20mnsi Q235 Square Bar Steel Billets 3SP 5SP 20MnSi for Ceramic Tunnel Kiln

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

20mnsi Q235 Square Bar Steel Billets 3SP 5SP 20MnSi for Ceramic Tunnel Kiln

Description

Reference Price:$260/ton Mn 0.3%-0.6%

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Billet: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod. ,

Steel billets have distinct characteristics as compared with already furnished steel bars and products. Billets have a specific grain structure, which enables the metal to be processed more intricately. Steel billets are also known for their malleability and ductility, especially when exposed to varying temperatures during shaping and molding.

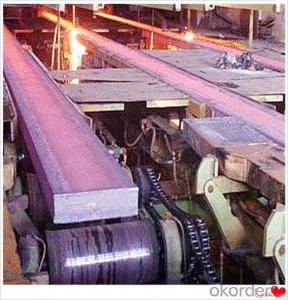

Processing of Steel Billet

Steel billets are considered fresh and raw, and they must undergo a series of manufacturing processes before they can be used for various purposes. Billets are made by means of freezing molten liquid, and are later exposed to extremely low temperatures in order to allow the metal to take shape and solidify in chemical structure. The temperature manipulates the metal's physical properties, and tones its strength and durability. The subsequent processes provide the metal's curved mold design so that it can fit the allotted space provided by other machines, which complete the finishing procedures.

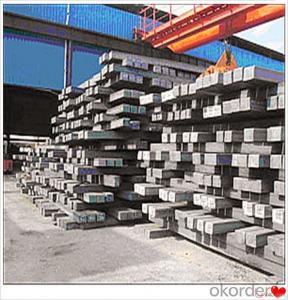

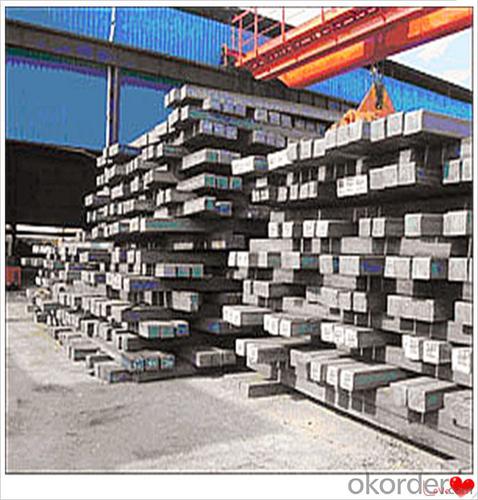

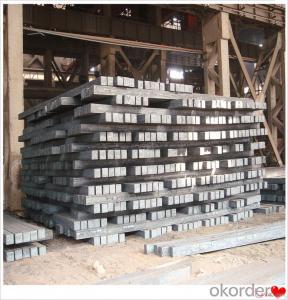

Images

Technical Data

Size:100*100,120*120,150*150,130*130

Mn: 0.3%-0.6%

C: 1%

Cr:0.1%

Packaging

cargo ship or container

usually container price will add 15USD per ton

RFQ

We have organized several common questions for our clients,may help you sincerely:

1) How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3) How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

4)Do you have your own QC department?

Yes, we have, our QC department will inspect the goods during the process of mass production and after completion of production.

hot sale!!! steel billets/ mild steel bar/ billet steel

(1): High quality steel with reasonable price.

(2): Wide excellent experiences with after-sale service.

(3): Every process will be checked by responsible QC which insures every product's quality.

(4): Professional packing teams which keep every packing safely.

(5): Trial order can be done in one week.

(6): Samples can be provided as your requirements.

If you are interested in our products, please don't hesitate to contact me.

Your any inquiry will be appreciated and we will offer you a rock-bottom price.

- Q: Are steel billets used in the production of electrical appliances?

- Steel billets are widely utilized in the production of electrical appliances. This versatile material possesses numerous benefits, including strength, durability, and corrosion resistance. Hence, it finds extensive application in manufacturing different components of electrical appliances, such as outer casings, frames, and internal structural supports. Steel billets serve as an intermediary product during the steel manufacturing process and can be further transformed into various shapes and sizes to cater to the specific demands of electrical appliance production.

- Q: What are the main factors that determine the pricing strategy of steel billets manufacturers?

- The pricing decisions made by manufacturers in the steel billets industry are influenced by several crucial factors, which play a significant role in shaping their pricing strategy. Firstly, the cost of raw materials, particularly iron ore and scrap metal, is a key determinant in the pricing strategy. Fluctuations in these material costs can directly impact overall production costs and subsequently affect the pricing of steel billets. Secondly, the production capacity of a steel billets manufacturer is a factor that influences their pricing strategy. Manufacturers with higher production capacity may be able to achieve economies of scale, resulting in lower production costs and potentially more competitive pricing. Moreover, market demand for steel billets is an essential factor in pricing decisions. Higher demand often allows manufacturers to set higher prices, while lower demand may require more competitive pricing strategies to attract customers. Additionally, the level of competition within the steel billets industry is significant in determining pricing strategies. Manufacturers must consider the pricing strategies of their competitors to ensure that they remain competitive in the market. Factors such as market share, product differentiation, and branding can influence a manufacturer's ability to set prices. Transportation and logistics costs also impact pricing decisions. Manufacturers that are closer to raw material sources or major markets may have a cost advantage over those located further away. Transportation costs, including fuel prices, shipping fees, and infrastructure quality, can influence the final pricing strategy. Government regulations, such as import/export duties, taxes, and tariffs, have an impact on the pricing strategy of steel billets manufacturers. These regulations can affect the cost of raw materials or the ability to access certain markets, ultimately influencing pricing decisions. Furthermore, economic factors such as inflation rates, interest rates, and exchange rates can impact the pricing strategy. Manufacturers need to consider these factors to ensure that their prices remain competitive and reflect changes in the overall economic climate. In conclusion, the pricing strategy of steel billets manufacturers is a complex interplay of various factors, including raw material costs, production capacity, market demand, competition, transportation costs, government regulations, and economic factors. Manufacturers must carefully analyze these factors to determine a pricing strategy that maximizes profitability while remaining competitive in the market.

- Q: Can steel billets be used in the production of agricultural equipment?

- Steel billets have the potential to be utilized in the manufacturing process of agricultural equipment. These billets are essentially unfinished products that are typically formed through a continuous casting method. They can undergo further processing to take on various shapes and sizes, which makes them suitable for the production of agricultural machinery like plows, cultivators, harrows, seeders, and other similar farm equipment. The utilization of steel billets in agricultural machinery brings about numerous benefits. Steel is renowned for its robustness, longevity, and resistance to deterioration, making it ideal for heavy-duty applications within the agricultural sector. Moreover, steel is capable of withstanding harsh environmental conditions, ensuring that the machinery remains dependable and functional even in demanding farming environments. Furthermore, steel can be easily shaped and fabricated into different forms, allowing for the customization of agricultural equipment to meet specific requirements. Overall, incorporating steel billets in the manufacturing process of agricultural equipment enhances the efficiency, productivity, and longevity of farming operations.

- Q: What are the potential applications of steel billets in the agricultural sector?

- The agricultural sector can benefit greatly from the various potential applications of steel billets. One primary use of steel billets in agriculture involves their utilization in the manufacturing of farm equipment and machinery. Plows, cultivators, and seeders, which are essential for tilling the soil, planting seeds, and maintaining agricultural land, can be produced using steel billets to create durable and sturdy components. Steel billets also find usefulness in the construction of storage structures on farms. Due to its strength and durability, steel is an ideal material for constructing grain silos, barns, and sheds. These structures provide long-lasting and reliable solutions for storing crops, livestock, and equipment. Furthermore, steel billets can be used to fabricate fences and gates for animal enclosures. Steel fences offer superior strength and security, ensuring the safety of farm animals and preventing them from wandering off. These fences are also resistant to corrosion and capable of enduring harsh weather conditions. Moreover, steel billets can be employed in the construction of irrigation systems and water management infrastructure on farms. Steel pipes and fittings are commonly used to transport water from a source to the fields, promoting proper irrigation and efficient water distribution. Lastly, steel billets can be employed in the production of machinery used for processing agricultural products. Grain mills, threshers, and sorting machines, for example, can be manufactured with steel components, aiding in the processing and packaging of crops. Overall, the potential applications of steel billets in the agricultural sector are extensive and diverse. From farm equipment and storage structures to fencing and irrigation systems, steel billets play a vital role in enhancing efficiency, durability, and productivity in agriculture.

- Q: Are steel billets subject to any international standards?

- Yes, steel billets are subject to international standards. The International Organization for Standardization (ISO) has established several standards that govern the production, quality, and dimensions of steel billets. These standards ensure that steel billets meet specific criteria and are suitable for use in various industries, including construction, manufacturing, and engineering. ISO standards, such as ISO 683-2 and ISO 16143-1, provide guidelines for the chemical composition, mechanical properties, and tolerances of steel billets. Additionally, international trade organizations, such as the International Trade Commission (ITC) and the World Trade Organization (WTO), may also establish regulations and standards for the import and export of steel billets to ensure fair trade practices and product safety. Therefore, steel billets are subject to international standards to ensure consistency, quality, and compliance across different countries and markets.

- Q: Can steel billets be polished for improved surface finish?

- No, steel billets cannot be polished for improved surface finish as they are usually unfinished or have a rough surface due to the manufacturing process.

- Q: How are steel billets used in the manufacturing of industrial tools?

- Steel billets are used in the manufacturing of industrial tools as they serve as the initial raw material for various tool components. These billets undergo a series of processes such as heating, forging, and machining to shape them into the desired tool parts, such as blades, bits, or molds. The superior strength and durability of steel make it an ideal material for industrial tools, ensuring their ability to withstand heavy usage and challenging working conditions.

- Q: How are steel billets used in the production of turbine blades?

- Steel billets are an integral component in the production of turbine blades. These billets, which are essentially semi-finished steel products, serve as the starting material for the manufacturing process. To begin with, steel billets are carefully selected based on specific requirements such as composition, strength, and durability. Once chosen, they undergo a series of processing steps to shape them into turbine blades. The first step involves heating the steel billets to high temperatures in a furnace. This process, known as forging, makes the steel more malleable and easier to work with. Once heated, the billets are then subjected to mechanical forces that shape them into the desired form of turbine blades. After the initial forging process, the turbine blades are further refined through various machining operations. This includes precision cutting, grinding, and drilling to achieve the required dimensions, surface finish, and aerodynamic profiles. In addition to shaping and refining, steel billets also play a crucial role in enhancing the strength and integrity of turbine blades. Through heat treatment processes such as quenching and tempering, the billets are hardened and tempered to achieve the desired mechanical properties, such as high strength and resistance to fatigue. Furthermore, steel billets provide the necessary material properties to withstand the harsh operating conditions of turbines. They offer excellent corrosion resistance, which is essential for blades operating in environments exposed to high temperatures, pressure, and moisture. Overall, steel billets are essential in the production of turbine blades as they provide the starting material, allow for shaping and refinement, and offer the necessary strength and durability required for these critical components in power generation.

- Q: How do steel billets contribute to the manufacturing of telecommunications equipment?

- The manufacturing of telecommunications equipment heavily relies on steel billets as they supply the essential raw material for various components and structures. These billets, typically composed of carbon steel, act as semi-finished products that undergo further processing to achieve specific shapes and sizes required for telecommunications equipment. A significant contribution of steel billets to the manufacturing of telecommunications equipment is their role as the base material for constructing towers and masts. These structures are crucial for antenna and satellite dish installation, facilitating the transmission and reception of signals within telecommunications networks. Steel billets are shaped and welded to create robust and long-lasting towers capable of withstanding diverse environmental conditions. Furthermore, steel billets find application in the production of enclosures and cabinets housing telecommunication equipment. These enclosures safeguard the equipment against external factors like dust, moisture, and vandalism, ensuring optimal functioning and longevity. Steel billets are transformed into panels, frames, and chassis, which are then assembled to form resilient enclosures capable of enduring harsh environments. Moreover, steel billets contribute to the manufacturing of telecommunications equipment by being employed in the production of cable trays and supports. These components are essential for organizing and routing cables, providing an efficient infrastructure for telecommunications systems. Steel billets are rolled and shaped into various forms, such as channels and angles, to produce sturdy cable trays and supports capable of withstanding the weight and stress of multiple cables. Additionally, steel billets are utilized in the fabrication of connectors and brackets for telecommunications equipment. These small yet vital components establish necessary connections and provide support for different devices and modules within telecommunications systems. Steel billets are subjected to machining, drilling, and shaping processes to create reliable connectors and brackets, ensuring proper functionality and stability. In conclusion, steel billets have an indispensable role in the manufacturing of telecommunications equipment due to their provision of essential raw material for various components and structures. Their strength, durability, and versatility make them an ideal choice for creating robust and reliable equipment capable of meeting the demands of modern communication networks.

- Q: What are the different surface defects that can occur in steel billets?

- Steel billets can suffer from a variety of surface defects. Among the most common are: 1. Scale: During heating, a rough, flaky oxide layer known as scale can form on the billet's surface. This coating can negatively impact the final product's quality. 2. Cracks: Thermal stress, improper handling, or excessive cooling can cause cracks to appear on the billet's surface. These cracks can be either longitudinal or transverse and compromise the overall structural integrity of the billet. 3. Decarburization: High temperatures or chemical reactions can lead to the reduction of carbon content at the steel's surface, a process known as decarburization. This weakens the outer layer, affecting the billet's mechanical properties. 4. Pits: Corrosion, inadequate cleaning, or chemical reactions can result in small depressions or cavities on the billet's surface, known as pits. Pits can reduce strength and create localized stress concentrations. 5. Surface roughness: Improper handling, insufficient machining, or poor surface finishing can leave steel billets with uneven or rough surfaces. This can impact the final product's appearance and performance. 6. Inclusions: Non-metallic materials become trapped in the steel during manufacturing, forming inclusions. They can appear as dark spots, streaks, or irregular shapes on the billet's surface. Inclusions weaken the steel and decrease its ductility. 7. Surface contamination: Handling or storage can introduce foreign materials like dirt, oil, or grease to steel billets, leading to surface defects, corrosion, or compromised quality. Detecting and addressing these surface defects early in the manufacturing process is crucial to ensure high-quality steel billets. Various inspection techniques, including visual examination, ultrasonic testing, and magnetic particle inspection, can be used to identify and mitigate these defects.

Send your message to us

20mnsi Q235 Square Bar Steel Billets 3SP 5SP 20MnSi for Ceramic Tunnel Kiln

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords