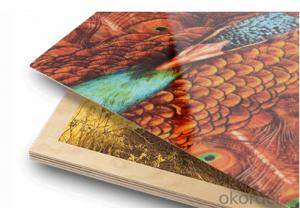

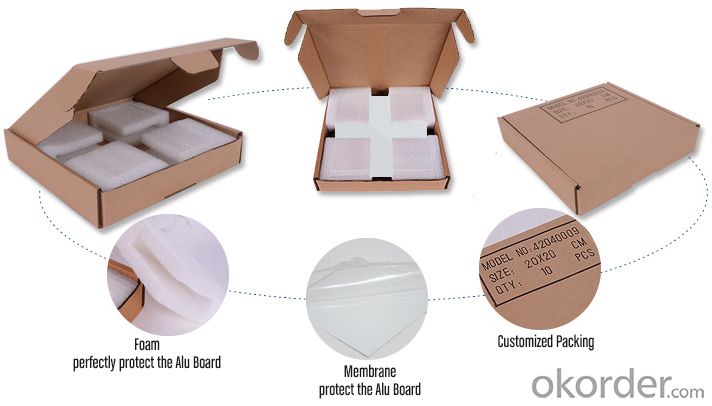

Painted Anodized Aluminum Sheets - Supplier Aluminium Metal Art Pictures Print on HD Aluminium Metal Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 carton

- Supply Capability:

- 20000 carton/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description:

These Aluminum Panels can provide for many sizes and different color. It can suitable in many occasion, like company logo screen, show backdrop, home use, some gift use etc. We can also provide the heat press machine for transferring.

Features:

1. Extremely durable scratch resistant surface that is waterproof and can be cleaned easily with a damp cloth.

2. Eco-friendly & Terrific as a decoration.

3. Longest lasting photo medium in the current market.

4. The high definition, vibrant colors coupled with superior fade, moisture, stain & scratch resistant properties.

5. The image is infused into the coating to provide permanent protection and durability.

6. Excellent choice for commercial, fine art, and home decoration applications.

Making Process:

1. Get images from digital camera, memory card or scanner.

2. Print image with heat transfer paper and sublimation ink.

3. Lay down a teflon sheet and your panel, and another CLEAN teflon sheet on top, pre-press for 60 sec., 180℃, 0.3Mpa.

4. 60 seconds later. Wait the panel to cool.

5. Tape the transfer to the face of the substrate with heat resistent tape running parallel to the edge of the substrate.

6. Lay substrate face up, transfer on top on a piece of telfon sheet on lower platen.

7. Cover with one layer of fabric, preferably 100% polyester or poly-silk, to distribute pressure and reduce stress on the coating.

8. Press for the prescribed time is 130sec., temperature is 180℃ and pressure is 0.3Mpa.

9. When finished, remove the fabric and gently peel the taped transfer off the substrate without allowing it to slide or move.

10. Let the substrate to cool. Do not handle it until cool to reduce the chances of damaging the coating on the edges.

11. Enjoy your personal designed aluminum board!

Free sample is OK

- Q: What is the maximum temperature that aluminum sheets can withstand?

- The maximum temperature that aluminum sheets can withstand depends on several factors such as the alloy composition, thickness, and intended application. Generally, aluminum has a melting point of around 660 degrees Celsius (1220 degrees Fahrenheit). However, aluminum sheets can typically withstand much higher temperatures without melting or deforming. For most commercially available aluminum alloys, the maximum temperature for continuous use ranges from 200-300 degrees Celsius (390-570 degrees Fahrenheit). Beyond this range, the material may start to experience reduced strength and increased susceptibility to deformation or damage. However, it is important to note that the specific maximum temperature limit for a particular aluminum sheet should be determined by consulting the manufacturer's specifications or conducting specific testing. Factors such as the presence of coatings or surface treatments, exposure to heat for extended periods, and thermal cycling can also affect the maximum temperature tolerance of aluminum sheets.

- Q: im making a presentation and once i read through it it feels like its leading up to something but then goes flat. any ideas. my project ' steel cars compared to aluminium'

- Aluminium is extremely flammable. We use it in thermite welding and as solid rocket fuel. The Emperor Napoleon carried* an aluminium fork while the lower royalty had to make do with gold forks. *In those days people carried their table wear around with them same as we carry our car keys.

- Q: When Aluminium nitrate is heated , i got yellow amorphous solid which did not not melt on further heating. What compound is that?

- Aluminium nitrate follows the rules for metal nitrate decomposition. Group I nitrate Na K etc --- nitrite + oxygen Other metal nitrate --- Metal Oxide + nitrogen dioxide + oxygen So your final product is aluminium oxide.

- Q: Can aluminum sheets be used for chemical pumps?

- No, aluminum sheets are not suitable for chemical pumps as they are not resistant to corrosion from many chemicals.

- Q: What are the different types of alloys used for aluminum sheets?

- There are several types of alloys commonly used for aluminum sheets, each with its own unique properties and applications. Some of the most common types include: 1. 1100 alloy: This alloy is pure aluminum with excellent corrosion resistance and good formability. It is often used for general sheet metal work, such as roofing and siding. 2. 3003 alloy: This alloy is similar to 1100 but with added manganese, making it slightly stronger. It is commonly used for applications that require moderate strength and good corrosion resistance, such as packaging and automotive parts. 3. 5052 alloy: This alloy is known for its excellent corrosion resistance, especially in marine environments. It also has good formability and weldability, making it suitable for various applications like fuel tanks, marine components, and architectural panels. 4. 6061 alloy: This alloy is one of the most versatile and widely used aluminum alloys. It offers excellent strength, weldability, and corrosion resistance. 6061 is commonly used in structural applications, such as aircraft parts, bicycle frames, and automotive components. 5. 7075 alloy: This high-strength alloy is often used in aerospace and military applications. It has excellent fatigue resistance and good machinability. 7075 is typically used for aircraft structures, missile parts, and high-stress components. These are just a few examples of the various types of aluminum alloys used for sheets. The specific alloy chosen will depend on the desired properties, such as strength, corrosion resistance, formability, and cost, as well as the intended application.

- Q: What are the different methods of surface preparation for aluminum sheets?

- There are several methods of surface preparation that can be used for aluminum sheets. These methods are designed to clean, treat, and prepare the surface of the aluminum to ensure optimal adhesion and paint durability. Here are some of the different methods of surface preparation for aluminum sheets: 1. Mechanical Abrasion: This method involves using abrasive materials such as sandpaper, wire brushes, or sandblasting to physically remove any dirt, rust, or oxidation from the surface of the aluminum. Mechanical abrasion creates a rough texture on the surface, which promotes paint adhesion. 2. Chemical Cleaning: Chemical cleaning involves using acidic or alkaline solutions to remove any contaminants or oxidation from the surface of the aluminum. This method is particularly effective for removing tough stains, oils, or greases. The surface is typically rinsed thoroughly after chemical cleaning to remove any residue. 3. Etching: Etching is a process that involves applying an acidic or alkaline solution to the aluminum surface to create a microscopically rough texture. This rough surface enhances paint adhesion and provides a better bonding surface for coatings. Etching is commonly used as a pre-treatment before applying a primer or paint. 4. Conversion Coating: Conversion coating is a surface treatment method that involves applying a chemical solution to the aluminum surface to create a thin, protective layer. This layer not only improves paint adhesion but also provides corrosion resistance. Common conversion coatings for aluminum include chromate conversion coatings and phosphoric acid anodizing. 5. Mechanical Cleaning: Mechanical cleaning involves using mechanical methods such as brushing, scraping, or buffing to remove loose particles, dirt, or debris from the surface of the aluminum. This method is often used as a preliminary step before applying other surface treatments or coatings. It is important to note that the choice of surface preparation method may vary depending on the specific requirements of the aluminum sheet's application, the condition of the surface, and the desired finish. Proper surface preparation is crucial to ensure the longevity and performance of the paint or coating applied to aluminum sheets.

- Q: This question asks about the structural integrity and suitability of aluminum sheets for use in the construction of high-rise buildings.

- <p>Aluminum sheets are not typically used as the primary structural material in high-rise buildings due to their lower strength compared to steel and concrete. However, aluminum is known for its high strength-to-weight ratio, making it suitable for non-structural applications such as facades, window frames, and roofing. In high-rise construction, aluminum can be used in combination with other materials to provide a lightweight and aesthetically pleasing exterior while maintaining structural integrity with stronger materials like steel and concrete.</p>

- Q: I need to make an aluminum cylinder out of 1/8 6061 plate and tube. I don't have a TIG setup and was considering using Bernzomatic aluminum soldering rods. The cylinder will be pressurized from 20-60 psi. Assuming a clean job, is this pressure ok? How much pressure can the joint take? Also, although the solder does not need flux, should i use it anyway?

- Whether that weld will be OK depends on the diameter of the cylinder. The force on the weld will be equal to the operating pressure time the radius of the cylinder, with the wall opposite the weld have an equal force. Divide that force by the thickness of the weld to figure the stress. You want to have a safety factor of about 3. As the Bernzomatic has either a brass or aluminum head, which would melt at the temperatures which are required for true welding (melting metals so that they flow together), you will be performing brazing with a Bernzomatic. I cannot comment on the strength of the brazing bond. The thickness of the brazing metal deposit depends on the strength of the brazing alloy, which I also cannot comment on. 6061 will melt at 1206°, which you will not approach with the Bernzo kit. A blowout of a metal cylinder at 60 psi could be pretty ugly. I suggest that you befriend someone who has a TIG welder and get their help. A properly welded 1/8 thick cylinder could handle about 660 psi with no problem. If you create a lap joint, using an outer strip of aluminum, and then band your cylinder with stainless steel hose clamps, you will be relying upon the brazing only to provide a gas seal. The strength would come from the hose clamps. You still need to do some calculation on forces involved. A 1/2 wide stainless hose clamp will probably hold back about 240 lb. of force with a comfortable margin of safety.

- Q: does aluminum sheet need to conduct ROHS detection?it's metel material, how much detections should it conduct for ROHS detection?

- It's ok for detecting four items of ROHS heavy metal for ROHS detection of metal material.

- Q: Can aluminum sheets be used for reflective insulation?

- Yes, aluminum sheets can be used for reflective insulation. Aluminum is highly reflective and has good thermal conductivity, making it an excellent choice for reflecting heat and reducing heat transfer. When used as insulation, aluminum sheets can reflect heat away from the surface, preventing it from entering or escaping the desired area. This can help in maintaining a comfortable temperature inside a building or protecting sensitive equipment from extreme heat or cold. Additionally, aluminum sheets are lightweight and easy to install, making them a popular choice for reflective insulation applications.

Send your message to us

Painted Anodized Aluminum Sheets - Supplier Aluminium Metal Art Pictures Print on HD Aluminium Metal Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 carton

- Supply Capability:

- 20000 carton/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords