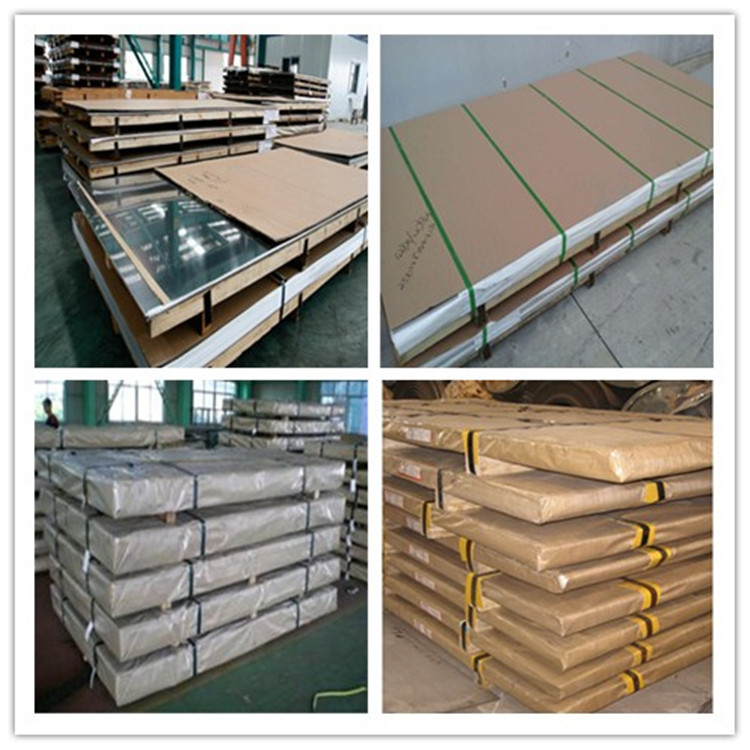

Package--wooden pallets with fimugated,iron pallets,water proof papers,

interleaved paper,pvc film,20'GP or 40'GP container.

Product Description

Description of 316 stainless steel hot rolled no.1

1 | Product Name | 316 stainless steel hot rolled no.1 |

2 | Material | ASTM 301, ASTM304,ASTM304L, ASTM 316, ASTM316Ti,ASTM309S, ASTM310S, ASTM321, ASTM347H,ASTM A317,ASTMA317L, ASTM409,ASTM409L,ASTM410,ASTM420,ASTM430 ASTM 201,ASTM202, |

3 | Technique | Cold Rolled Stainless Steel plate Cold Drawn Stainless Steel plate Hot Rolled Stainless Steel plate |

4 | Standard | ASTM,AISI,ASME,JIS,SUS,DIN,EN,GB,BS |

5 | Thickness | 0.2-6.0mm for cold rolled 3.0-300mm for hot rolled |

Width | 600-3000mm | |

Length | Any, as your requirement | |

6 | Surface Treatment | No.1, NO.4 ,2B, BA, Hair Line,8K,Brush,Embossed and Mirror Finish or as your demand |

7 | Packing | Standard export packing-For stainless steel sheet 1.surface polish 2. bundle package 3. wooden case , wooden pallet package 4:container or bulk 5. special according to customer request |

8 | Delivery | Normally according to the order quantity or upon negotiation |

9 | Price Item | FOB,CFR,CIF Or as negotiated |

10

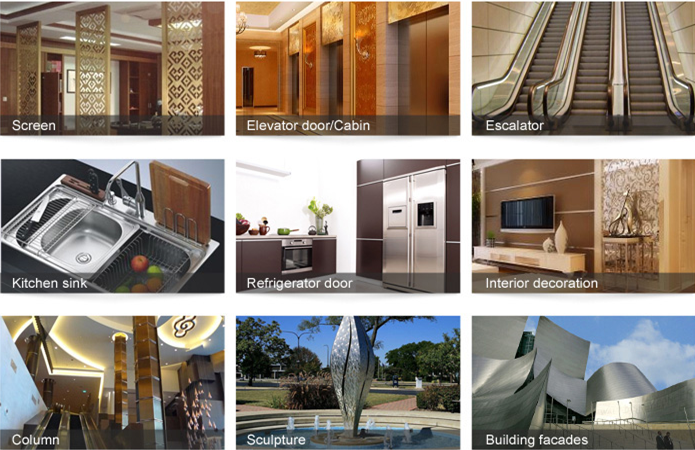

| Application | Stainless Steel plate are widely used in below fields: 1: Construction feild,shipping building industry 2: Petroleum and Chemical Industries 3: Food and Machenical Industries 4: Boiler Heat Exchange 5: Machinery and Hardware Industries |

Production of 316 stainless steel hot rolled no.1

Mechanical property of 316 stainless steel hot rolled no.1

| Tensile Strength | σb (MPa)≥520 |

| Offset Yield Strength | σ0.2 (MPa)≥205 |

| Elongation | δ5 (%)≥40 |

| Hardness | ≤187HB;≤90HRB;≤200HV |

| Density(20℃,g/cm3) | 7.98 |

Chemical composition of 316 stainless steel hot rolled no.1

| 316 | C | Si | Mn | P | S | Ni | Cr | Mo |

| % | ≤0.08 | ≤1 | ≤2 | ≤0.035 | ≤0.030 | 10.0~14.0 | 16.0~18.5 | 2.00-3.00 |

Maintenance of 316 stainless steel hot rolled no.1

Regular cleaning and maintenance

Pay attention to prevent the occurrence of the phenomenon of surface scratches

Use soap, weak detergent or warm water to remove surface dust, dirt

In addition to the surface of the binder with alcohol or an organic solvent (ether, benzene)

Use neutral detergent or ammonia solution in addition to surface oil

With 10% nitric acid or abrasive detergent in addition to the surface of the embroider caused by the dirt.

Packaging & Shipping

1, Packaging: seaworthy package or as required

2, Delivery: 35-45 days or based on quantity

After-sale service:

CNBM provides the services and support you need for every step of our cooperation.

We’re the business partners you can trust; you can relax and get on with doing business.

For any problem, please kindly contact us at any your convenient time,

we’ll reply you in our first priority within 24 hours

Application

F A Q

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories

- Q: What are the limitations of using stainless steel sheets?

- There are several limitations associated with using stainless steel sheets. Firstly, stainless steel sheets can be quite expensive compared to other materials. This can make it less feasible for certain budget-conscious projects or applications. Secondly, stainless steel sheets are relatively heavy, which can make them difficult to handle and install, especially in large quantities. This can increase labor costs and require additional equipment for transportation and installation. Thirdly, stainless steel sheets are prone to scratching and denting. While stainless steel is known for its durability, it is not entirely resistant to physical damage. Scratches and dents can diminish the appearance and functionality of the sheets, particularly in high-traffic areas or environments where there is a risk of impact. Additionally, stainless steel sheets can be susceptible to corrosion, although to a lesser extent compared to other metals. In certain conditions, such as exposure to saltwater or harsh chemicals, stainless steel sheets may develop rust or other forms of corrosion. Regular maintenance and proper care are necessary to prevent or minimize this issue. Another limitation is that stainless steel sheets have limited color options. They generally come in shades of silver or gray, which may not be suitable for projects that require specific colors or aesthetics. Lastly, stainless steel sheets have poor insulation properties. They conduct heat and cold more efficiently than other materials, which can result in greater energy loss and higher heating or cooling costs. In applications where insulation is crucial, additional measures or alternative materials may be required. In conclusion, while stainless steel sheets offer numerous advantages such as strength, corrosion resistance, and durability, they also have limitations in terms of cost, weight, susceptibility to damage, corrosion, limited color options, and poor insulation properties. Understanding these limitations is crucial when considering the use of stainless steel sheets in various applications.

- Q: What are the standard sizes of stainless steel sheets?

- The standard sizes of stainless steel sheets vary depending on the specific industry and application. However, there are some commonly used standard sizes that are widely available. In the architectural and construction industry, the standard sizes of stainless steel sheets typically range from 4 feet by 8 feet (1220mm x 2440mm) to 5 feet by 10 feet (1524mm x 3048mm). These sizes are commonly used for cladding, roofing, and interior design applications. In the manufacturing and industrial sectors, stainless steel sheets come in various sizes, including 4 feet by 8 feet, 4 feet by 10 feet (1220mm x 3050mm), and even larger sizes like 5 feet by 12 feet (1524mm x 3658mm). These larger sizes are often used for fabrication, industrial machinery, and equipment manufacturing. It's important to note that custom sizes can also be fabricated based on specific project requirements. These custom sizes may include narrower or wider widths, longer or shorter lengths, or even different thicknesses to meet the needs of a particular application. Ultimately, the standard sizes of stainless steel sheets are determined by industry standards, market demand, and the capabilities of the manufacturers. It's always advisable to consult with suppliers or manufacturers to ensure the availability of the desired size before making a purchase.

- Q: Are stainless steel sheets suitable for outdoor sculptures or decorative pieces?

- Yes, stainless steel sheets are highly suitable for outdoor sculptures or decorative pieces. Stainless steel is known for its durability, resistance to corrosion, and ability to withstand harsh weather conditions, making it an ideal choice for outdoor applications. Additionally, its sleek and polished appearance adds a touch of elegance and modernity to any outdoor space.

- Q: What are the different types of stainless steel sheet finishes for food processing applications?

- There are several types of stainless steel sheet finishes commonly used in food processing applications. These include mill finishes, which are smooth and unpolished; 2B finishes, which are slightly reflective and have a smooth, matte appearance; and mirror finishes, which have a highly reflective surface. Additionally, there are also brushed finishes, which have a textured appearance, and embossed finishes, which feature raised patterns or designs on the surface.

- Q: What are the different types of stainless steel sheet grades available?

- There are several different types of stainless steel sheet grades available, including 304, 316, 430, and 201. Each grade has its own unique properties and applications, making them suitable for various industries and purposes.

- Q: Are stainless steel sheets suitable for water treatment plants?

- Water treatment plants find stainless steel sheets highly suitable due to their excellent corrosion resistance. In such facilities, materials are constantly exposed to water and various chemicals, making this resistance crucial. Stainless steel sheets resist rust and corrosion caused by water, chlorine, chloramines, and other commonly used disinfectants in water treatment processes. Moreover, stainless steel can withstand high temperatures, making it ideal for use in water treatment plants that apply heat during specific treatment processes. Additionally, stainless steel is hygienic and easy to clean, ensuring the water remains free from contaminants or impurities. Overall, stainless steel sheets are a reliable and long-lasting choice for water treatment plants because of their corrosion resistance, durability, and hygienic properties.

- Q: Are stainless steel sheets suitable for water tanks?

- Yes, stainless steel sheets are suitable for water tanks. Stainless steel is highly resistant to corrosion and rust, making it an ideal material for water storage. It is durable, long-lasting, and can withstand high water pressures. Additionally, stainless steel is hygienic, easy to clean, and does not contaminate the water.

- Q: Can stainless steel sheets be used for kitchen appliances?

- Kitchen appliances can indeed utilize stainless steel sheets. The reason behind its popularity in this realm is its robustness, ability to resist corrosion, and effortless upkeep. Ovens, refrigerators, dishwashers, and other kitchen appliances are often crafted with this versatile material. It can be effortlessly molded into diverse shapes and sizes, accommodating a variety of appliance designs. Furthermore, stainless steel's sleek and contemporary aesthetics have made it the preferred option for countless homeowners and chefs.

- Q: What are the different types of stainless steel sheet embossing patterns available?

- There are various types of stainless steel sheet embossing patterns available, including diamond, linen, quilted, hammered, and checker plate.

- Q: How do stainless steel sheets compare to other materials like aluminum or carbon steel?

- In various industries, stainless steel sheets are preferred over other materials like aluminum or carbon steel for several reasons. Firstly, stainless steel sheets possess excellent corrosion resistance, making them suitable for environments with moisture or corrosive elements. In comparison, aluminum, although corrosion-resistant, is not as durable as stainless steel in harsh conditions, and carbon steel is prone to rust. Secondly, stainless steel sheets are renowned for their strength and durability. They have a higher tensile strength than aluminum, making them more resistant to bending and deformation. Carbon steel shares similar strength characteristics but is more susceptible to corrosion, especially in exposed applications. Moreover, stainless steel sheets can withstand high temperatures without compromising their structural integrity. They exhibit excellent heat resistance properties, making them ideal for applications involving heat transfer or exposure to extreme temperatures. Conversely, aluminum has lower heat resistance, while carbon steel can lose strength and become brittle when subjected to high temperatures. Additionally, stainless steel sheets are non-porous and easy to clean, making them a popular choice in industries where hygiene is critical, such as food processing or medical equipment. In contrast, aluminum and carbon steel may have more porous surfaces that can harbor bacteria or contaminants. Furthermore, stainless steel sheets offer a sleek and modern appearance that is often desired in architectural and design applications. They can be easily polished or finished to achieve various decorative effects. While aluminum and carbon steel sheets are also versatile, they may not provide the same level of aesthetic appeal. However, it is important to note that stainless steel sheets may be more expensive than aluminum or carbon steel due to their superior properties. The choice of material ultimately depends on the specific requirements of the application, including factors such as cost, strength, corrosion resistance, and aesthetics.

Send your message to us

316 Stainless Steel Sheet Hot Rolled NO.1

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 2400 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords