Stainless Steel 1/2 Tubing

Stainless Steel 1/2 Tubing Related Searches

1/2 Stainless Steel Tubing 1 2 Stainless Steel Tubing 1/4 Stainless Steel Tubing 1 2 Inch Stainless Steel Tubing Stainless Steel 1/2 Rod 1 Stainless Steel Tubing 2 Stainless Steel Tubing 1 Inch Stainless Steel Tubing 3/4 Stainless Steel Tubing 1in Stainless Steel Tubing 1 2 Stainless Steel Pipe Seamless Stainless Steel Tubing 1 4 Stainless Steel Tubing 1 1 2 Stainless Steel Pipe Stainless Steel Tubeing 3/8 In Stainless Steel Tubing Stainless Steel Tubs Stainless Steel Tub Stainless Steel Coil Tubing 2 Stainless Steel Pipe 2 Inch Stainless Steel Pipe 1 Stainless Steel Pipe Bending Stainless Steel Tubing 1/2 Aluminum Plate 1/2 Thick Aluminum Plate 1 Inch Stainless Steel Pipe Stainless Steel Tubing Sizes Stainless Steel Tubes 3/8 Stainless Steel Tubing 1/4 In Stainless Steel PlateStainless Steel 1/2 Tubing Supplier & Manufacturer from China

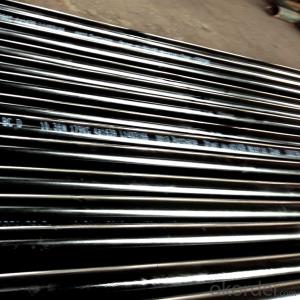

Stainless Steel 1/2 Tubing is a type of metal tubing made from stainless steel, which is known for its corrosion resistance, strength, and durability. This tubing is available in various sizes and thicknesses, making it suitable for a wide range of applications across different industries. The product's versatility and robustness make it a popular choice for many professionals and businesses.Stainless Steel 1/2 Tubing finds its application in numerous scenarios, such as in the construction of pipelines, mechanical components, and structural frameworks. Its resistance to corrosion and ability to withstand high temperatures make it ideal for use in environments where other materials might fail. Additionally, its sleek and modern appearance makes it a popular choice for decorative purposes in various architectural and design projects.

Okorder.com is a leading wholesale supplier of Stainless Steel 1/2 Tubing, offering a vast inventory of this product to cater to the needs of various customers. With a commitment to providing high-quality materials at competitive prices, Okorder.com ensures that businesses and individuals can access the stainless steel tubing they require for their projects without compromising on quality or budget.

Hot Products