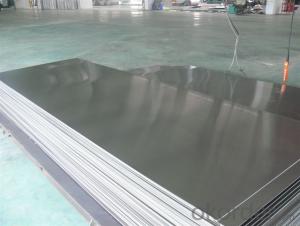

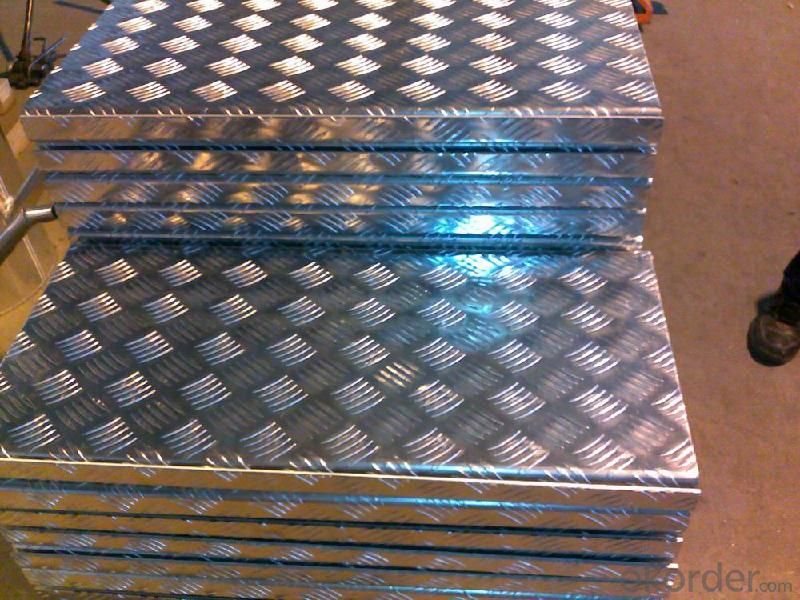

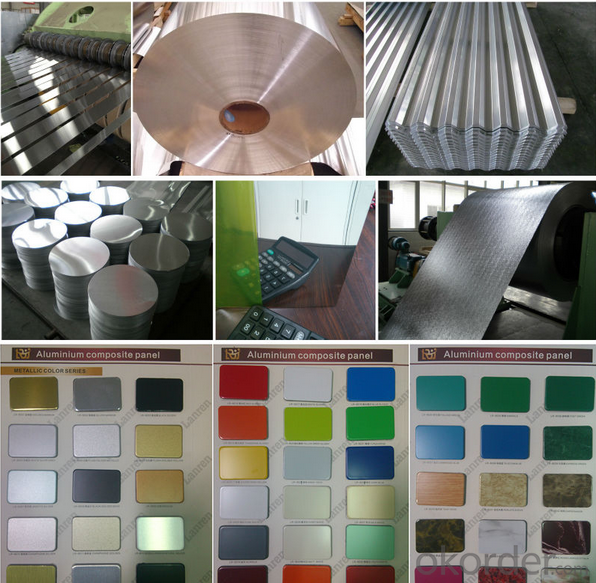

China Thin Aluminum Sheets - 3003 H122 Anti-Slip 3/5 Bars Embossed Diamond Aluminum Plate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description of 3003 H122 Anti-slip 3/5Bars Embossed Diamond Aluminum Plate

Alloy | Temper | Specification(mm) | ||||

Thickness | Width | Length | Embossing Depth | Surface Treatment | ||

1050, 1060, 1100, 1070, 3003, 3105, etc. | O, H12, H14, H16, H18, H22, H24, H26, H32, etc. | 0.25~2.0 | ≤1250 | As per customer’s | 0.08~0.25 | Mill Finish, Bright Finish, Anodized, Color Coated |

Tolerance | ||||||

Thickness (base materials) | Thickness | Embossing Depth | Width | Length | Diagonal | |

0.25~0.5 | 0~0.05 | +/- 0.01 | +/-0.5 | +/- 1.0 | +/- 1.5 | |

> 0.5~2.0 | 0~0.10 | +/- 0.02 | +/-1.0 | +/- 1.5 | +/- 2 | |

We can produce as per customers’ special requirements. | ||||||

Chemical composition of 3003 H122 Anti-slip 3/5Bars Embossed Diamond Aluminum Plate

Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Other | Min Al/ % | ||

Single | Total | ||||||||||||

3003 | 0.6 | 0.7 | 0.05-0.20 | 1.0-1.5 | - | - | - | 0.10 | - | - | 0.05 | 0.15 | Remain |

3004 | 0.3 | 0.7 | 0.25 | 1.0-1.5 | 0.8-1.3 | 0.15 | - | 0.25 | - | - | 0.05 | 0.15 | Remain |

FAQ

--Q: Do you provide free samples?

--A: Yes, free samples will be sent to you on freight at destination.

--Q: Can I get your latest products catalogue?

--A: Yes, it will be sent to you in no time.

--Q: What is the MOQ?

--A: 2 tons

--Q: What are your payment terms?

--A: We accept L/C, T/T.

--Q: What kinds of alloy can you supply?

--A: 1000 series: 1050, 1060, 1070, 1100, 1145, 1200

3000 series: 3003, 3004, 3105, 3104

5000 series: 5052, 5083, 5754, 5182

6000 series: 6061, 6063, 6062, 6063

8000 series: 8011, 8021

--Q: What kinds of temper can you supply?

--A: O-H112: O,H12,H14,H16,H18,H22,H24,H26,H,32,H34,H111,H112

T3, T4, T6

- Q: Are aluminum sheets suitable for marine vessel construction?

- Yes, aluminum sheets are suitable for marine vessel construction. Aluminum is lightweight, strong, and resistant to corrosion, making it an ideal material for building boats and ships. It also offers good thermal conductivity and is easily weldable, making it a popular choice in the marine industry.

- Q: Are aluminum sheets suitable for use in food processing or packaging industries?

- Yes, aluminum sheets are suitable for use in food processing and packaging industries. Aluminum is a versatile and widely used material in the food industry due to its excellent properties and advantages. Firstly, aluminum is a non-toxic material, making it safe for direct contact with food. It does not react with food or alter its taste, ensuring the preservation of the original flavor and quality. This is particularly important in the packaging industry, as it helps to maintain the freshness and integrity of the food product. Secondly, aluminum has excellent thermal conductivity, which allows for efficient and even heat distribution during food processing. This property is beneficial for cooking, baking, and other thermal processes, ensuring that food is cooked or processed evenly. Additionally, aluminum sheets offer excellent barrier properties, such as resistance to moisture, light, and gases. This helps to protect food from external factors that could potentially deteriorate its quality, such as moisture or oxygen. It also helps to prolong the shelf life of packaged food products. Furthermore, aluminum sheets are lightweight, yet strong and durable. This makes them easy to handle and transport in food processing and packaging operations. Their strength and durability ensure that the packaging remains intact and protects the food during transportation and storage. Lastly, aluminum is a sustainable material. It is 100% recyclable, meaning that it can be reused without losing its properties. This helps to reduce the environmental impact and supports the circular economy. In conclusion, aluminum sheets are highly suitable for use in the food processing and packaging industries. Their non-toxic nature, thermal conductivity, barrier properties, lightweight yet strong characteristics, and sustainability make them an ideal choice for ensuring the safety and quality of food products.

- Q: Can aluminum sheets be used in marine environments?

- Yes, aluminum sheets can be used in marine environments. Aluminum is a commonly used material in marine applications due to its excellent corrosion resistance. It forms a protective oxide layer on its surface, which prevents further corrosion in the presence of saltwater or other corrosive elements found in marine environments. Aluminum sheets are lightweight, yet strong, making them ideal for a variety of marine structures such as boat hulls, decks, and superstructures. Additionally, aluminum is highly durable and has a long lifespan, further enhancing its suitability for marine applications.

- Q: Are aluminum sheets suitable for architectural applications?

- Yes, aluminum sheets are highly suitable for architectural applications. Aluminum is known for its lightweight yet strong properties, making it ideal for constructing various architectural elements such as roofing, cladding, windows, doors, and façades. It is corrosion-resistant, durable, and offers excellent thermal and electrical conductivity. Additionally, aluminum can be easily formed, bent, and fabricated, allowing architects to create intricate designs and shapes. Its versatility, aesthetic appeal, and sustainability make aluminum sheets a popular choice in the architectural industry.

- Q: How does the thermal conductivity of aluminum compare to other metals?

- Compared to many other metals, aluminum boasts a relatively high thermal conductivity. It is often hailed as one of the foremost heat conductors among common metals. With a thermal conductivity of approximately 205 watts per meter kelvin (W/m·K), aluminum surpasses copper (about 401 W/m·K) and even silver (about 429 W/m·K). As a result, aluminum excels at efficiently transferring heat, making it a widely favored option for heat sinks, radiators, and various applications necessitating effective heat dissipation. Nonetheless, it is worth mentioning that certain metals, such as diamond and graphene, surpass aluminum in terms of thermal conductivity.

- Q: Status of aluminum sheet F

- H is the hardening state, should be followed by a digital representation of what the work hardening and degree of hardness, suitable to improve the strength of the product through the hardening product in hardening after after (or not after) additional heat treatment makes the strength decreased.The status of aluminum sheet is basically divided into five kinds, in addition to the above three kinds, there are two kinds of W and T:W solid fusion heat treatment state, an unstable state, is only applicable to naturally aged alloy at room temperature after solid solution heat treatment.

- Q: I have seen some stainless steel rifles that you can basically dunk in water, require no cleaning, etc and perform time after time. If SS is so good why are most weapons made of aluminum parts which is then anodized coated black? If you dunk these weapons in water will they rust? Thanks

- You may pick up as much as three or four MPH with a stainless prop. The reason is that aluminum props will flex a bit under power and decrease the pitch where SS props won't. The downside of a stainless prop is that if you hit something solid at speed, you will likely tear out your lower unit. I have owned a bunch of boats and never put a SS prop on any of them. It just wasn't worth the chance for that potential big repair bill. My advice? Have your aluminum prop rebuilt. It's fairly economical.

- Q: Are aluminum sheets suitable for electronic components?

- Yes, aluminum sheets are suitable for electronic components. Aluminum is commonly used in the production of electronic components due to its excellent conductive properties, lightweight nature, and high thermal conductivity. It is often utilized in circuit boards, heat sinks, and enclosures for electronic devices.

- Q: What are the different types of coatings applied to aluminum sheet?

- There are several different types of coatings that can be applied to aluminum sheet, each with its own unique properties and benefits. Some of the most common types of coatings include: 1. Anodizing: This is an electrochemical process that forms a protective layer of aluminum oxide on the surface of the sheet. Anodizing provides excellent corrosion resistance and enhances the appearance of the aluminum by creating a durable, colorful finish. 2. Powder Coating: In this process, a dry powder is electrostatically applied to the aluminum sheet and then cured under heat to form a hard, protective coating. Powder coating offers excellent durability, resistance to chipping and scratching, and a wide range of colors and finishes. 3. Paint: Aluminum sheet can also be coated with paint, which provides both aesthetic and protective benefits. The paint can be applied in liquid form and then cured under heat to form a strong, durable coating. Paint coatings offer a wide range of colors and finishes, allowing for customization and design flexibility. 4. Laminating: Laminating involves applying a thin layer of protective film or laminate to the surface of the aluminum sheet. This coating provides additional protection against scratches, abrasion, and UV damage, while also enhancing the appearance of the sheet. 5. Conversion Coatings: Conversion coatings are chemical treatments that convert the surface of the aluminum sheet into a more corrosion-resistant compound. Common conversion coatings include chromate conversion coatings and phosphating, which provide a protective layer that improves adhesion of subsequent coatings. 6. Clear Coatings: Clear coatings, such as lacquer or clear powder coat, can be applied to aluminum sheet to provide protection against oxidation and corrosion while preserving the natural appearance of the metal. Clear coatings are often used when the goal is to maintain the metallic look of the aluminum. These are just a few examples of the different types of coatings that can be applied to aluminum sheet. The choice of coating will depend on factors such as the desired appearance, level of protection required, and the specific application of the aluminum sheet.

- Q: Can aluminum sheets be used for reflective insulation?

- Yes, aluminum sheets can be used for reflective insulation. Aluminum is highly reflective and has good thermal conductivity, making it an excellent choice for reflecting heat and reducing heat transfer. When used as insulation, aluminum sheets can reflect heat away from the surface, preventing it from entering or escaping the desired area. This can help in maintaining a comfortable temperature inside a building or protecting sensitive equipment from extreme heat or cold. Additionally, aluminum sheets are lightweight and easy to install, making them a popular choice for reflective insulation applications.

Send your message to us

China Thin Aluminum Sheets - 3003 H122 Anti-Slip 3/5 Bars Embossed Diamond Aluminum Plate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords