14 Gauge Solid Core Polyethylene Insulated Construction Quality Multi-Purpose Wire

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

14 Gauge Solid Core Polyethylene Insulated Construction Quality Multi-Purpose Wire

1. Structure of 14 Gauge Solid Core Polyethylene Insulated Construction Quality Wire:

14 Gauge Solid Core Polyethylene Insulated Wire is made with choice mild steel, through wire drawing, wire galvanizing and other processes. Galvanized iron wire has the characteristics of thick zinc coating, good corrosion resistance, firm zinc coating, etc.

14 Gauge Solid Core Polyethylene Insulated Wire can be supplied in the form of coil wire, spool wire or further processed into straightened cut wire or U type wire. It is mainly used in construction, express way fencing, binding of flowers and wire mesh weaving.

2. Main Features of 14 Gauge Solid Core Polyethylene Insulated Construction Quality Wire:

• Antirust

• Shiny silvery color

• High strength

• Durable

• Versatile

• Good visual effect

3. 14 Gauge Solid Core Polyethylene Insulated Construction Quality Wire Images

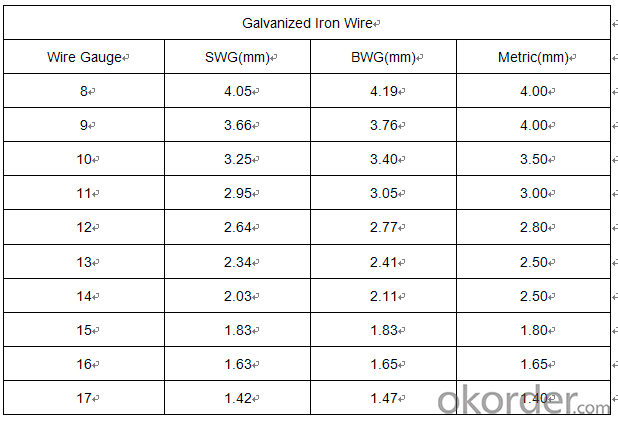

4. 14 Gauge Solid Core Polyethylene Insulated Construction Quality Wire Specification

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

① How about your products?

One of the most biggest manufacturer & supplier of wires and wire mesh, is a large-scale professional 14 Gauge Solid Core Polyethylene Insulated Wire factory in China. Annually more than 10000 tons wires and wire mesh are exported to markets all over the world.Different kinds of wires and mesh are available according to customer’s requirements.

② How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;Our company has good marketing network and abundant operation experience. Galvanized Iron Wire are sold to all parts of the country, at the same time, exported to Southeast Asia,The management theory is based on sincerity, keeping forging ahead. We have accumulated a whole set of marketing experience, having already become a local leader engaged in steel products.

③ How long can we receive the product after purchase?

In the purchase of 14 Gauge Solid Core Polyethylene Insulated Wire within three working days, We will arrange the factory delivery as soon as possible. The pacific time of receiving is related to the state and position of customers. Commonly 15 to 20 working days can be served.

- Q: Ok, i want to make a flash gun. I made one before with my cousin, but it broke. I remember what i used to make it, and how to make it, i just need the names of the wires and parts i need. How I made it: I had a battery connected to a wire that connected to a tube that had a special wire in there that heated up when i pressed a button. I would put flash paper in there, and a flame would shoot out. I need to know the name of that wire, I also need to know where to put the button on the wire connected to the battery. A link to a picture, or a detailed explanation would be really cool!Thanks!Nick

- That okorder The circuit is simple. The parts are the battery, some regular wire, a push-button switch, and the nichrome wire. Connect one end of the short piece of nechrome wire to one end of a wire. Connect that end to one of the battery terminals. Connect a second piece of wire between the other battery terminal and one side of the switch. Connect a third piece of wire from the switch to the other end of the nechrome wire. When the button is pushed, the wire should heat up.

- Q: I'd like to know what quot;wiremeans when it refers to computers. Is it the computer itself or the Internet?

- Wire is an old term. Way back in the day, many many moons ago, in the day of cowboys and Indians, there was an invention called the telegraph. Telegraphs are connected (or network as we say nowaday) by electrical wires. News and latest info are sent to the telegraphs through these wires. The postmaster received the latest info and breaking news from out of town through this contraption. He then handed the info over to the writers and said: This just came over the wire! or This just came across the wire! So through the years, over the wire and across the wire meant: The latest breaking news or info just published or broadcasted.

- Q: why is neutral wire.explain plz

- Any electrical circuit must have at least 2 wires for household service. These can be a hot leg and a neutral, or they can be two hot leads. This is typical for a split-phase 240/120 volt service. The neutral wire is the center tap of the transformer winding supplying the split-phase service. The neutral connection point at the transformer is the center tap of the transformer winding. The household system will carry as much of the total load in the 240 volt wires as possible, limited by the actual configuration of the wiring. And the only current carried in the neutral from your circuit breaker panel to the transformer is the unbalanced portion of the total load. The neutral wire in individual circuits from the circuit breaker panel always carries the same current as does the hot leg wire. The neutral is needed for single circuit runs from the circuit breaker panel to the loads. If you have a perfectly balanced load on both hot legs, you would not need a neutral from the circuit breaker panel to the transformer winding. But perfectly balanced conditions are seldom seen in the average home.

- Q: need to know how to properly wire this amp in a truck

- wow I have never heard of this amp until u mentioned it. the ratings seem good. ur best option would be to call sonic electronics have them send you a manual on how to wire this amp. they sell this amp. I mean u ask how to properly wire it. wire it to get power ? or to the woofers ? red wire + goes to your battery. black wire - goes to your ground (not your battery) to the frame of ur vehicle. then u need a blue wire, your remote this wire goes to ur stereo's remote wire it should be the same color or it will be marked. but if u do not know how to hook up an amplifier u should go to a professional shop due to the fact if u improperly hook ur amp up YOU CAN START A FIRE IN YOUR CAR.

- Q: how do i wire a dual 2 ohm sub to an amp at 2 ohm

- actually tc your almost right. yes 1 and 4 are the ohm loads of the speaker itself. but if your talking mono thats all you can achieve. on 2 channel amps when you bridge them your talking ohm drop again. so if you have one dvc 2 ohm wired in series and then bridged to the amp your looking at a 2 ohm load

- Q: function of a fire-wire for backing up data

- a firewire is just a port on your computer, mind you they are currently slightly faster then a usb. But what helps do a backup is the program you have on your computer, not the connection to the computer.

- Q: I know that there are wired routers, and wireless routers. Do wired routers do the same thing as wireless routers, without wireless capabilities?

- Most if not all wireless routers also work wired! Nearly all of them have at least four wired ports. The access point is the wireless connector, it just connects wireless capable machines to the exact same point within the router as the wired plugs do. A Wired router does not have the internal access point. With a wired router you can add wireless ability by simply adding an access point to them. The AP (access points) cost about as much as a full wireless router so you don't see them used very often but they are available. All the wireless does is eliminate the need for a local cable. Really that's all it does. Any computer connected to a router is connected to the router, wired or wireless makes no difference, although as a general statement the wired machines will be faster! So yes wired and wireless routers do exactly the same thing, they route local traffic for several machines to one broadband connection.

- Q: I made a kill switch for my car. All I need to do now is cut the wire that goes into my engine control module and join it with the switch I made. Would it be fine if I just use wire nuts or some sort of tape to join the wires instead of soldering? The instructions say quot;Step 6: Attach the killswitch wires one to each side of the wire you just cut. Step 7: Tape up all new connection.quot;It says to tape the new connections, but should I use exactly?

- Twisted wires can separate with the daily rattle and bumps of a car. I would crimp or solder it along with a shrink tube to secure it.

- Q: I know that most wire is copper, however, I found this wire that is silver in color. So that got me to thinking, what other metals are used in wire, and, are they all non-magnetic?

- It was made of tin and copper alloy. Outside coated with silver color tin to prevent rusty. This alloy is non magnetic. Other type wire or special cable were made with strand steel + copper like high voltage power line. Or like TV cable uses aluminum jacket shield copper coaxial cable.

- Q: there is a loose wire in my labtop charger wire. can i fix it or prevent it from happening.

- Loose wires just happen - from the way a cable is bent, moved, stored,wrapped, etc... I think (providing it doesn't happen right after you get the product) that it's pretty much normal wear and tear over time. You could try to repair it, but it would involve removing the cable sheath and re-attaching the loose wire which may need soldering. You're probably better off just buying a charger. In my experience, cables tend to last longer if you don't tightly wrap or twist them during storage; I generally just loosely fold them.

Send your message to us

14 Gauge Solid Core Polyethylene Insulated Construction Quality Multi-Purpose Wire

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords