Stucco Embossed Aluminum Coil for High Performance Refrigeration Aluminum Condenser Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Refrigeration Aluminum Condenser Coil Description:

They are widely used in construction and decoration, hardware and electric appliances manufacture,

automobile manufacture and other industrial and civil purposes, such as electronic capacitor, rice

cooker, refrigerator, computer casting, lamp shade, air-conditioner, cosmetics cover and box, air-

conditioner radiator, inner container of disinfecting cabinet, ceiling board, automobile motherboard,

cover board and top board, etc.

2.Main Features of Refrigeration Aluminum Condenser Coil :

1). The heat exchangers have a wide rang of plications such as: Window, Split and package AC systems;

2). Commercial Refrigeration Systems (Kitchen refrigerator, bottle cooler, deep freezer, milk tank, etc);

3). Industrial Refrigeration Systems (Printing machine, Colling machine, etc);

4). Automobile-Buses / Car air conditioning;

5). Railway air-conditioning an Marine air-conditioning;

6). Special Application Coils.

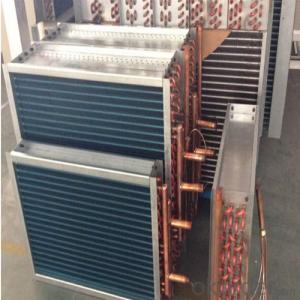

3. Refrigeration Aluminum Condenser Coil Images:

4. Refrigeration Aluminum Condenser Coil Specification:

| Fin Pattern | Copper Tube O. D. (mm) | Row Space(mm) | Hole Space(mm) | Fin Thickness(mm) | Fin Space(mm) | ||||

| Flat fin | Sine wave with blade fin | Smooth sine wave fin | Window fin | Sesamoid fin | |||||

| A | 7 | 12.7 | 21 | 0.105 | / | / | 1.3 | 1.3 | / |

| B | 7 | 13.2 | 17.6 | 0.105 | / | / | 1.3 | 1.3 | / |

| C | 7 | 12.7 | 20.4 | 0.105 | / | / | 1.3~1.8 | 1.3~1.8 | / |

| D | 7.94 | 15.88 | 25.4 | 0.105 | 1.8~3.0 | 1.8~3.0 | 1.8~3.0 | 1.8~3.0 | / |

| E | 9.52 | 22 | 25.4 | 0.105~0.15 | 1.6~3.2 | 1.6~3.2 | 1.6~3.2 | 1.6~3.2 | / |

| F | 9.52 | 22 | 25.4 | 0.18~0.4 | 3.5~6.35 | / | / | / | / |

| G | 9.52 | 21.65 | 25 | 0.105~0.18 | 1.6~3.2 | 1.6~3.2 | 1.6~3.2 | 1.6~3.2 | / |

| H | 9.52 | 21.65 | 25 | 0.15~0.24 | 3.2~6.35 | 3.2~6.35 | 3.2~6.35 | / | / |

| I | 12.75 | 27.5 | 31.75 | 0.115~0.15 | 1.5~3.5 | 1.5~3.5 | 1.5~3.5 | 1.5~3.5 | 1.6~3.2 |

| J | 15.88 | 33 | 38.1 | 0.115~0.15 | 1.5~4.0 | 1.5~4.0 | 1.5~4.0 | / | / |

| K | 15.88 | 34.64 | 40 | 0.115~0.15 | / | 2.6~3.5 | 2.6~3.5 | / | / |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: What are the potential applications of embossed aluminum coils?

- Embossed aluminum coils have a wide range of potential applications due to their unique properties and versatility. Some of the potential applications of embossed aluminum coils include: 1. Decorative purposes: Embossed aluminum coils are commonly used in interior and exterior architectural design applications. They can be used for wall cladding, ceiling panels, decorative facades, and other decorative elements. The embossed patterns on the coils add a visually appealing texture and depth to the surfaces, enhancing the overall aesthetic appeal of the space. 2. Packaging industry: Embossed aluminum coils are widely used in the packaging industry. They can be used for manufacturing packaging materials such as cans, boxes, lids, and closures. The embossed patterns on the coils not only enhance the visual appeal of the packaging but also provide additional strength and rigidity to the structure, making it more durable and resistant to damage. 3. Heat transfer applications: Embossed aluminum coils are also used in heat transfer applications. The embossed patterns on the coils create turbulence in the fluid flow, increasing the heat transfer efficiency. This makes them suitable for use in heat exchangers, evaporators, condensers, and other heat transfer equipment. 4. Automotive industry: Embossed aluminum coils find applications in the automotive industry. They are used in the manufacturing of car body panels, trims, and decorative elements. The embossed patterns on the coils can provide a unique and stylish appearance to the vehicles, making them stand out in the crowd. 5. Electrical industry: Embossed aluminum coils are commonly used in the electrical industry for various applications. They can be used for manufacturing electrical enclosures, switchboards, and control panels. The embossed patterns on the coils improve the structural integrity and provide better protection against external factors such as moisture, dust, and corrosion. 6. Furniture industry: Embossed aluminum coils are also used in the furniture industry. They can be used for manufacturing furniture components such as table tops, cabinet doors, and decorative trims. The embossed patterns on the coils add a touch of elegance and sophistication to the furniture, making it visually appealing. Overall, embossed aluminum coils have a wide range of potential applications in various industries, including architecture, packaging, heat transfer, automotive, electrical, and furniture. Their unique properties and versatility make them a preferred choice for many applications where aesthetics, strength, and durability are important.

- Q: Can aluminum coils be used for pharmaceutical packaging?

- Certainly, pharmaceutical packaging can make use of aluminum coils. Aluminum is widely preferred for such purposes owing to its numerous advantageous properties. Notably, its lightweight nature, resistance to corrosion, and exceptional barrier properties render it exceptionally suitable for safeguarding pharmaceutical items against external elements like moisture, oxygen, and light. Moreover, aluminum coils can be conveniently fashioned into various shapes and sizes, thereby offering flexibility to meet diverse packaging requirements. It is also worth mentioning that aluminum is both non-toxic and non-reactive, thereby guaranteeing the safety and overall quality of pharmaceutical products.

- Q: What is the typical hardness of aluminum coils?

- The hardness of aluminum coils can vary depending on different factors, such as the composition of the alloy, the process of tempering, and the intended use. Manufacturers produce aluminum coils with different levels of hardness to meet various needs and requirements. Aluminum coils are available in different tempers, including soft, half-hard, and full-hard. Soft aluminum coils have low hardness and are highly malleable, making them suitable for applications that require easy shaping, such as packaging and wrapping materials. Half-hard aluminum coils are moderately hardened and offer a balance between formability and strength, making them suitable for applications like roofing and siding. Full-hard aluminum coils have the highest hardness and provide excellent strength, making them ideal for applications that require structural integrity, such as automotive parts and construction materials. To determine the specific hardness of aluminum coils, various testing methods can be used, such as Rockwell hardness, Vickers hardness, or Brinell hardness. These tests measure the resistance of the aluminum surface to indentation and provide a numerical value indicating the material's hardness. However, it is important to consult the manufacturer or supplier for the specific hardness values, as they can vary depending on the specific alloy and temper of the aluminum coil.

- Q: Can aluminum coils be used in the production of consumer electronics?

- Yes, aluminum coils can be used in the production of consumer electronics. Aluminum coils are commonly used in various electronic devices, such as smartphones, laptops, and televisions, due to their lightweight, high conductivity, and thermal efficiency properties. They are used in components like heat sinks, connectors, and circuit boards to ensure efficient heat dissipation and electrical conductivity, thereby enhancing the performance and reliability of consumer electronics.

- Q: Can aluminum coils be used in the production of solar panels?

- Yes, aluminum coils can be used in the production of solar panels. Aluminum is a lightweight and durable material that offers various benefits for solar panel manufacturing. It is highly conductive and has excellent thermal properties, allowing for efficient heat dissipation. Additionally, aluminum is resistant to corrosion, which is crucial for solar panels as they are exposed to various weather conditions. Moreover, aluminum is a cost-effective material, making it a popular choice in the solar industry. Overall, using aluminum coils in the production of solar panels helps to enhance their performance, longevity, and cost-effectiveness.

- Q: im melting aluminum and what should i use for metal. cans will just oxygenize( i forget the word for it sorry)

- aluminum, in general, will just oxidize if heated in air. it is not just cans that behave that way when they (alcan, alcoa) smelt aluminum industrially they keep it in a reducing environment and do not allow molten aluminum to contact air. so use any aluminum you like but prevent it from contacting air.

- Q: This question asks for methods to clean an aluminum coil, which involves understanding the appropriate cleaning materials and techniques to avoid damaging the aluminum.

- <p>To clean an aluminum coil, start by using a soft cloth or sponge dampened with warm water and mild dish soap. Gently wipe the coil to remove dirt and grime. Avoid abrasive materials or harsh chemicals that could scratch the surface. After cleaning, rinse the coil thoroughly with clean water to remove any soap residue. Dry the coil completely to prevent water spots or corrosion. For stubborn stains, consider using a specialized aluminum cleaner, but always follow the manufacturer's instructions and test on a small area first.</p>

- Q: How are aluminum coils stored in a warehouse?

- Aluminum coils are commonly kept in a warehouse to guarantee their safety and easy accessibility. Depending on the available space and coil weight, they are typically arranged in rows either vertically or horizontally. To maintain their shape and prevent any harm, pallets or racks are often used to provide support and stability. Additionally, protective materials like shrink wrap or plastic sheets can be wrapped around the coils to shield them from dust, moisture, and other potential dangers. Proper labeling and organization are also essential for efficient inventory management and easy retrieval. Ultimately, the objective of storing aluminum coils in a warehouse is to make the most of the space, minimize the risk of damage, and ensure they are ready for shipment or further processing.

- Q: A certain ionic compound is made entirely of aluminum and oxygenWhat is the formula for this compound?

- Aluminum Oxide Al2O3

- Q: How are aluminum coils used in the production of marine vessels?

- Aluminum coils are extensively used in the production of marine vessels due to their unique properties and advantages. Firstly, aluminum is a lightweight material compared to other metals commonly used in shipbuilding such as steel. This characteristic makes it ideal for constructing marine vessels as it reduces the overall weight of the ship, allowing it to float more easily in water. The use of aluminum coils in the construction process ensures that the vessel remains buoyant without compromising its structural integrity. Secondly, aluminum is highly corrosion-resistant, especially when exposed to saltwater environments. Marine vessels are constantly exposed to water, which can be corrosive and damaging to metal components. By using aluminum coils, shipbuilders can minimize the risk of corrosion and increase the longevity of the vessel. Moreover, aluminum coils offer excellent thermal conductivity. This property is crucial in marine vessels as it helps dissipate heat generated by engines, machinery, and equipment, ensuring that the ship operates efficiently and safely. Additionally, aluminum coils can be easily formed, shaped, and welded, making them highly malleable and adaptable for various shipbuilding requirements. This flexibility allows shipbuilders to create complex and streamlined designs, optimizing the vessel's performance and fuel efficiency. Furthermore, aluminum coils are environmentally friendly as they are 100% recyclable, reducing the carbon footprint associated with marine vessel production. This aspect aligns with the growing demand for sustainable and eco-friendly shipbuilding practices. In conclusion, aluminum coils play a vital role in the production of marine vessels. Their lightweight nature, corrosion resistance, thermal conductivity, malleability, and recyclability make them an ideal choice for shipbuilders. By utilizing aluminum coils, marine vessels can be constructed to be more efficient, durable, and environmentally friendly.

Send your message to us

Stucco Embossed Aluminum Coil for High Performance Refrigeration Aluminum Condenser Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords