Aluminum Bronze Color Coating Aluminium Coil AA3003 for Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Color Coating Aluminium Coil AA3003 for Decoration

characteristics | Application |

1) Super peeling strength | 1) Building exterior curtain walls |

2) Excellent surface flatness and smoothness | 2) Decoration and renovation additions for old buildings |

3) Superior weather, corrosion, pollutant resistance | 3) Decoration of interior walls, ceilings, bathrooms, kitchens and balconies |

4) Even coating, various colors | 4) Shop door decorations |

5) Fireproof, excellent heat and sound insulation | 5) Advertisement board display platforms and signboards |

6) Superior impact resistance | 6) Wallboards and ceilings for tunnels |

7) Lightweight and easy to process | 7) Industrial materials, materials for vehicles and boats |

2. Application of Color Coating Aluminium Coil AA3003 for Decoration

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels, column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Color Coating Aluminium Coil AA3003 for Decoration

• Our goods quality is top, the surface is smooth, and every steel coil

• No Joint, No Bends, no spots, no roller marks.

• MTC will be provided with goods, third part inspection is acceptable, for example, SGS, BV. Etc

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

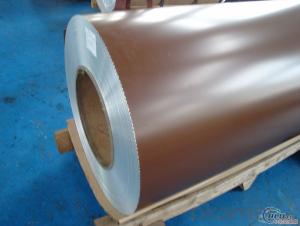

5. Image of Color Coating Aluminium Coil AA3003 for Decoration

6. Package and shipping of Color Coating Aluminium Coil AA3003 for Decoration

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Is it appropriate to use a wire brush for cleaning an aluminum coil?

- <p>Using a wire brush to clean an aluminum coil is not recommended. Wire brushes can cause scratches and damage the surface of the aluminum, which can lead to corrosion over time. Instead, use a soft cloth or sponge with a mild cleaning solution to gently clean the coil. This will prevent any damage to the aluminum while effectively removing dirt and debris.</p>

- Q: This question asks for the method to calculate the volume of an aluminum coil given its size.

- <p>To calculate the volume of an aluminum coil, you need to know its dimensions: the length of the coil, the diameter of the wire, and the number of turns. The volume can be calculated using the formula for the volume of a cylinder, adjusted for the coil's shape. The formula is: Volume = 蟺 * (diameter/2)^2 * length * number of turns. Here, 蟺 is approximately 3.14159, diameter is the diameter of the wire in the coil, length is the total length of the coil, and the number of turns is the number of times the wire is wound around the coil. This formula gives you the total volume of the aluminum in the coil.</p>

- Q: This question asks for an explanation of the various materials used for coating aluminum coils.

- <p>Aluminum coil coating materials can be categorized into several types, including: 1. Organic coatings, such as polyester, acrylic, and polyvinylidene fluoride (PVDF), which offer good weather resistance and color stability. 2. Inorganic coatings, like fluoropolymers, which provide exceptional chemical resistance and high-temperature stability. 3. Metal coatings, such as zinc or other metals, used for enhanced corrosion resistance. 4. Ceramic coatings, which are known for their high durability and resistance to heat and chemicals. 5. Laminates, which combine multiple materials for specific performance characteristics. These coatings are chosen based on the intended application of the aluminum coil, such as in construction, automotive, or packaging industries.</p>

- Q: Are aluminum coils available in different colors?

- Yes, aluminum coils are available in different colors. The process of coloring aluminum coils involves coating the surface with a durable finish that can be in various colors. This coating is typically achieved through a process called coil coating, where the aluminum coil is cleaned, pre-treated, and then coated with a layer of paint or other colored material. This allows for a wide range of colors to be applied to the aluminum coils, providing flexibility in design and aesthetic options for various applications.

- Q: This question asks for a comparison of the benefits and drawbacks of utilizing aluminum coil in insulation applications.

- <p>Aluminum coil has several advantages for insulation, including its high thermal conductivity, which allows for efficient heat transfer, and its lightweight nature, making it easy to handle and install. It also offers good resistance to corrosion and is cost-effective compared to other materials. However, it has some disadvantages such as low strength, which may require additional support structures, and it can be prone to denting or damage if not handled carefully. Additionally, aluminum's high conductivity can lead to increased heat loss if not properly insulated, and it may require more frequent maintenance due to its susceptibility to environmental factors.</p>

- Q: Are there any limitations to the maximum coil length of aluminum coils?

- Yes, there are limitations to the maximum coil length of aluminum coils. The length of aluminum coils is typically restricted by factors such as the capabilities of manufacturing equipment, transportation constraints, and handling limitations. Additionally, longer coils are more prone to issues like coil sagging and deformation during storage or handling. Therefore, there is a practical limit to the maximum coil length that can be produced and effectively utilized in various industries.

- Q: How are aluminum coils processed for specific applications?

- Aluminum coils undergo a series of processes to tailor them for specific applications. The first step is the selection of high-quality aluminum alloy, which determines the coil's properties. Once the alloy is chosen, it is melted and cast into large ingots. After cooling, the ingots are rolled between heavy rollers to reduce their thickness and form long, continuous aluminum coils. Next, the coils are subjected to various surface treatments to enhance their performance and appearance. One common treatment is cleaning, which removes any impurities or contaminants from the coil's surface. This is typically done through chemical or mechanical methods. Another treatment is chemically etching the surface to create a specific texture or pattern, which can improve adhesion or aesthetics. To further enhance the coil's properties, it may undergo processes like heat treatment or annealing. Heat treatment involves heating the coil to a specific temperature and then rapidly cooling it to modify its mechanical or physical properties. Annealing, on the other hand, involves heating the coil to a predetermined temperature and then slowly cooling it to relieve internal stresses and improve its ductility. Coils destined for specific applications may also undergo additional processes. For instance, if the coil is intended for use in the automotive industry, it may be subjected to lubrication or coating processes to reduce friction or improve corrosion resistance. If it is meant for electrical applications, it might undergo surface treatments to enhance its conductivity or insulation properties. Finally, the coils are usually cut into desired lengths and packaged for transportation. This can be done through various methods like slitting, shearing, or sawing, depending on the application and customer requirements. Overall, the processing of aluminum coils for specific applications involves a combination of casting, rolling, surface treatment, heat treatment, and additional processes to enhance their performance, appearance, and suitability for their intended use.

- Q: Is it possible to use an electric stove with an aluminum coil heater?

- <p>Yes, you can use an electric stove with an aluminum coil heater. However, it's important to ensure that the aluminum coil heater is designed for use with an electric stove. Aluminum is a good conductor of heat and can be used in heating elements. Make sure the heater is compatible with the stove's power requirements and that it's installed correctly to avoid any safety hazards. Always follow the manufacturer's instructions for installation and use.</p>

- Q: How are aluminum coils manufactured to specific dimensions?

- Aluminum coils are manufactured to specific dimensions through a series of processes that involve precision engineering and cutting-edge technology. The process starts with the selection of high-quality aluminum ingots, which are then melted and cast into long, flat strips. Once the aluminum is in the form of flat strips, it undergoes a series of rolling operations. The strips are passed through a rolling mill, where they are progressively reduced in thickness and elongated in length. This rolling process helps in achieving the desired dimensions and thickness for the coils. After the initial rolling, the strips are subjected to a process called annealing. Annealing involves heating the aluminum to a specific temperature and then cooling it slowly. This process helps in improving the ductility and reducing the internal stresses in the metal, making it easier to work with in subsequent manufacturing steps. The next step is slitting, where the wide strip is cut into narrower strips of the desired width. This is done using high-precision slitting machines that ensure accurate and consistent dimensions for each coil. The slitting process also involves edge trimming to remove any irregularities and ensure straight edges. Once the narrower strips are obtained, they are coiled using specialized machines. These machines carefully wind the strips into coils of the desired size and shape. The coiling process ensures that the aluminum is tightly wound and securely held in place. To further enhance the dimensional accuracy, the coils may undergo a final leveling process. This involves passing the coils through a leveling machine that applies pressure to flatten any irregularities or distortions in the metal, ensuring a uniform and consistent thickness. Overall, the manufacturing of aluminum coils to specific dimensions requires a combination of precision rolling, slitting, coiling, and leveling processes. These processes, along with advanced machinery and quality control measures, ensure that the final product meets the exact specifications required by the customer.

- Q: What are the different types of aluminum coils available in the market?

- There are several different types of aluminum coils available in the market, each with its own unique characteristics and applications. 1. Plain Aluminum Coils: These are basic aluminum coils that are typically used for general applications. They have a smooth surface and are often used in construction, automotive, and packaging industries. 2. Color Coated Aluminum Coils: These coils are coated with a layer of paint or other finishes to enhance their aesthetic appeal and provide additional protection against corrosion. They are commonly used in the manufacturing of building facades, signage, and decorative applications. 3. Embossed Aluminum Coils: These coils have a textured or patterned surface, which gives them a decorative and non-slip finish. They are often used in applications where aesthetics and functionality are important, such as flooring, staircases, and decorative panels. 4. Anodized Aluminum Coils: These coils undergo an anodizing process, where a protective oxide layer is formed on the surface of the aluminum. This enhances their corrosion resistance and makes them suitable for outdoor applications, such as architectural elements, electronic components, and aerospace industry. 5. Pre-painted Aluminum Coils: These coils come with a pre-applied paint coating, which eliminates the need for additional painting or finishing. They are commonly used in industries that require high-quality, durable, and color-consistent products, such as automotive, appliances, and electronics. 6. Heat Exchanger Aluminum Coils: These coils are specifically designed for heat transfer applications, such as air conditioning and refrigeration systems. They have a high thermal conductivity and are often made from alloy grades that offer excellent corrosion resistance in harsh environments. It is important to consider the specific requirements and intended use of the aluminum coil before making a purchase. This will help ensure that the appropriate type of coil is selected for the desired application, thereby optimizing performance and longevity.

Send your message to us

Aluminum Bronze Color Coating Aluminium Coil AA3003 for Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords