Aluminum Siding Sheets - 1100-H24 Aluminium Sheet and Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 9 m.t

- Supply Capability:

- 3000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

Cold rolled aluminum sheet ,The detailed grade are as follows: 1010, 1050,1060,1100, 2024, 3003, 3005, 3105, 5052,5754,5083,6061,6063,8011, etc.

The temper is include H14, H22, H24, H44,H112,H114,etc.we have a good reputationin the field of aluminium material, besides, we are one global 500 enterprise, so you can really feel free for our production quality, if you are interested in any of our products, feel free to show us your detailed inquiries later, we give you best price, etc.

2. Main features of the product

a.Competitive price

b.Frist-Class Service.

c. Shortest service.

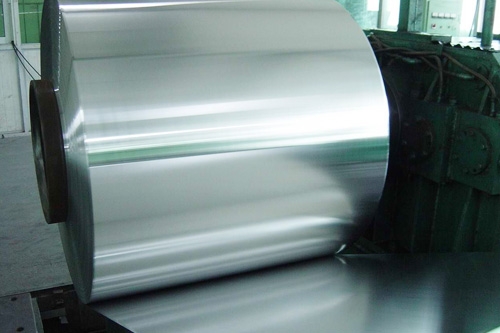

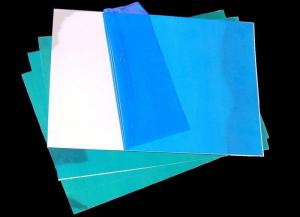

3. Image.

4. Product detailed sizes:

1000mm*2000mm,1100mm*2200mm,1200mm*2400mm,1220mm*2440mm,1500mm*6000mm,

1250mm*2500mm,1500mm*3000mm, etc.

5. FAQ:

What is the width range?

---It is from 1000mm to 2500mm, etc.

where is your client from?

----normally they are from UAE, ARAB, SINGAPORE, INDONESIA, ETC.

How many tons did they order in one year?

---normally it is around 9000 tons totally.

what is your MOQ now?

---normally it is around 5 tons/eah size.

how often did client place one order yet?

---it is around 1 month, etc.

what is your mainly products?

---Normally they are aluminum sheet, aluminum coil, chekcered sheet, mirror finish sheet, etc.

On the material terms: the cost price of aluminum is five times more than the cost price of iron, it is to count the cost of recycling, a price of aluminum is a hair, a tin price is 2 points, chose the high cost of embossing aluminum evaporator because the aluminum evaporative cooling effect is best, ordinary refrigerator uses wire tube evaporator in order to save costs, cut corners!

Embossed aluminum embossed aluminum plate and can be referred to as: aluminum plate on the basis of belonging through the rolling process in a variety of patterns formed on the surface of aluminum products, is widely used, and mainly used in packaging, construction, walls, and so on.

Aluminum refers to aluminum or aluminum alloy material processed into (cut or sawn) obtained by pressure rectangular cross section, material thickness uniform rectangular international customary to more than 0.2mm thickness, 500mm or less, 200mm width above, aluminum length 16m or less called aluminum sheet aluminum sheet, 0.2mm or less as aluminum foil, a width of less than 200mm row material or strip (of course with the progress of large equipment, the widest 600mm can be achieved exclusive material will be more).

- Q: Can aluminum sheets be used in electrical applications?

- Aluminum sheets have the capability to be employed in electrical applications. Due to its adeptness in conducting electricity, aluminum is frequently utilized in diverse electrical components and applications. In power transmission lines, bus bars, and electrical enclosures, aluminum sheets are frequently employed as conductive materials. Moreover, their exceptional thermal conductivity properties make them valuable in the production of capacitors, transformers, and heat sinks. Furthermore, aluminum sheets are lightweight and resistant to corrosion, rendering them appropriate for electrical applications where weight and durability are crucial considerations.

- Q: Are the aluminum sheets suitable for marine vessel construction?

- Yes, aluminum sheets are highly suitable for marine vessel construction. Aluminum possesses excellent corrosion resistance properties, making it ideal for use in saltwater environments. It is lightweight yet strong, providing a great balance between durability and weight savings. This allows for increased fuel efficiency and higher payload capacity. Additionally, aluminum is easy to fabricate, weld, and repair, making it a preferred choice for shipbuilders. Its high strength-to-weight ratio, along with its ability to withstand extreme temperatures, also makes it suitable for various marine applications, including hulls, decks, superstructures, and other structural components. Overall, the use of aluminum sheets in marine vessel construction offers numerous advantages, making it a popular choice in the maritime industry.

- Q: Im wondering as to how i darken the slide and frame of an airsoft 1911 pistol. I polished off all the black paint and exposed the chromish aluminum. I have some ideas to darken the metal but not sure. Maybe using olive oil and heating it up but im afraid i might warp the metal. I want it to come out sort of like a greyish gunmetal. Anybody know of a good process to give that worn out war like effect to the gun without painting it?

- Darken Aluminum

- Q: Is it possible to use aluminum sheets as a material for exterior walls in regions with cold climates?

- <p>Yes, aluminum sheets can be used for exterior walls in cold climates. Aluminum is a durable and lightweight material with good thermal conductivity, which can be beneficial for heat transfer. However, it's crucial to use insulated aluminum panels or combine aluminum with insulation materials to prevent heat loss and maintain indoor comfort. Proper design and installation are essential to ensure the building envelope's thermal performance and structural integrity in cold weather conditions.</p>

- Q: Do 101 aluminum sheets have any specific sound or vibration damping properties?

- Yes, 101 aluminum sheets have specific sound and vibration damping properties. Aluminum is known for its excellent damping characteristics, meaning it can effectively absorb or dampen vibrations and reduce noise levels. This is due to its high density and stiffness, which allow it to dissipate vibrational energy. Additionally, aluminum sheets can be further enhanced by applying sound-damping coatings or treatments, such as adhesive-backed damping sheets or constrained layer damping materials. These treatments can further improve the sound and vibration damping properties of 101 aluminum sheets, making them a popular choice in various industries where noise reduction and vibration control are important considerations, such as automotive, aerospace, and construction.

- Q: What are the primary components that make up aluminum sheets?

- <p>Aluminum sheets are primarily composed of aluminum, which is a lightweight and malleable metal. They are made from pure aluminum or aluminum alloys, which may include small percentages of other elements to enhance specific properties such as strength, corrosion resistance, or workability. Common alloying elements include copper, magnesium, manganese, silicon, and zinc. The exact composition varies depending on the specific grade of aluminum and its intended use. Pure aluminum is soft and not commonly used for sheets; instead, alloys are preferred for their improved strength and durability.</p>

- Q: This question asks for methods to determine the reliability of a supplier for aluminum sheets.

- <p>To determine if your supplier is reliable for supplying aluminum sheets, consider the following: Check their track record and customer reviews for consistency and quality. Assess their industry certifications, such as ISO standards, which indicate commitment to quality management. Evaluate their supply chain transparency and their ability to meet delivery timelines. Look into their financial stability to ensure they can sustain operations. Request samples to test the quality of their aluminum sheets. Finally, communicate openly with them to gauge their responsiveness and professionalism.</p>

- Q: Can aluminum sheets be used for insulation?

- Yes, aluminum sheets can be used for insulation. Aluminum is a good conductor of heat and electricity, so it can effectively reflect and block thermal energy. Aluminum foil, for example, is commonly used as a radiant barrier in insulation systems. It helps to prevent heat transfer by reflecting radiant heat away from the building, thus reducing the amount of heat that enters or escapes through the insulated areas. Additionally, aluminum sheets can also be used as a vapor barrier to prevent moisture from penetrating into the insulation, which helps to maintain its effectiveness. Overall, aluminum sheets can be a cost-effective and efficient option for insulation purposes.

- Q: Can aluminum sheets be used for lithographic printing?

- Yes, aluminum sheets can be used for lithographic printing. Lithographic printing, also known as offset printing, relies on the principle that oil and water do not mix. Aluminum plates are used as the printing surface in lithography because they can retain an image when treated with a combination of chemicals. The image areas attract ink, while the non-image areas repel it. This allows for high-quality and precise printing.

- Q: What is aluminum sheet material L2?

- L2 is the name of the brand of aluminium plate in our country, which is the 1060 brand now!L1 is 1070L2 is 1060L3 is 1050L4 is 1030L5-1 is 1100And LF-21, or 3003, LF-1, or 3004! Wait

Send your message to us

Aluminum Siding Sheets - 1100-H24 Aluminium Sheet and Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 9 m.t

- Supply Capability:

- 3000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords