ASTM B-209 Standards 3000 Series Stucco Embossed Aluminium Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of ASTM B-209 Standards 3000 Series Stucco Embossed Aluminium Coil

Thickness | 0.1mm-10mm |

Popular Thickness | 0.1mm/0.2mm/0.25mm/0.3mm/0.6mm/0.8mm/1.0mm/1.2mm/1.5mm/2.0mm/3.0mm... |

Width | 20mm-2500mm |

inner diameter | 505mm 508mm 605mm |

Material | 1050,1060,1070,1100,1200,3003,3004,3005,5052,5005,5754,5083 |

Temper | O,H12,H14,H16,H18,H22,H24,H26,H32,H34,H36,H38,H111,H112 |

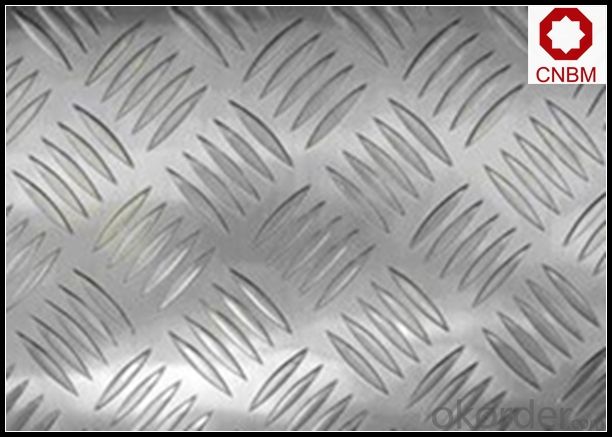

Surface | mill finish |

Packing | Export standard wooden pallets |

Payment Terms | 100% irrevocable L/C at sight or 30% T/T in advance as deposit,70% balance against the B/L copy |

Minimum Order Quantity | 5000kg |

Delivery time | 15-25 days after receiving L/C or deposit |

Remark | Specific requirement of alloy grade, temper or specification can be discussed at your request |

2. Application of ASTM B-209 Standards 3000 Series Stucco Embossed Aluminium Coil

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of ASTM B-209 Standards 3000 Series Stucco Embossed Aluminium Coil

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

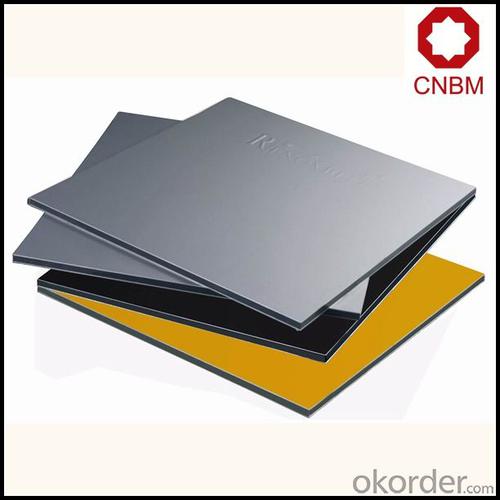

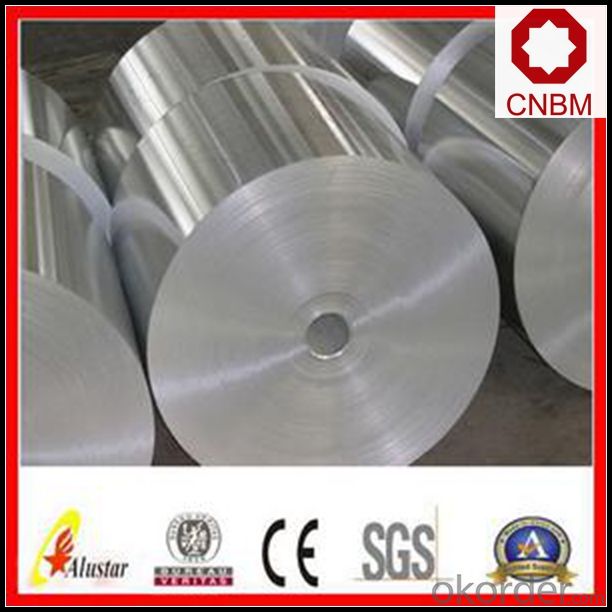

5. Image of ASTM B-209 Standards 3000 Series Stucco Embossed Aluminium Coil

6. Package and shipping of ASTM B-209 Standards 3000 Series Stucco Embossed Aluminium Coil

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What is the mass of 3.45 moles of Aluminum sulfate?Can u explain how?

- Aluminum sulfate is Al2S3, so you got two atoms of aluminum and three of oxygen. Hence the molar mass of aluminum sulfate is: 2X16 (two times molar mass of oxygen) + 3X32 (three times molar mass of sulfur). Keep in mind that the molar mass of an elements equals its mass number. We have 128 grams per mole or 128 pounds per lb-mol. Since you have 3.45 moles of Al2S3 you just have to do 3.45 times 128 = 441.6 grams

- Q: Can aluminum coils be used for gutter systems?

- Indeed, gutter systems can employ aluminum coils. The lightweight property, durability, and resistance to rust and corrosion make aluminum a favored material for gutters. It is common practice to utilize aluminum coils to shape seamless gutters, which present benefits such as reduced leakage and an enhanced visual appeal. Moreover, maintaining aluminum gutters is effortless, and they can be painted to harmonize with a building's exterior. All in all, aluminum coils are a fitting and frequently employed option for gutter systems.

- Q: How do aluminum coils contribute to recyclability in the construction industry?

- Aluminum coils play a crucial role in enhancing recyclability in the construction industry due to their inherent properties and characteristics. Firstly, aluminum is a highly recyclable material, meaning it can be recycled repeatedly without losing its quality or physical properties. This makes aluminum coils a sustainable and eco-friendly choice for construction projects. The recyclability of aluminum coils helps reduce the environmental impact associated with the construction industry. By choosing aluminum coils, construction companies can contribute to the conservation of natural resources and the reduction of energy consumption. Recycling aluminum requires significantly less energy than producing it from raw materials, resulting in a substantial reduction in greenhouse gas emissions and carbon footprint. Moreover, the use of aluminum coils in construction facilitates the dismantling and deconstruction processes, making it easier to separate the aluminum components from other materials. This efficient separation allows for the effective recycling of aluminum coils, ensuring that they can be transformed into new products or materials. Additionally, aluminum's durability and resistance to corrosion make it a suitable choice for construction applications. Its long lifespan reduces the need for frequent replacements, further minimizing waste generation and the consumption of raw materials. When the time comes to replace or renovate a building, the aluminum coils can be easily collected, recycled, and reintroduced into the manufacturing cycle, closing the loop of the material's lifecycle. In summary, aluminum coils significantly contribute to recyclability in the construction industry. Their high recyclability, low energy requirements for recycling, and ease of separation during deconstruction make them an environmentally friendly choice. By utilizing aluminum coils, the construction industry can promote sustainability, reduce waste generation, and conserve natural resources, ultimately leading to a greener and more circular construction sector.

- Q: Can you create a tank, AFV, IFV etc. from aluminium or is this just a stupid idea that would kill everyone inside?

- An aluminum tank hmmm? Great idea - for the enemy. Have you ever seen aluminum burn when it gets really hot Like if it is hit by a cannon shell or a grenade. Heavy enough high grade aluminum 6016 or so, could stop rifle shots but that's about hit.

- Q: What are the different coil leveling options available for aluminum coils?

- There are several coil leveling options available for aluminum coils, including tension leveling, temper leveling, and stretcher leveling. Tension leveling involves stretching the coil to remove any shape defects and improve flatness. Temper leveling involves subjecting the coil to controlled heating and cooling cycles to relieve internal stresses and improve flatness. Stretcher leveling involves stretching the coil beyond its yield point to permanently remove shape defects and improve flatness. These different options allow for customized leveling techniques based on the specific requirements of the aluminum coil.

- Q: This question asks for an explanation of the distinctions among various grades of hot rolled aluminum coils, focusing on their characteristics and applications.

- <p>Different grades of hot rolled aluminum coils are distinguished by their chemical composition, mechanical properties, and applications. Grades like 1000 series are pure aluminum with high ductility and electrical conductivity, suitable for general purposes. 3000 series, with added manganese, offer moderate strength and are used in cooking utensils and chemical equipment. 5000 series, containing magnesium, are strong and corrosion-resistant, used in marine applications and aerospace. 6000 series, with silicon and magnesium, are known for their mechanical strength and are used in construction and automotive parts. Each grade has specific alloying elements that tailor its properties for different industrial needs.</p>

- Q: This question asks for a comparison between aluminum coils and other metal coils, highlighting their distinct characteristics.

- <p>Aluminum coil is distinct from other metal coils due to its lightweight, high corrosion resistance, and excellent thermal and electrical conductivity. Compared to steel coils, aluminum coils are softer and more ductile, making them easier to bend and shape without breaking. They are also non-magnetic and have a lower melting point. Copper coils, on the other hand, have superior electrical conductivity but are heavier and more expensive. Zinc coils offer good corrosion resistance but are less ductile and have lower strength. Each metal coil has specific properties that make them suitable for different applications, such as construction, electrical wiring, or automotive parts.</p>

- Q: i am thnking of building my own aluminum john boat and using the propulsion from a jetski to power it, i was wondering if anyone had taken on a project like this and had a few pieces of advice to offer while i am still in the planning stages. the biggest concern i have right now involves the tunnel for the intake, should i use the original fiberglass from the jetski or build up a tunnel out of aluminum for it?

- I have built from both aluminum and steel. It sounds interesting and I would suggest using the fiberglass set up as all the clearances are set so you could just bond it to the aluminum. You can bond a fiberglass structure to aluminum by both bolting it up and bedding it down with something like 3M 5200.

- Q: Are aluminum coils resistant to moisture?

- Yes, aluminum coils are highly resistant to moisture. Aluminum has a natural oxide layer that forms on its surface, which acts as a protective barrier against moisture and prevents corrosion. This makes aluminum coils an excellent choice for applications where exposure to moisture is a concern, such as in HVAC systems or outdoor equipment.

- Q: What are the different finishes available for aluminum coils?

- There are several different finishes available for aluminum coils, each offering unique properties and aesthetics. 1. Mill Finish: This is the most basic and common finish for aluminum coils. It is the natural appearance of aluminum without any additional treatment or coating. Mill finish provides a smooth and shiny surface, but it is not as resistant to corrosion as other finishes. 2. Anodized Finish: Anodizing is an electrochemical process that enhances the corrosion resistance and durability of aluminum. This finish creates a thick, protective layer on the surface of the aluminum coil, making it highly resistant to weathering, scratches, and fading. Anodized finishes are available in a range of colors and can also be customized to match specific design requirements. 3. Painted Finish: Aluminum coils can be painted with various types of coatings to achieve specific colors, textures, and levels of durability. These coatings are typically applied using a coil coating process, where the paint is evenly distributed and cured onto the surface of the aluminum. Painted finishes offer excellent color retention, weather resistance, and can be tailored to meet specific project needs. 4. Brushed Finish: This finish is achieved by mechanically brushing the surface of the aluminum coil with abrasive materials, resulting in a textured appearance. Brushed finishes provide a unique aesthetic appeal and can hide scratches and blemishes. They are commonly used in architectural applications such as interior design, signage, and furniture. 5. Embossed Finish: Embossing involves imprinting a pattern or design onto the surface of the aluminum coil. This finish adds texture and visual interest to the material, making it suitable for decorative purposes. Embossed finishes can mimic various textures, such as wood grain or stucco, and are widely used in building facades, roofing, and signage. 6. Laminated Finish: Laminating involves bonding a layer of protective film or sheet onto the surface of the aluminum coil. This finish provides additional protection against scratches, stains, and UV rays. Laminated finishes are commonly used in applications that require high durability, such as transportation, appliances, and electronic enclosures. Overall, the choice of finish for aluminum coils depends on the specific requirements of the project, including aesthetics, durability, and environmental factors.

Send your message to us

ASTM B-209 Standards 3000 Series Stucco Embossed Aluminium Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords