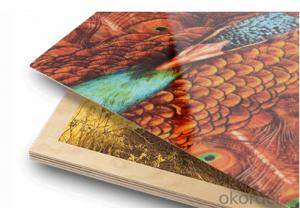

Wholesale Colored Aluminum Sheets - HD Aluminium Metal Art Pictures Print on HD Aluminium Metal Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 carton

- Supply Capability:

- 20000 carton/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description:

These Aluminum Panels can provide for many sizes and different color. It can suitable in many occasion, like company logo screen, show backdrop, home use, some gift use etc. We can also provide the heat press machine for transferring.

Features:

1. Extremely durable scratch resistant surface that is waterproof and can be cleaned easily with a damp cloth.

2. Eco-friendly & Terrific as a decoration.

3. Longest lasting photo medium in the current market.

4. The high definition, vibrant colors coupled with superior fade, moisture, stain & scratch resistant properties.

5. The image is infused into the coating to provide permanent protection and durability.

6. Excellent choice for commercial, fine art, and home decoration applications.

Making Process:

1. Get images from digital camera, memory card or scanner.

2. Print image with heat transfer paper and sublimation ink.

3. Lay down a teflon sheet and your panel, and another CLEAN teflon sheet on top, pre-press for 60 sec., 180℃, 0.3Mpa.

4. 60 seconds later. Wait the panel to cool.

5. Tape the transfer to the face of the substrate with heat resistent tape running parallel to the edge of the substrate.

6. Lay substrate face up, transfer on top on a piece of telfon sheet on lower platen.

7. Cover with one layer of fabric, preferably 100% polyester or poly-silk, to distribute pressure and reduce stress on the coating.

8. Press for the prescribed time is 130sec., temperature is 180℃ and pressure is 0.3Mpa.

9. When finished, remove the fabric and gently peel the taped transfer off the substrate without allowing it to slide or move.

10. Let the substrate to cool. Do not handle it until cool to reduce the chances of damaging the coating on the edges.

11. Enjoy your personal designed aluminum board!

- Q: How can I make aluminum oxide?

- Visit this link: okorder ... Hope it's useful to you!

- Q: Are aluminum sheets suitable for automotive applications?

- Yes, aluminum sheets are suitable for automotive applications. Aluminum is a lightweight material that offers several advantages for automotive use. Firstly, aluminum is highly corrosion resistant, making it ideal for exterior parts that are exposed to harsh environments. Additionally, aluminum offers great strength-to-weight ratio, meaning it provides high strength while keeping the overall weight of the vehicle low. This leads to improved fuel efficiency and better performance. Aluminum sheets are also easily formable, allowing manufacturers to create complex shapes and designs for various automotive components. Furthermore, aluminum is recyclable, making it an environmentally friendly choice. Overall, the use of aluminum sheets in automotive applications offers numerous benefits, including weight reduction, improved fuel efficiency, corrosion resistance, and design flexibility.

- Q: Can aluminum sheet be used for insulation?

- Aluminum sheet can be used for insulation, but it is not as effective as other insulation materials, such as fiberglass or foam. Aluminum has a low thermal conductivity, meaning it is a poor conductor of heat. However, it does not have good insulating properties on its own because it does not provide much resistance to heat flow. In order to use aluminum sheet for insulation, it is commonly combined with other insulating materials to enhance its effectiveness. For example, aluminum foil is often used as a radiant barrier in buildings to reflect heat and reduce the amount of heat transferred through walls and roofs. Overall, while aluminum sheet can contribute to insulation, it is usually used in conjunction with other materials to provide better thermal insulation.

- Q: Can the aluminum sheets be used for manufacturing chemical piping systems?

- Indeed, the utilization of aluminum sheets in the production of chemical piping systems is plausible. Renowned for its remarkable resistance against corrosion, aluminum proves to be apt for handling an array of chemicals. Moreover, its lightweight nature facilitates effortless installation and maintenance procedures. Furthermore, aluminum possesses commendable thermal conductivity, thereby enabling efficient heat transfer within chemical processes. Nonetheless, it is crucial to contemplate the distinctive demands imposed by the chemicals being conveyed and seek guidance from specialists to guarantee the selection of aluminum sheets equipped with indispensable properties and compatibility with the chemicals to be employed within the piping system.

- Q: Are aluminum sheets suitable for architectural applications?

- Yes, aluminum sheets are suitable for architectural applications. Aluminum is a versatile material that offers numerous advantages for architectural projects. It is lightweight, yet strong, making it easy to handle and install. Its corrosion-resistant properties make it well-suited for outdoor applications where it is exposed to the elements. Aluminum sheets can be easily formed into various shapes and sizes, allowing for creative and innovative architectural designs. They can be used for cladding, roofing, facades, and interior applications such as ceilings, partitions, and decorative elements. Additionally, aluminum sheets are available in a wide range of finishes, including anodized, painted, or coated, providing architects with the freedom to choose the desired aesthetic for their projects. These finishes can enhance the durability and color retention of the material, ensuring long-term performance and minimal maintenance requirements. Moreover, aluminum is a sustainable material as it is fully recyclable and has a low carbon footprint compared to other metals. This aligns with the increasing focus on environmentally-friendly construction practices in the architectural industry. In summary, aluminum sheets are highly suitable for architectural applications due to their lightweight, strength, corrosion resistance, versatility, range of finishes, and sustainable attributes. Architects can confidently choose aluminum sheets to create visually appealing and durable structures.

- Q: This question asks about the structural integrity and suitability of aluminum sheets for use in the construction of high-rise buildings.

- <p>Aluminum sheets are not typically used as the primary structural material in high-rise buildings due to their lower strength compared to steel and concrete. However, aluminum is known for its high strength-to-weight ratio, making it suitable for non-structural applications such as facades, window frames, and roofing. In high-rise construction, aluminum can be used in combination with other materials to provide a lightweight and aesthetically pleasing exterior while maintaining structural integrity with stronger materials like steel and concrete.</p>

- Q: What is the density of 101 aluminum sheets?

- The density of 101 aluminum sheets cannot be determined without knowing the dimensions and weight of each individual sheet.

- Q: What is the typical thermal expansion coefficient of aluminum sheets?

- Aluminum sheets generally possess a thermal expansion coefficient of approximately 23.1 x 10^-6 per degree Celsius. Consequently, with each degree Celsius rise in temperature, the length of an aluminum sheet will expand by roughly 23.1 millionths of its initial length. However, it should be acknowledged that this figure might slightly differ based on the particular alloy and processing circumstances of the aluminum sheet.

- Q: why is copper sheet but not aluminum sheet that becomes the negative pole after putting copper sheet and aluminum sheet connected with wire into concentrated nitric acid?

- it may be that aluminum won't react with concentrated nitric acid.

- Q: I am engaged in line cutting, because the cut aluminum plate conductive block wear more fierce, molybdenum wire is often broken card, I do not know that heroes have unique skills, say, we share. Thanks.

- The contact position between the conductive block and the electrode wire is often changed

Send your message to us

Wholesale Colored Aluminum Sheets - HD Aluminium Metal Art Pictures Print on HD Aluminium Metal Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 carton

- Supply Capability:

- 20000 carton/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords