Bronze Anodized 3000 Series Stucco Embossed Aluminum Coils for Refrigerator

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Specifications of 3000 Series Stucco Embossed Aluminum Coils for Refrigater

Alloy:1060 1050 1100 1200 3003

Temper: O H12 H14 H16 H18 H24

Thickness(mm):0.2-10mm

Width(mm):30-2300

Length(mm):800-13000

Packing: wooden/veneer pallet, wooden/veneer case

Unit Price/Payment: FOB, CIF, CFR

Payment term: TT, LC

MOQ: 2.0-2.5 metric ton per size

2. Application of 3000 Series Stucco Embossed Aluminum Coils for Refrigater

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of 3000 Series Stucco Embossed Aluminum Coils for Refrigater

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

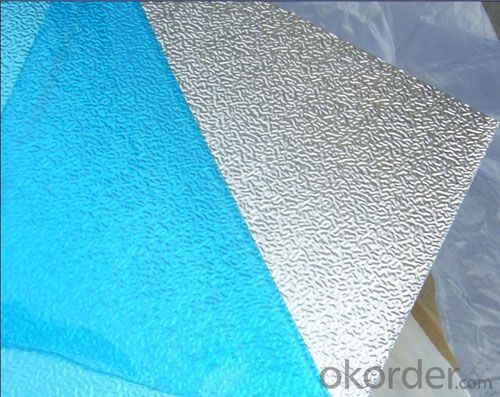

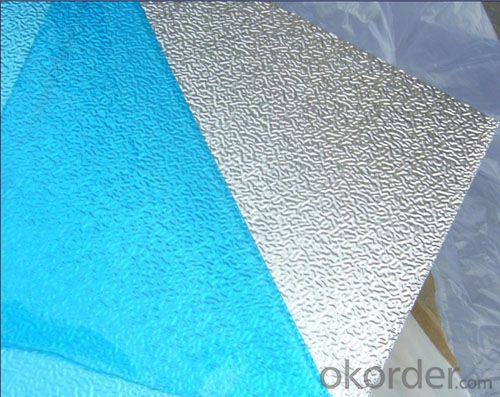

5. Image of 3000 Series Stucco Embossed Aluminum Coils for Refrigater

6. FAQ

1) What is your delivery time?

Our regular production time is over 30 days, It depends on the order quantity also.

2) What is your payment term?

We accept T/T, LC at sight, Usance LC 30, 60, 90, 120, 180 DAYS.

3) What is your price structure?

Our foil price is based on Shanghai Metal Price(SMM), not LME, but we could offer LME+ Conversion for your reference.

4) What is your Delivery term?

We do FOB, CFR, CIF, we don't do DDP.

5) Could you offer sample?

We could offer sample as your requirement. A4 Size sample is free for you, for bigger roll sample, it depends on the coil weight.

- Q: This question asks about the various types of aluminum sheets that are commonly used for roofing purposes, including their specific applications and characteristics.

- <p>Aluminum sheets used for roofing come in various types, each with unique properties and applications. The main types include: 1) Corrugated Aluminum Sheets: Known for their strength and durability, these are often used in commercial and industrial roofing due to their ability to withstand harsh weather conditions. 2) Standing Seam Aluminum Sheets: These provide a sleek, clean look and are favored for their water-resistant properties, making them ideal for residential and architectural applications. 3) Flat Aluminum Sheets: Offer a smooth surface finish and are used where a uniform appearance is desired. 4) Perforated Aluminum Sheets: These have small holes that allow for ventilation, reducing heat build-up and are used in areas requiring natural light and air circulation. 5) Embossed Aluminum Sheets: With a textured surface, they provide added rigidity and are used in both residential and commercial settings for their aesthetic appeal. Each type is chosen based on the specific needs of the roofing project, such as design, weather resistance, and longevity.</p>

- Q: Using thin copper sheets and thin aluminum sheets, respectively, from heat source heat conduction to aluminum heat sink, which kind of efficiency is higher?

- The key is not copper or aluminum, the heat transfer coefficient between the heat source and the heat sink is more important to the overall heat dissipation effect.In theory, copper is good, but copper is relatively expensive and heat dissipation is a little too high.

- Q: This question asks for the steps to take in order to accurately measure the dimensions of an aluminum sheet before purchasing one.

- <p>To measure the dimensions of an aluminum sheet for purchase, first, ensure you have a measuring tape or a ruler. Measure the length and width of the sheet from one corner to the opposite corner, making sure to measure along the longest and widest sides. Record these measurements in the same unit of measurement used by the supplier (commonly inches or centimeters). If the sheet is not a perfect rectangle, measure the diagonal to confirm the dimensions. Note any irregularities or variations in thickness that might affect the intended use. Once you have these measurements, compare them with the available options from the supplier to select the appropriate size.</p>

- Q: Can aluminum sheet be used for reflective surfaces?

- Yes, aluminum sheet can be used for reflective surfaces.

- Q: What are the advantages of using aluminum sheets in automotive applications?

- Using aluminum sheets in automotive applications offers several advantages. Firstly, aluminum is a lightweight material, meaning it can significantly reduce the vehicle's overall weight, leading to improved fuel efficiency and lower emissions. This is crucial in today's environmentally conscious society. Secondly, aluminum sheets provide excellent corrosion resistance due to their oxide layer. This makes aluminum a durable choice for automotive applications, ensuring the vehicle maintains its structural integrity and aesthetic appeal over time. Additionally, aluminum has exceptional thermal conductivity, allowing for efficient heat dissipation. This makes it suitable for applications such as radiators and heat exchangers, preventing overheating and extending the lifespan of various vehicle components. Moreover, aluminum is highly malleable, allowing it to be easily formed into complex shapes and designs. This versatility enables greater design flexibility in automotive manufacturing, resulting in sleek and aerodynamic vehicles. Furthermore, aluminum is a recyclable material, aligning with the industry's focus on sustainability. Its recyclability contributes to a more circular economy, where materials can be reused and repurposed, reducing waste and minimizing environmental impact. Lastly, despite being lightweight, aluminum sheets have an excellent strength-to-weight ratio. This robustness allows for the construction of safe and reliable vehicles capable of withstanding various road conditions and potential impacts. In conclusion, the benefits of using aluminum sheets in automotive applications include weight reduction, corrosion resistance, thermal conductivity, design flexibility, recyclability, and a high strength-to-weight ratio. These advantages contribute to improved fuel efficiency, durability, safety, and environmental sustainability in the automotive industry.

- Q: is there any kind of deoderant, other than those crystals that smell, that don't have aluminum in it?

- yes, just look for the word 'deodorant' instead of 'anti-perspirent'. I understand you may be concerned about the aluminum causing harm - however, it is the only way to stay 'dry'. The others allow you to sweat, and just cover up the odor.

- Q: What types of aluminum sheets are recommended for outdoor applications due to their durability and resistance to weather conditions?

- <p>Yes, there are specific types of aluminum sheets designed for outdoor use. Marine-grade aluminum sheets, such as 5083 or 5086 alloys, are highly resistant to corrosion and are ideal for marine applications. Aluminum sheets with a protective coating, like anodized aluminum or those with a fluoropolymer finish, offer excellent weather resistance and durability. Additionally, aluminum sheets with a mill finish or those coated with a clear coating can also be suitable for outdoor use due to their resistance to UV rays and ability to withstand temperature fluctuations.</p>

- Q: I did electrolysis by adding aluminum to the ends of the wire. I waited about 2 hours, and then I filtered the water. After it dried, I was left with powder. It's gray.It that aluminum powder or something else? I'm making thermite, if its not aluminum powder will it still work?

- Kinda sorta, the problem with this is that all you did was made aluminium oxide or hydroxide, when you electrolyzed the aluminium you also electrolyzed a bit of water with it, which added a hydroxyl group to the aluminum, which may have dropped a hydrogen when you dried it. If you could find an aluminium compound that is water soluble (DAMNED HARD to find) you could electrolyze it in water to get aluminium dust in the water, but that isnt very reliable or economical, the best thing for you to do is to get a ball mill or rock tumbler, add aluminium fold and about half full of regular marbles, let it run for 3 or so weeks. You need it really fine!

- Q: Are the aluminum sheets suitable for manufacturing heat exchanger tubes?

- Yes, aluminum sheets are suitable for manufacturing heat exchanger tubes. Aluminum has excellent thermal conductivity, corrosion resistance, and is lightweight, making it an ideal material for heat transfer applications.

- Q: Can aluminum sheets be painted or coated?

- Yes, aluminum sheets can be painted or coated. Aluminum is a versatile material that can be easily painted or coated to enhance its appearance or improve its performance. The key to achieving a successful paint or coating on aluminum is proper surface preparation and the use of suitable primers or coatings designed specifically for use on aluminum. The surface of the aluminum sheet needs to be clean, free from any oils, dirt, or oxidation, and may require sanding or etching to promote adhesion. Once the surface is prepared, a wide range of paints or coatings can be applied, including liquid paints, powder coatings, and anodizing. These finishes can provide various benefits such as increased corrosion resistance, improved durability, enhanced aesthetics, and even specialized properties like heat resistance or anti-microbial properties. It is important to consult with a professional or follow the manufacturer's guidelines to ensure the proper application and longevity of the paint or coating on aluminum sheets.

Send your message to us

Bronze Anodized 3000 Series Stucco Embossed Aluminum Coils for Refrigerator

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords