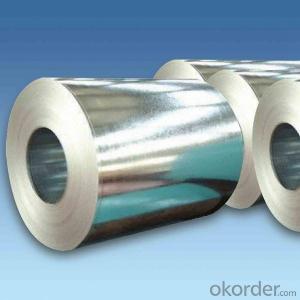

Hot Rolled Stainless Steel Coils 316 NO.1 Finish From China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Products Description for Stainless Steel Coils/Sheets:

Name: stainless steel coils/plates/sheets

Discharge Port: Any Port, China

Cold Rolled Size: Thickness0.3-8mm,Width:280-2100mm

Hot Rolled Size: Thickness3-14mm,Width:650-2100mm

Hot Rolled/Cold Rolled Plates : Thickness2-80mm,Width:1500-3000mm

Coil Weight: About 20 Tons

Grade: 201,202,304/304L/304H, 316/316L/316H, 409/L,430 etc.

Technique: Hot Rolled/Cold Rolled

Finish:2B, BA, 2D, No1, No2 etc

Edge: Mill Edge / Slitting Edge

Packaging: In bundles, or as customer's requirement

Place of Origin: Made in China

MOQ: 20 Tons

Payment Terms: 100% LC at sight, or 100%TT in advance

Delivery Time: With 30-40 days after deposit

Application for Stainless Steel Coils/Sheets:

Boiler heat exchanger, machinery andpetroleum ,chemical industries, hardware fields,Food industry,construction material,kitchen utensils, building construction, medical equipment,chemical tank, pipe etc

Detail picture for Stainless Steel Coils/Sheets

Packaging & Delivery for Stainless Steel Coils/Sheets:

Packaging Detail | Standard export packing or following customer's demand |

Delivery Time | Within 30-40 days after deposit or according to the order quantity |

FAQ for Stainless Steel Coils/Sheets:

Q:What are the advantages of your company ?

A: We have many professionals, technical personnel, more competitive prices and best after-dales service than other stainless steel companies.

Q:Can you arrange the shipment ?

A: Sure we can help you with the shipment. We have forwarders who have cooperated with us for many years.

- Q: How do you clean stainless steel sheets?

- To clean stainless steel sheets, you can start by wiping them down with a soft cloth or sponge dipped in mild soapy water. Avoid using abrasive cleaners or scrub brushes as they can scratch the surface. Rinse the sheets thoroughly with clean water and dry them with a soft towel to prevent water spots. For stubborn stains or fingerprints, you can use a stainless steel cleaner or a mixture of vinegar and water. Gently scrub the affected areas with a soft cloth, rinse, and dry.

- Q: Can stainless steel sheets be used for elevator doors or panels?

- Yes, stainless steel sheets can be used for elevator doors or panels. Stainless steel is a common material used in elevator construction due to its durability, strength, and aesthetic appeal. It is resistant to corrosion, which is essential for elevator doors and panels that are exposed to various environmental conditions. Stainless steel sheets can be easily formed and fabricated to meet the specific design requirements of elevator doors and panels. Additionally, stainless steel is easy to clean and maintain, making it a popular choice for high-traffic areas like elevators.

- Q: What is the elongation of stainless steel sheets?

- The elongation of stainless steel sheets refers to the ability of the material to stretch or deform under tension before breaking. It is typically expressed as a percentage and represents the maximum strain the steel can undergo without fracturing.

- Q: Can stainless steel sheets be used for elevator flooring?

- Stainless steel sheets are indeed suitable for elevator flooring. The reason behind their popularity lies in their exceptional durability, strength, and corrosion resistance. These sheets can effortlessly withstand substantial foot traffic while ensuring effortless cleaning and maintenance. Moreover, stainless steel possesses an aesthetic charm that lends elevators a sleek and contemporary appearance.

- Q: Can stainless steel sheets be used in decorative applications?

- Certainly, decorative applications can certainly make use of stainless steel sheets. Stainless steel possesses great versatility, allowing it to be shaped, patterned, and finished in a variety of ways, rendering it an exceptional option for decorative purposes. Its sleek and contemporary look adds a dash of sophistication to any area, and it can be utilized in a multitude of ways, such as wall cladding, backsplashes, cabinet fronts, countertops, and furniture embellishments. Moreover, stainless steel sheets exhibit remarkable durability, resistance to corrosion, and ease of maintenance, making them an ideal choice for both indoor and outdoor decorative applications.

- Q: What does "stainless steel plate" 6.0*1500c mean?

- Stainless steel plate 6.0*1500c represents stainless steel material,6 represents the stainless steel thickness,

- Q: How are stainless steel sheets finished?

- Stainless steel sheets can be finished in various ways to achieve different appearances and textures. The most common finishing techniques for stainless steel sheets include: 1. Mill Finish: This is the standard finish when stainless steel sheets are initially produced. It has a dull, non-reflective surface with visible grain lines caused by the manufacturing process. 2. Brushed Finish: Also known as satin finish, this technique involves brushing the stainless steel surface with an abrasive material to create a consistent, fine grain appearance. It provides a smooth and matte finish, which is often preferred for aesthetic purposes. 3. Mirror Finish: As the name suggests, this finish creates a highly reflective and mirror-like surface on stainless steel sheets. It is achieved by polishing the surface with progressively finer grits of abrasive materials until a smooth and reflective finish is obtained. 4. Embossed Finish: This finish involves impressing a pattern or design onto the stainless steel sheet surface. Embossing can be done using heat and pressure to create raised or recessed patterns, adding texture and visual interest to the sheet. 5. Bead Blasted Finish: This technique uses fine glass beads or other abrasive materials to blast the stainless steel surface. It creates a uniform, matte appearance with a slightly textured finish. 6. PVD Coating: Physical Vapor Deposition (PVD) is a process where a thin layer of metal or alloy is vaporized and deposited onto the stainless steel sheet surface. This coating enhances the appearance of the sheet, providing various colors and finishes such as gold, bronze, or black. Overall, choosing the appropriate finish for stainless steel sheets depends on the desired aesthetic, functionality, and application of the material. Each finish has its unique characteristics, allowing for versatility and customization in different industries, including architecture, interior design, automotive, and many others.

- Q: Are stainless steel sheets environmentally friendly?

- Yes, stainless steel sheets are considered environmentally friendly. Stainless steel is a highly sustainable material that can be recycled indefinitely without losing its properties. It is non-toxic, durable, and resistant to corrosion, reducing the need for replacements and minimizing waste. Additionally, the production process of stainless steel sheets has a lower environmental impact compared to other materials, making it an eco-friendly choice.

- Q: What is stainless steel AB board, please?

- The 2B board is basically a matt surface, according to a BA object, in approximate mirror, can more clearly illuminate the object (a little paste).

- Q: Are stainless steel sheets suitable for outdoor sculptures or artwork?

- Yes, stainless steel sheets are highly suitable for outdoor sculptures or artwork. Stainless steel is known for its exceptional durability, corrosion resistance, and weather resistance, making it a perfect choice for outdoor installations. It can withstand harsh environmental conditions such as rain, snow, UV rays, and temperature fluctuations without losing its structural integrity or aesthetic appeal. Moreover, stainless steel can be easily shaped, cut, and welded, offering great flexibility for artists and designers to create intricate and complex sculptures. Additionally, stainless steel has a sleek and modern appearance, which can add a contemporary touch to any outdoor setting. Its low maintenance requirements and ability to retain its original finish for an extended period make it a cost-effective choice for outdoor sculptures or artwork. Therefore, stainless steel sheets are an excellent material option for creating long-lasting and visually appealing outdoor artworks.

Send your message to us

Hot Rolled Stainless Steel Coils 316 NO.1 Finish From China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords