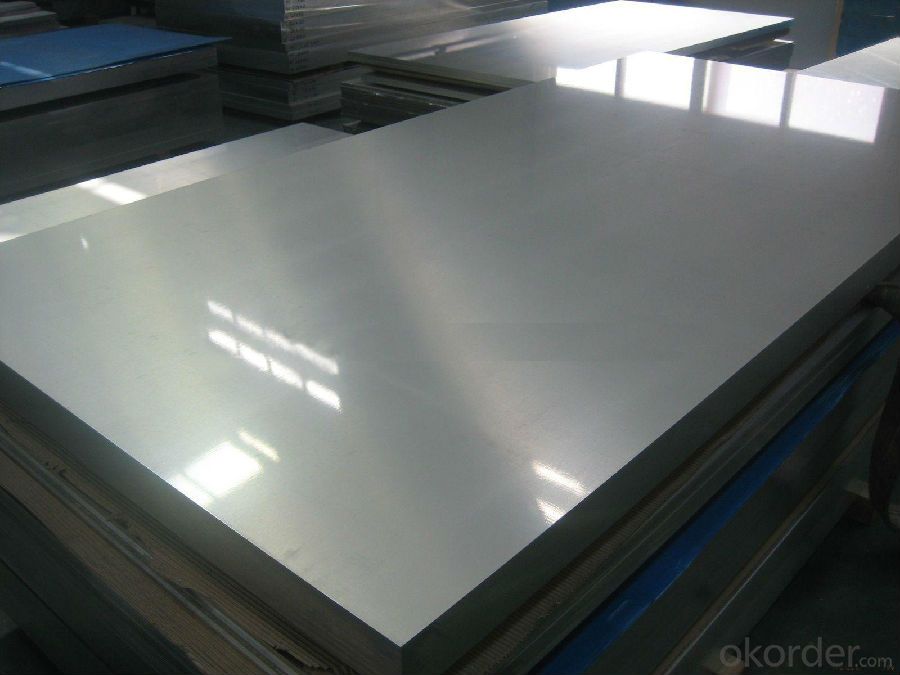

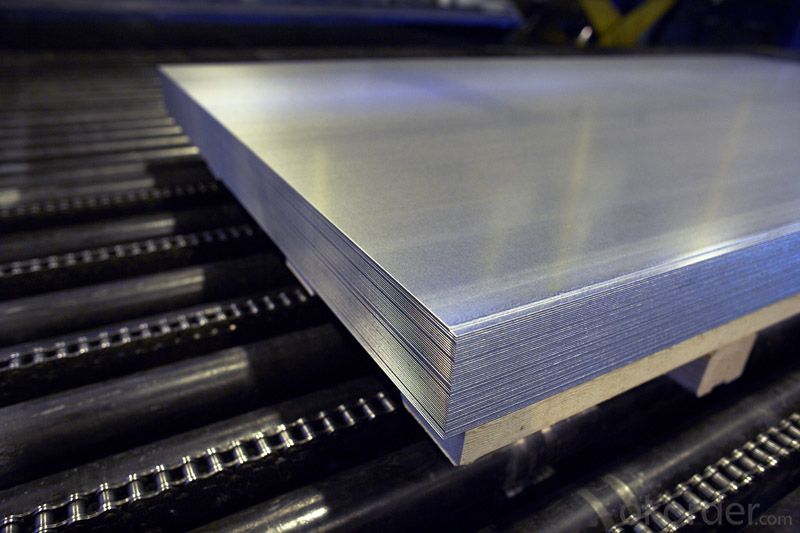

304 Stainless Steel Sheet 304 Stainless Steel Plate 06Cr18Ni9

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

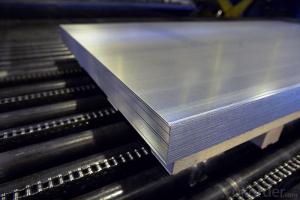

304 Stainless Steel Sheet 304 Stainless Steel Plate 06Cr18Ni9

Packaging Details:Wooden pallets,water proof paper-20'GP or 40'GP for stainless steel sheet.

Delivery Detail:within 5-7 days after receiving the deposit

1. Specifications about stainless steel sheet

Commodity | Professional 430 201 202 304 304l 316 316l 321 310s 309s 904l stainless steel sheet |

Grade | 201,202,304,304L,316,316L,310S,309S,321,301,310,410,420,430,904L |

Brand | TISCO ,BAOSTEEL,POSCO,JISCO,LISCO |

Certification | SGS,BV,IQI,TUV,ISO,etc |

Thickness | 0.2mm-150mm |

Width | 1000,1219,1250,1500mm, or as your requirements |

Length | 2000,2438,2500,3000,6000mm, or as your requirements |

Surface | No.1, 2B, BA, 8K Mirror, Hairline,satin, Embossed,brush,No.4,HL,matt,pvc film,laser film. |

Standard | ASTM,AISI,SUS,JIS,EN,DIN,GB, ASME,etc |

Delivery time | 5-7 days after confirming the order |

MOQ | 1 Ton |

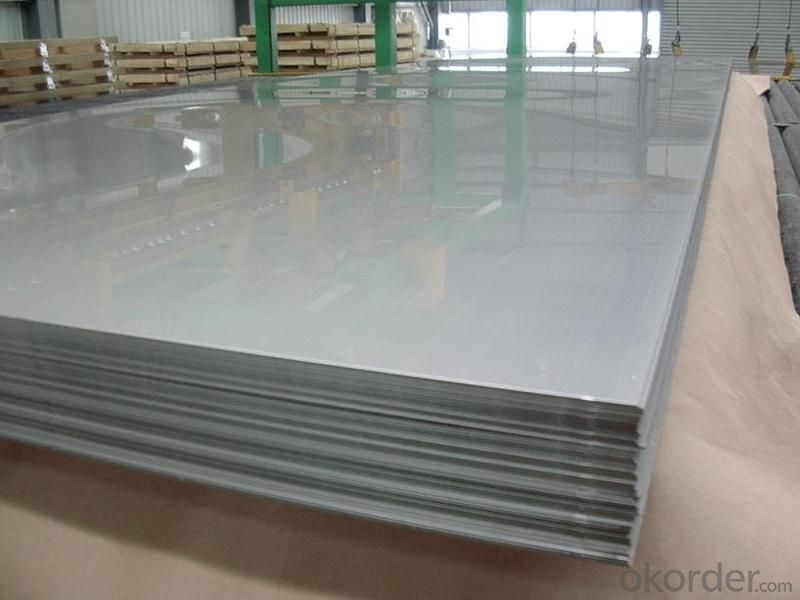

Advantages | Showing the splendor of your quality, wearresistant as well , strong corrosion resistance and decorative effect, durable and beautiful in good taste. |

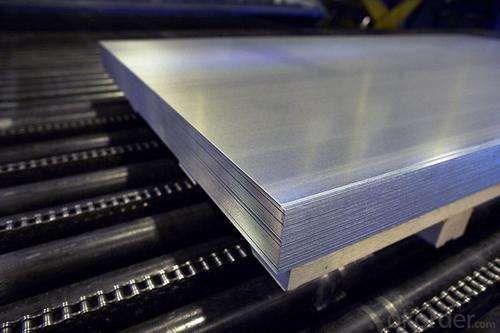

2.Production Flow about stainless steel sheet

Raw materials are sending to hot rolling units for rolling into different sizes

Hot rolled material is annealing in cold; rolled annealing furnace and pickling in acid.

All mill rolls are grinded on precision grinding machine with proper chamfering after first shiftoperation.

All sheets are pickled in different tanks and dried on brush roll machine before dispatched.

These sheets are again annealing and are sent to straighten machine for straightening.

Inspections are done at various stages. Keep proper control overall internal process via rolling,annealin and pickling by our experienced staff.

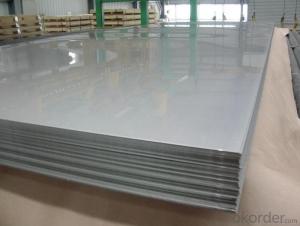

3.Surface--stainless steel sheet

| Surface Finish | Definition | Application |

| 2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

BA/8K mirror | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

| NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

| NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

| Hairline | Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size. | Building Construction. |

| NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

- Q: What are the different types of stainless steel sheet finishes for decorative purposes?

- For decorative purposes, there are several different types of finishes commonly used on stainless steel sheets. These finishes are achieved through various surface treatments and processes, resulting in distinct appearances and textures. Some of the popular finishes include: 1. Brushed or satin finish (No. 4 finish): It is achieved by applying abrasive belts to the surface, creating a smooth, satin-like appearance. This finish is commonly used in architecture and decoration. 2. Mirror finish (No. 8 finish): The surface is polished to a highly reflective mirror-like appearance. It is often used in applications where aesthetics are important, such as wall cladding and decorative elements. 3. Hairline finish: The surface is polished with fine abrasive belts, creating a fine, directional grain pattern. It provides a subtle and elegant look, commonly used in interior design applications. 4. Embossed finish: The stainless steel sheet is pressed with a pattern or texture, creating a three-dimensional surface. This finish is often used in architectural applications, such as wall panels and decorative trim. 5. Bead blasted finish: The surface is blasted with fine glass beads under high pressure, resulting in a uniform, matte appearance. It provides a unique texture and is commonly used in applications where a non-reflective surface is desired. 6. Colored finishes: Stainless steel sheets can also be coated with various colors through processes like PVD or powder coating. These finishes offer a wide range of color options, allowing for more design flexibility. Overall, the choice of stainless steel sheet finish for decorative purposes depends on the desired aesthetic, functionality, and application requirements. Each finish offers its own unique look and feel, providing versatile design possibilities in different industries.

- Q: Can stainless steel sheets be used for decorative room dividers or partitions?

- Decorative room dividers or partitions can indeed utilize stainless steel sheets. This material is renowned for its versatility, endurance, and resistance to corrosion, making it a favored option for various purposes. When employed as room dividers or partitions, stainless steel sheets can infuse a sleek and contemporary vibe into any environment. These sheets can be personalized with diverse finishes, including brushed, mirrored, or patterned, resulting in an exclusive and ornamental appearance. Moreover, stainless steel dividers or partitions are effortlessly cleanable and maintainable, making them a pragmatic selection for bustling areas or commercial settings. All in all, stainless steel sheets offer both practicality and elegance, rendering them suitable for deployment as decorative room dividers or partitions.

- Q: What are the common sizes of stainless steel sheets?

- Common sizes of stainless steel sheets vary depending on the industry and application. However, there are some standard sizes that are readily available in the market. For instance, stainless steel sheets commonly come in thicknesses ranging from 0.4mm to 3.0mm. The most common widths are 1000mm, 1219mm, and 1500mm, while the most common lengths are 2000mm, 2438mm, and 3000mm. These dimensions are often referred to as 4x8 (4 feet by 8 feet), as they are the standard size for stainless steel sheets used in various construction and fabrication projects. It's worth noting that stainless steel sheets can also be custom-cut to specific dimensions based on the requirements of a particular project. This allows for greater flexibility and ensures that the sheets fit perfectly for the intended application.

- Q: Are stainless steel sheets resistant to abrasion?

- Yes, stainless steel sheets are generally resistant to abrasion. Stainless steel is known for its high strength and durability, making it less prone to scratches and wear compared to other materials. It has a smooth surface that can withstand friction and abrasion, making it suitable for various applications where resistance to scratches and wear is required. However, it is important to note that the level of resistance can vary depending on the specific grade and finish of stainless steel used.

- Q: Can stainless steel sheets be used for elevator flooring?

- Yes, stainless steel sheets can be used for elevator flooring. Stainless steel is a durable and corrosion-resistant material, making it suitable for high-traffic areas like elevator floors. Additionally, it provides a sleek and modern appearance, making it a popular choice for elevator interiors.

- Q: Can stainless steel sheets be used for architectural mesh?

- Yes, stainless steel sheets can be used for architectural mesh. Stainless steel is a popular choice for architectural applications due to its durability, strength, and corrosion resistance. It can be fabricated into various mesh patterns, making it suitable for architectural designs such as facades, partitions, and decorative elements.

- Q: How do you remove adhesive residue from stainless steel sheets?

- To remove adhesive residue from stainless steel sheets, you can use various methods such as applying rubbing alcohol, vinegar, or a commercial adhesive remover. Start by soaking a cloth or paper towel in the chosen solution and gently rubbing the residue until it loosens. If needed, use a plastic scraper or your fingertips to carefully scrape off the remaining adhesive. Once all residue is removed, clean the stainless steel surface with warm soapy water and dry it thoroughly.

- Q: Can stainless steel sheets be used in the aerospace industry?

- Yes, stainless steel sheets can be used in the aerospace industry. Stainless steel possesses excellent strength, corrosion resistance, and high-temperature stability, making it suitable for various aerospace applications such as aircraft frames, engine components, and structural parts.

- Q: Can stainless steel sheets be used for food packaging equipment?

- Yes, stainless steel sheets can be used for food packaging equipment. Stainless steel is a popular material choice for food processing and packaging equipment due to its durability, corrosion resistance, and hygienic properties. It is non-reactive, which means it does not interact with the food, ensuring that the quality and taste of the food remain intact. Stainless steel sheets can be easily cleaned and sanitized, making them suitable for use in food packaging equipment where cleanliness and hygiene are of utmost importance. Additionally, stainless steel has a smooth surface, which makes it easy to handle and prevents food particles from sticking to the equipment. Overall, stainless steel sheets are a reliable and safe option for food packaging equipment.

- Q: Are stainless steel sheets good for oil and gas equipment?

- Yes, stainless steel sheets are highly suitable for oil and gas equipment. Stainless steel has excellent corrosion resistance, high strength, and durability, making it an ideal choice for harsh environments and corrosive substances encountered in the oil and gas industry. Additionally, stainless steel's heat resistance and low maintenance requirements further contribute to its effectiveness in this field.

Send your message to us

304 Stainless Steel Sheet 304 Stainless Steel Plate 06Cr18Ni9

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords