Reflective Stucco Embossed Aluminum Coil for Transportation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Stucco Embossed Aluminum Coill for Transportation

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3A21 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum or paper |

7) Coil Inner diameter | 75mm, 150mm, 200mm, 300mm, 405mm, 505mm or as required |

8) Protective film can be added

2. Application of Stucco Embossed Aluminum Coill for Transportation

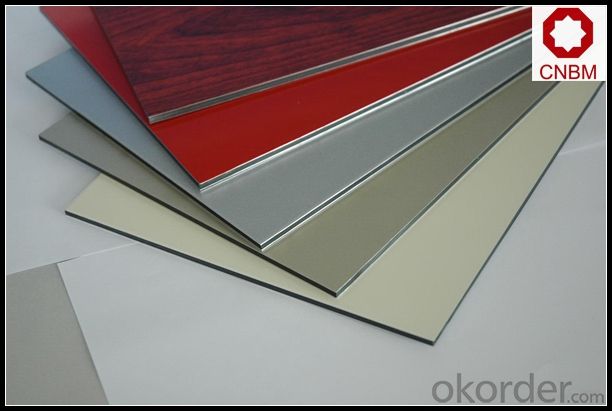

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Stucco Embossed Aluminum Coill for Transportation

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

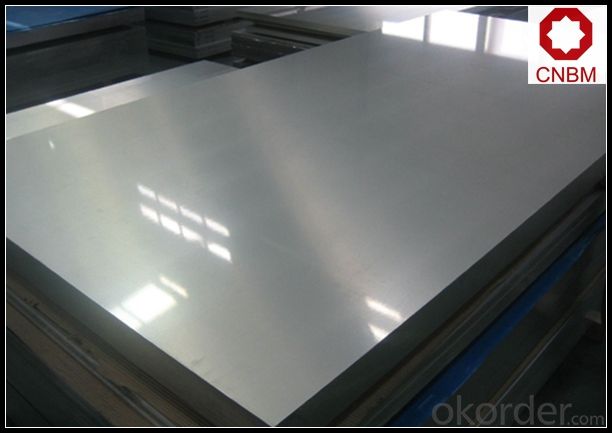

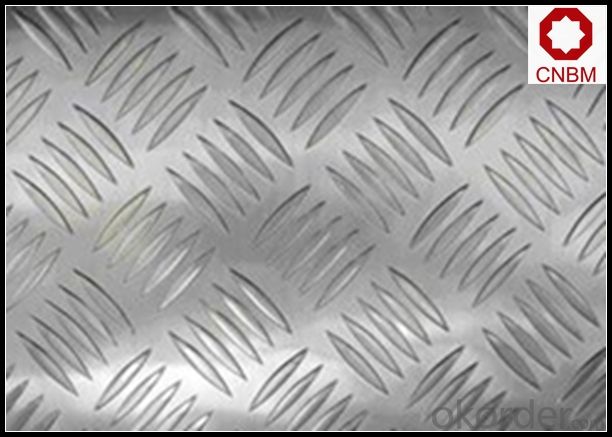

5. Image of Stucco Embossed Aluminum Coill for Transportation

6. Package and shipping of Stucco Embossed Aluminum Coill for Transportation

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: How are aluminum coils protected against bending and warping during storage?

- Aluminum coils are protected against bending and warping during storage through proper handling and packaging techniques. They are typically stored horizontally on specially designed racks or pallets to evenly distribute the weight and minimize stress on the coils. Additionally, they are often wrapped in protective materials such as stretch films or plastic sheets to provide an extra layer of cushioning and prevent any external forces from causing deformation.

- Q: aluminum welding

- Impossible. You need a TIG welder with AC and high frequency. Although you CAN use solid wire MIG with 100% argon shield gas, this is not a job for amateurs. MIG welding aluminum requires professional-grade equipment and several years experience with welding.

- Q: This question asks for methods to assess the quality of aluminum coils, which is important for various industries that use aluminum for manufacturing and construction.

- <p>To check the quality of aluminum coils, you should inspect for surface defects such as scratches, dents, or discoloration. Measure the thickness and width to ensure they meet specifications. Test the hardness and tensile strength to verify mechanical properties. Conduct a chemical analysis to confirm the alloy composition. Check for internal defects using non-destructive testing methods like ultrasonic testing. Assess the coil's flatness and straightness to prevent issues in further processing. Finally, ensure proper packaging and storage conditions to maintain coil quality.</p>

- Q: Can aluminum coils be used in building facades?

- Yes, aluminum coils can be used in building facades. Aluminum is a popular material choice for building facades due to its numerous benefits. It is lightweight, durable, and corrosion-resistant, making it suitable for exterior applications. Aluminum coils can be formed into various shapes and sizes, allowing for creative and versatile design possibilities. Additionally, aluminum is available in a wide range of finishes, including anodized, painted, and coated, providing further customization options for building facades. Moreover, aluminum is a sustainable material as it is 100% recyclable, making it an environmentally friendly choice for construction projects. Overall, aluminum coils are a viable option for building facades, providing both aesthetic appeal and functional performance.

- Q: What is the difference between hot rolled and cold rolled aluminum coils?

- The main difference between hot rolled and cold rolled aluminum coils lies in their production process and the resulting properties of the final product. Hot rolled aluminum coils are produced by heating aluminum ingots above their recrystallization temperature, typically around 450°C (842°F), and then rolling them through a series of rollers to reduce their thickness and shape them into coils. This process allows for quick production and the ability to produce larger coils. However, hot rolling can lead to a less precise and less smooth surface finish, with potential for surface defects and oxidation. On the other hand, cold rolled aluminum coils are produced by further processing hot rolled coils. The hot rolled coils are first pickled, or chemically treated, to remove any mill scale or impurities. They are then cold rolled, which involves passing them through a series of rollers at room temperature. This process results in a more precise and smoother surface finish, with excellent dimensional accuracy and tighter tolerances. Cold rolling also increases the strength and hardness of the aluminum, making it more suitable for certain applications. In terms of properties, hot rolled aluminum coils generally have lower strength and hardness compared to cold rolled coils. They also have a higher likelihood of surface defects and oxidation due to the high temperature involved in the production process. Cold rolled aluminum coils, on the other hand, exhibit higher strength and hardness, as well as better surface finish and dimensional accuracy. These properties make cold rolled aluminum coils more suitable for applications that require higher quality and precision. Overall, the choice between hot rolled and cold rolled aluminum coils depends on the specific requirements of the end-use application. Hot rolled coils are often used in applications where speed and cost-effectiveness are prioritized, while cold rolled coils are preferred for applications that demand higher quality, precision, and strength.

- Q: Are there any specific safety guidelines for installing aluminum coils?

- Yes, there are specific safety guidelines for installing aluminum coils. It is important to follow manufacturer instructions and guidelines, wear appropriate personal protective equipment (PPE), and ensure proper handling and storage of the coils. Additionally, one should be cautious of sharp edges and edges of the coils to prevent injuries during installation.

- Q: Is it possible to utilize an aluminum coil for heating purposes?

- <p>Yes, aluminum coil can be used as a heater. Aluminum is a good conductor of heat, making it suitable for applications where heat transfer is necessary. However, it's important to note that aluminum has a lower melting point compared to other metals like copper or steel, so it's not ideal for high-temperature applications. Aluminum coils are commonly used in electric heaters, such as toasters and air heaters, where they can efficiently transfer heat to the surrounding air or materials. Always ensure that the aluminum coil is used within safe temperature limits to prevent damage or safety hazards.</p>

- Q: Are there any limitations on the length of aluminum coils?

- The length of aluminum coils is indeed constrained by several practical factors. These factors include transportation, handling, and manufacturing capabilities. Transportation presents a significant limitation, as longer coils can be challenging to move efficiently. Loading, unloading, shipping, and logistics become more difficult due to the size and weight of these coils. Specialized equipment may be necessary, which can increase costs and complexity. Handling is another constraint, as longer coils are harder to maneuver and manipulate during production. Larger and more robust machinery may be required, which may not be available or feasible in all manufacturing facilities. Manufacturing capabilities also impose restrictions on coil length. Equipment used for coil production may have size and capacity limitations. Coil processing lines and machinery may have maximum lengths they can handle, and exceeding these limits may not be possible or economically viable. In conclusion, while there is no universal limit on aluminum coil length, practical constraints in transportation, handling, and manufacturing can impose limitations. The specific length of aluminum coils depends on factors such as transportation capabilities, handling feasibility, and manufacturing processes.

- Q: Can aluminum coils be used in the manufacturing of cans?

- Aluminum coils play a crucial role in the production of cans. They are commonly utilized to manufacture thin aluminum sheets, which are subsequently molded into cans. To achieve the desired thickness and width for can production, the coils undergo a series of steps, including rolling, annealing, and slitting. Once the aluminum sheets are prepared, they are cut into suitable sizes and shaped into the familiar cylindrical can form. Aluminum is a favored material for can manufacturing because of its lightweight, durable, and corrosion-resistant properties. Moreover, it serves as a protective barrier against light, oxygen, and moisture, thus ensuring the preservation of the contents' quality and shelf life. In summary, aluminum coils are an indispensable element in the can manufacturing process and play a significant role in the packaging industry.

- Q: Can aluminum coils be used in food storage facilities?

- Yes, aluminum coils can be used in food storage facilities. Aluminum is a widely used material in the food industry due to its excellent properties such as its lightweight, durability, corrosion resistance, and heat conductivity. These qualities make aluminum coils suitable for various applications in food storage facilities. Aluminum coils can be utilized in refrigeration systems, air conditioning units, and food storage cabinets, among others. Additionally, aluminum is non-toxic and does not react with food or alter its taste, making it a safe option for food storage. However, it is important to ensure that the aluminum coils used in food storage facilities are properly cleaned and maintained to prevent any potential contamination.

Send your message to us

Reflective Stucco Embossed Aluminum Coil for Transportation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords