Handi Foil Aluminum Foil Sheets - 1100-H22 Aluminium Sheet and Plates

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 9 m.t

- Supply Capability:

- 3000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

Cold rolled aluminum sheet is widely used in the field of construction field and decoration field, etc.

There are many different grades, such as: 1000 series, 2000 series, 3000 series, 5000 series, 6000series, etc. The detailed grade are as follows: 1010, 1050,1060,1100, 2024, 3003, 3005, 3105, 5052,5754,5083,6061,6063,8011, etc.

The temper is include H14, H22, H24, H44,H112,H114,etc.

Have you ever imported aluminium sheets from China before?

if you are interested, please don't hesitate to contact us later.

2. Main features of the product

a. Competitive price

b. Frist-Class Service.

c. Shortest service.

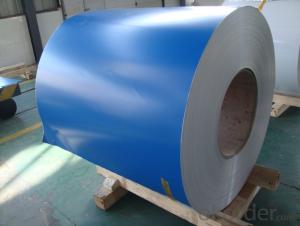

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438mm,1220mm*2440mm, 1250mm*2500mm,1500mm*3000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or else.

what is the width range and lengt range ?

---It is from 1000mm to 2500mm & from 2000mm to 6000mm, etc.

which countries have you ever export?

---we ever export goods to UAE, USA, AMERICA, ENGLAND, ETC.

How many tons did you export in each year?

---it is around 9000 tons totally.

what is your MOQ?

---Normally it is around 5 tons/each size.

Decorative aluminum sheet and aluminum alloy pressure plate or smallpox Kouban, aluminum, aluminum alloy as raw material, through cold rolling pressure processed into various sections of the sheet metal.

(1) Decorative aluminum sheet: decorative aluminum sheet is the antirust aluminum alloy billets. With special pattern and rolling, beautiful patterns, not easy to wear and slip resistance good. Strong corrosion resistance. Easy to rinse, through surface treatment can get different colors, decorative pattern sheet formation, size of precision cutting, easy to install. Widely used in wall decoration and staircases of the shoe board, and so on.

(2) Decorative aluminum sheet honeycomb core composite board, honeycomb core aluminum alloy composite plate of the surface layer is 0.2~0.7mm aluminum alloy sheet, the center layer with aluminum foil, glass cloth or fiber made of honeycomb structure, aluminum plate surface spraying with colored polymer protective coatings -- poly vinylidene fluoride, in composite plate of the outer surface of which is coated with stripping of plastic protective film, sheet metal in the processing and installation process is not damaged by. Aluminum alloy honeycomb core composite board as a senior decorative materials, used for a variety of architectural curtain wall system, but also for indoor walls, roof, ceiling, column, etc. the project site.

(3) Decorative aluminum sheet and pressure plate: it is widely used in the world of new decorative material and its soil to used for wall decoration, but also can be used for roof decoration. The surface after the chemical treatment can have a variety of colors, good decorative effect and a strong reflection of sunlight. Very durable, when used in the atmosphere for 20 years without replacement, dismantlement and removal of corrugated board can still continue to use.

(4) Decorative aluminum sheet, decorative aluminum sheet is according to the acoustics principle, using a variety of different perforation ratio in order to eliminate the noise, the material can be according to need to play to choose, commonly used is rust proof aluminum and anodized aluminum. The material is characterized by light weight, high strength, high temperature and high pressure, corrosion resistance, fire prevention, moisture, good chemical stability. Beautiful shape, elegant color, three-dimensional sense of strong, good decorative effect, the assembly is also very simple.

- Q: Are aluminum sheets suitable for electrical enclosures?

- Aluminum sheets are indeed suitable for electrical enclosures. With their lightweight and durable composition, they possess excellent conductivity and resistance to corrosion. Furthermore, their exceptional heat dissipation capabilities make them perfect for enclosures that house electrical components. Additionally, aluminum is easily manipulated, allowing for customization in terms of shape and size. To enhance their resistance to environmental elements such as moisture, dust, and chemicals, aluminum sheets can be coated or anodized. Overall, aluminum sheets offer a dependable choice for electrical enclosures, providing both electrical and mechanical properties while ensuring the protection of sensitive electrical equipment.

- Q: How do aluminum sheets perform in terms of thermal insulation?

- Aluminum sheets are not effective in terms of thermal insulation. Due to their high thermal conductivity, aluminum sheets allow heat to easily transfer through them. This means that they are not able to effectively block or resist the transfer of heat, resulting in poor thermal insulation properties. If thermal insulation is the primary concern, other materials such as fiberglass, foam, or mineral wool would be more suitable choices.

- Q: Are aluminum sheets suitable for hydraulic applications?

- Yes, aluminum sheets can be suitable for hydraulic applications. Aluminum is a lightweight and corrosion-resistant material, making it an excellent choice for hydraulic systems. It offers good thermal conductivity, which helps in dissipating heat generated during hydraulic operations. Additionally, aluminum sheets can be easily formed and machined to meet specific design requirements, making them adaptable for various hydraulic components such as reservoirs, tanks, and piping systems. However, it is important to consider the pressure and temperature requirements of the hydraulic application, as aluminum has lower strength and melting point compared to other metals like steel.

- Q: Where does China make aluminum plate?

- In many parts of the country have aluminum factory, the old state-owned enterprises have 101, SWA aluminum plant, located in the southwest, northeast china. The emerging aluminum processing base in Henan, due to resource advantages, the largest aluminum factory, the price is relatively low.

- Q: Can 101 aluminum sheets be purchased in small quantities or only in bulk?

- Aluminum sheets can typically be purchased in both small quantities and in bulk. While it may depend on the specific supplier or retailer, many offer aluminum sheets in various sizes and quantities to meet the diverse needs of customers. Whether you require a few sheets for a small project or a larger quantity for industrial purposes, it is worth exploring different suppliers to find the option that best suits your requirements.

- Q: how would you use aluminum to extract silver from film?just ideas please

- The silver in film is part of a silver salt (silver halides.) It is a very very small amount, probably less than 1 cent worth per roll. You would be a lot better off selling the film than trying to extract the silver from it. If you are hell bent on it, the first step is to expose the film to light. This will break the silver from the halides. Then you can go about trying to figure out how to get the silver apart from the film. I am sure it is possible, but it would involve a lot of work. I imagine you you would spend about $100 on ever $1 worth of silver you could extract.

- Q: Do the aluminum sheets come with a protective coating?

- Indeed, the aluminum sheets are accompanied by a protective coating, which is skillfully applied in order to safeguard against any potential scratches, corrosion, or other forms of damage that may occur during the process of transportation and handling. This meticulous coating process guarantees that the aluminum sheets are delivered to our cherished customers in an immaculate state.

- Q: What is the weight per square foot of 101 aluminum sheets?

- The weight per square foot of 101 aluminum sheets varies depending on the thickness of the sheets. Please provide the thickness of the aluminum sheets to determine the weight per square foot accurately.

- Q: How do you clean aluminum sheets?

- To clean aluminum sheets, you can start by rinsing them with water to remove any loose dirt or debris. Then, create a mixture of mild dish soap and warm water. Use a soft cloth or sponge to gently scrub the aluminum sheets with the soapy solution. Avoid using abrasive cleaners or scrub brushes, as they can scratch the surface of the sheets. Once you've thoroughly cleaned the sheets, rinse them again with water and dry them with a clean towel or cloth.

- Q: have been taking an over the counter Antacid consistently for the past 8 years as a daily source of extra calcium per the bottle. Now, I am getting many nerve problems, similar to Lou Gehrig's disease. I am a healthy 38 year old male who excersises, eats right and is generally health conscious. I am concerned that unknowingly I have toxified my body with the aluminum that apparently is in Antacid. I did not know this until now or of course I would not have gone any where near it.Can taking Antacid lead to nerve problems such as Lou Gehrig's disease?

- Aluminum okorder /

Send your message to us

Handi Foil Aluminum Foil Sheets - 1100-H22 Aluminium Sheet and Plates

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 9 m.t

- Supply Capability:

- 3000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords