Stainless Steel Sheet 310S hot rolling NO.1

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

TISCO 310S stainless steel sheet

Features:

1.Accurate dimension

2.Minimum mainenance

3.Excellent service life

4.Non Corrosive

5.Heat Resistant

Detail information:

1. Steel grade: 310S

2. Surface: 2B, BA, No. 4, 8K(mirror), HL, embossing, etching. And more than 100 different patterns for your choice.

3. Colors: Golden, rose golden, titanium golden coating, champagne golden, brown, bronze, titanium black, sapphire blue, purple, gray, silver, coffee champagne, jade-green, etc.

4. Thickness: 0.3-120mm

5. Width: 500mm, 1000mm, 1219mm, 1500mm, 1800. And length: Could be cut into any size as per customer's request. Usually our common sizes: 1219mm*2438mm (4*8ft), 1219mm*3048mm (4*10ft) and 1000mm*2000mm.

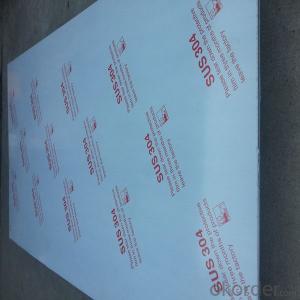

6. Standard: AISI, SUS, etc.

7. Packing: Standard sea-worthy packing, cover with PVC, and wooden case, or customize package.

8. Application:

Architectural decoration, luxury doors, wall decoration plate, elevators decorating, KTV indoor decoration, metal tank shell, ship building, decoration inside the train, as well as outdoor works, advertising name plate, the ceiling and cabinets, aisle panels, screen, the tunnel project, hotels, guest houses, entertainment place, kitchen equipment, light industrial and others.

9. Advantage: Colorful, showing the splendor of your quality, wear-resistant as well, strong corrosion resistance, anti-rust property and decorative effect, durable and beautiful in good taste.

10. Supplier Product Code: SDJM

11. Competitive Advantages of the product

1) Stainless Steel Decorative Sheet

2) Customize pattern and color coating

3) Advantage: Various patterns, splendid decorative effect, fashionable design

4) Surface finish: Mirror, 2b, no.1, no.4, 6k, 8k, polished, etc

1. Material: TISCO 310S

2. Standard: ASTM, AISI,JIS, DIN,GB

3.Cold rolled stainless steel sheet

Thickness : 0.3mm-3.0mm

Width : 1000mm/1219mm/1500mm

Length : 2000mm/2438mm/4000mm/6000mm or cutting randomly

Model size : 0.3mm-3.0mm(TK)*1000mm(W)*2000mm(L)

0.3mm-3.0mm(TK)*1219mm(W)*2438mm(L)

0.3mm-3.0mm(TK)*1500mm(W)*4000mm(L)

Surface : 2B, BA, 8K, HL, 2D, Golden 8K, Black 8K etc.

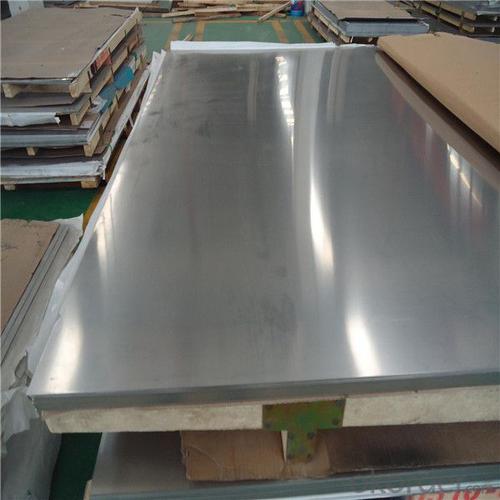

4.Hot rolled stainless steel plate

Thickness : 3.0mm-120mm

Width : 1219mm/1500mm/1800mm/2000mm

Length : 2000mm/2438mm/4000mm/6000mm or cutting randomly

Model size : 3.0mm-120mm(TK)*1219mm(W)*2438mm(L)

3.0mm-120mm(TK )*1500mm(W)*6000mm(L)

3.0mm-120mm(TK) *1800mm(W)*6000mm(L)

3.0mm-120mm(TK) *2000mm(W)*6000mm(L)

Surface : No.1/No.4

5.Characteristics and application

Surface finish | Characteristics and application |

NO.2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

NO.3 | Polished with abrasive belt of git#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

NO.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria,but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators,door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror,kitchen apparatus,ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

- Q: Are stainless steel sheets resistant to galvanic corrosion?

- Yes, stainless steel sheets are highly resistant to galvanic corrosion.

- Q: Are stainless steel sheets suitable for automotive exhaust systems?

- Certainly, stainless steel sheets are indeed appropriate for automotive exhaust systems. Due to their remarkable resistance to corrosion, heat, and vibration, stainless steel is highly sought after as a material for exhaust systems. It possesses the ability to endure the extreme temperatures and harsh conditions that exhaust systems encounter, rendering it a robust and enduring option. Moreover, stainless steel exhibits exceptional thermal conductivity, facilitating the efficient dissipation of heat. Additionally, it provides good formability, granting manufacturers the flexibility to design and mold the exhaust components according to their requirements. All in all, stainless steel sheets emerge as a dependable and widely favored selection for automotive exhaust systems.

- Q: Can stainless steel sheets be used for column covers?

- Yes, stainless steel sheets can be used for column covers.

- Q: Welding defects analysis of 1.5mm stainless steel plate

- UndercutReasons: 1. The welding parameters do not choose U, I is too large, the welding speed is too slow.The arc is too long. The molten metal failed to fill the melting gap in time.Hazard: the working cross section of base metal decreases and the stress concentration at the undercut is concentrated.

- Q: Can stainless steel sheets be cut to size?

- Yes, stainless steel sheets can be cut to size. Stainless steel sheets are versatile materials that can be easily customized to fit specific dimensions and requirements. They can be cut using various methods such as plasma cutting, laser cutting, or waterjet cutting. These processes allow for precise and accurate cuts, ensuring that the stainless steel sheet is cut to the desired size without compromising its integrity. Additionally, stainless steel is known for its durability and resistance to corrosion, making it an excellent choice for applications that require cutting and shaping.

- Q: What are stainless steel sheets?

- Stainless steel sheets are flat metal plates made from an alloy of iron, chromium, and other elements that prevent corrosion and rusting. They are commonly used in various industries such as construction, automotive, and manufacturing, due to their durability, strength, and resistance to staining and oxidation.

- Q: Are stainless steel sheets suitable for railway station platforms?

- Yes, stainless steel sheets are suitable for railway station platforms. Stainless steel is a highly durable material that can withstand heavy foot traffic and extreme weather conditions, making it an ideal choice for platforms in railway stations. It is resistant to corrosion, which is crucial in areas exposed to moisture, such as platforms where rain, snow, or spilled liquids may occur. Stainless steel sheets are also easy to clean and maintain, ensuring a hygienic and safe environment for passengers. Additionally, stainless steel has a sleek and modern appearance, adding to the aesthetic appeal of the railway station. Overall, stainless steel sheets provide the necessary strength, durability, and aesthetic qualities required for railway station platforms.

- Q: Can stainless steel sheets be used for roofing or cladding?

- Yes, stainless steel sheets can be used for roofing or cladding. Stainless steel is a durable and corrosion-resistant material that is well-suited for exterior applications. It offers excellent strength and can withstand harsh weather conditions, making it an ideal choice for roofing or cladding. Additionally, stainless steel has a sleek and modern appearance, which can enhance the aesthetic appeal of a building. Its longevity and low maintenance requirements also make it a cost-effective option in the long run. Overall, stainless steel sheets are a reliable and versatile choice for roofing or cladding projects.

- Q: Are stainless steel sheets suitable for food display cases?

- Indeed, stainless steel sheets are well-suited for food display cases. The food industry extensively employs stainless steel because of its hygienic qualities and lastingness. Its resistance against corrosion, staining, and bacterial proliferation renders it a material of choice for food display cases. Moreover, stainless steel's simplicity in cleaning and upkeep enables a secure and sanitary food display environment. Furthermore, stainless steel's smooth and contemporary aesthetic elevates the presentation of food items, rendering it a favored option for food display cases in establishments like bakeries, delis, and supermarkets.

- Q: What are the advantages of using stainless steel sheets in the aerospace industry?

- There are several advantages of using stainless steel sheets in the aerospace industry. Firstly, stainless steel has excellent corrosion resistance properties, which is crucial in environments with high moisture and temperature fluctuations. This helps to maintain the structural integrity of the aircraft and ensures longevity. Additionally, stainless steel sheets offer high strength-to-weight ratio, making them ideal for constructing lightweight yet durable components. They also possess high heat resistance, allowing them to withstand extreme temperatures that may be encountered during flight. Furthermore, stainless steel sheets can be easily formed and fabricated into complex shapes, providing design flexibility. Overall, these advantages make stainless steel sheets a reliable and efficient choice for various aerospace applications.

Send your message to us

Stainless Steel Sheet 310S hot rolling NO.1

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords