Hot Rolled Stainless Steel Coils 316 NO.1 Finish

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Products Description for Stainless Steel Coils/Sheets:

Product | stainless steel coils/plates/sheets | ||

Discharge Port | Any Port, China | ||

Size | Coils | Cold Rolled: | Thickness0.3-8mm,Width:280-2100mm |

Hot Rolled : | Thickness3-14mm,Width:650-2100mm | ||

Plates | Thickness2-80mm,Width:1500-3000mm | ||

Coil Weight | About 20 Tons | ||

Grade | 201,202,304/304L/304H,316/316L/316H,321/H,310S,409/L,430 etc. | ||

Technique | Hot Rolled/Cold Rolled | ||

Finish | 2B, BA, 2D, No1, No2, No4,NO.8,SB etc | ||

Edge | Mill Edge / Slitting Edge | ||

Package | In bundles, or as customer's requirement | ||

Place of Origin | Made in China | ||

MOQ | 20 Tons | ||

Specifications for Stainless Steel Coils/Sheets:

Name: stainless steel coils/plates/sheets

Discharge Port: Any Port, China

Cold Rolled Size: Thickness0.3-8mm,Width:280-2100mm

Hot Rolled Size: Thickness3-14mm,Width:650-2100mm

Hot Rolled/Cold Rolled Plates : Thickness2-80mm,Width:1500-3000mm

Coil Weight: About 20 Tons

Grade: 201,202,304/304L/304H, 316/316L/316H, 409/L,430 etc.

Technique: Hot Rolled/Cold Rolled

Finish:2B, BA, 2D, No1, No2 etc

Edge: Mill Edge / Slitting Edge

Packaging: In bundles, or as customer's requirement

Place of Origin: Made in China

MOQ: 20 Tons

Payment Terms: 100% LC at sight, or 100%TT in advance

Delivery Time: With 30-40 days after deposit

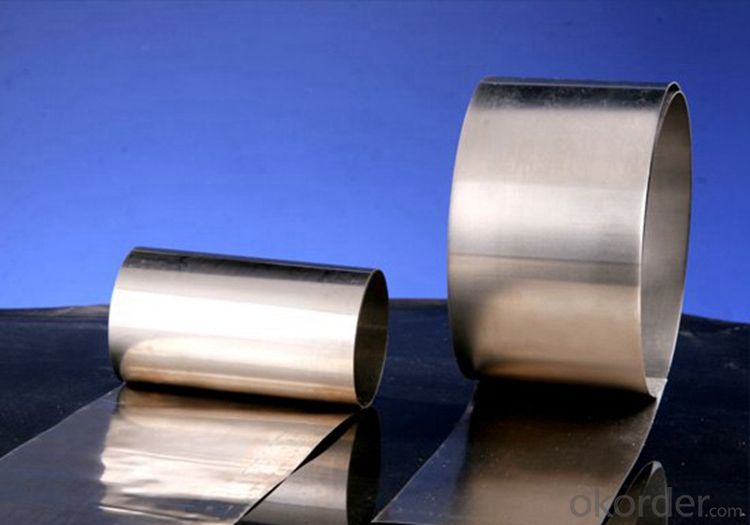

Detail picture for Stainless Steel Coils/Sheets

Features of Stainless Steel Coils

(1)Good ductility

(2)Good corrosion resistance

(3)Excellent abrasion resistance and fatigue strength

(4)Good weldability

(5)Oxidation resistant performance

(6)Excellent in high temperature

Payment&Delivery for Stainless Steel Coils/Sheets:

Payment Terms | 100% LC at sight,or 30%TT in advance, balance against B/L copy |

Delivery Time | With 30-40 days after deposit |

Price Terms | Ex-Work, FOB, CNF, CFR, CIF,etc |

Application of Stainless Steel Coils

Boiler heat exchanger, machinery andpetroleum ,chemical industries, hardware fields,Food industry,construction material,kitchen utensils, building construction, medical equipment,chemical tank, pipe etc

FAQ for Stainless Steel Coils/Sheets:

Q: How long is the delivery time?

A: Normally 30-40 days, but mostly according to the specific requirements or the quantity

Q: Could you send me sample?

A: We can supply you with the sample for free, but the delivery charges will be covered by customers.

- Q: Can stainless steel sheets be used for electrical conductivity?

- Yes, stainless steel sheets can be used for electrical conductivity as they have relatively low electrical resistance and are often used in applications where electrical current needs to flow efficiently.

- Q: Do stainless steel sheets have a warranty?

- Yes, stainless steel sheets typically come with a warranty. The length and terms of the warranty may vary depending on the manufacturer or supplier. It is recommended to check with the specific company or review the product documentation for information on the warranty coverage.

- Q: Can stainless steel sheets be used for elevator flooring?

- Yes, stainless steel sheets can be used for elevator flooring. Stainless steel is a popular choice for elevator flooring due to its durability, strength, and resistance to corrosion. It is able to withstand heavy foot traffic and is easy to clean and maintain. Additionally, stainless steel is visually appealing and can add a sleek and modern look to elevators.

- Q: How do stainless steel sheets resist corrosion?

- Stainless steel sheets resist corrosion due to the presence of chromium, which forms a protective layer on the surface of the material. This layer, known as chromium oxide, acts as a barrier against moisture, oxygen, and other corrosive substances, preventing them from reaching the underlying steel and causing corrosion.

- Q: Can stainless steel sheets be used for automotive body panels?

- Yes, stainless steel sheets can be used for automotive body panels. Stainless steel is a popular choice for automotive applications due to its excellent corrosion resistance, high strength, and durability. It can withstand harsh weather conditions, road salts, and other environmental factors without rusting or degrading. Additionally, stainless steel is lightweight, making it ideal for reducing the overall weight of the vehicle and improving fuel efficiency. However, stainless steel can be more expensive compared to other materials, which may affect its widespread use in automotive body panels.

- Q: Are stainless steel sheets suitable for chemical processing plants?

- Yes, stainless steel sheets are highly suitable for chemical processing plants. Stainless steel is known for its excellent corrosion resistance, making it ideal for environments where chemicals are present. It is resistant to a wide range of chemicals, including acids, alkalis, and solvents, which are commonly used in chemical processing plants. Stainless steel sheets also offer high strength and durability, allowing them to withstand harsh operating conditions and maintain their structural integrity over time. They are also easy to clean and maintain, ensuring a hygienic environment in chemical processing plants. Additionally, stainless steel sheets have good thermal properties, making them suitable for applications involving high or low temperatures. They also exhibit low magnetic permeability, which can be beneficial in certain chemical processing operations. Overall, stainless steel sheets are a popular choice in chemical processing plants due to their corrosion resistance, strength, durability, and ease of maintenance.

- Q: What is called anti fingerprint stainless steel sheet?

- Anti fingerprint (also known as non fingerprint) stainless steel plate is a protective layer treatment process is extremely thin and solid formed on the surface of stainless steel by nano coating technology, the stainless steel surface can not only achieve the anti fingerprint effect, but also can improve the ability of anti corrosion; and processing, such as bending or stamping processing can meet the general request.

- Q: Can stainless steel sheets be used for elevator handrails or grab bars?

- Yes, stainless steel sheets can be used for elevator handrails or grab bars. Stainless steel is a popular choice for these applications due to its durability, corrosion resistance, and aesthetic appeal. Stainless steel sheets can be fabricated into various shapes and sizes to meet the specific requirements of elevator handrails or grab bars, ensuring safety and comfort for users. Additionally, stainless steel is easy to clean and maintain, making it a practical choice for high-traffic areas such as elevators.

- Q: Can stainless steel sheets be used for food packaging or containers?

- Food packaging or containers can indeed utilize stainless steel sheets. The food industry widely employs stainless steel due to its numerous advantageous qualities. Its corrosion resistance guarantees that the food will not react with the container, ensuring safety for consumption. Moreover, stainless steel is highly durable, making it appropriate for long-term utilization in food packaging or containers. It is also effortless to clean and maintain, meeting the necessary hygiene standards. Furthermore, stainless steel containers or packaging can withstand extreme temperature changes, making them suitable for diverse food storage and transportation requirements. All in all, stainless steel sheets are a dependable and secure option for food packaging or containers.

- Q: Can stainless steel sheets be used for water tanks or storage containers?

- Yes, stainless steel sheets can be used for water tanks or storage containers. Stainless steel is known for its durability, corrosion resistance, and hygienic properties, making it an excellent choice for storing water or other liquids. It is commonly used in various industries, including food and beverage, pharmaceuticals, and chemical storage, due to its ability to maintain the quality and purity of the stored substances.

Send your message to us

Hot Rolled Stainless Steel Coils 316 NO.1 Finish

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords