Smooth Aluminum Siding Sheets - 1100-H14 Aluminum Sheet and Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 9 m.t

- Supply Capability:

- 3000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

1010, 1050,1060,1100, 2024, 3003, 3005, 3105, 5052,5754,5083,6061,6063,8011, etc.

The temper is include H14, H22, H24, H44,H112,H114,etc.

2. Main features of the product

a.Competitive price

b.Frist-Class Service.

c. Shortest service.

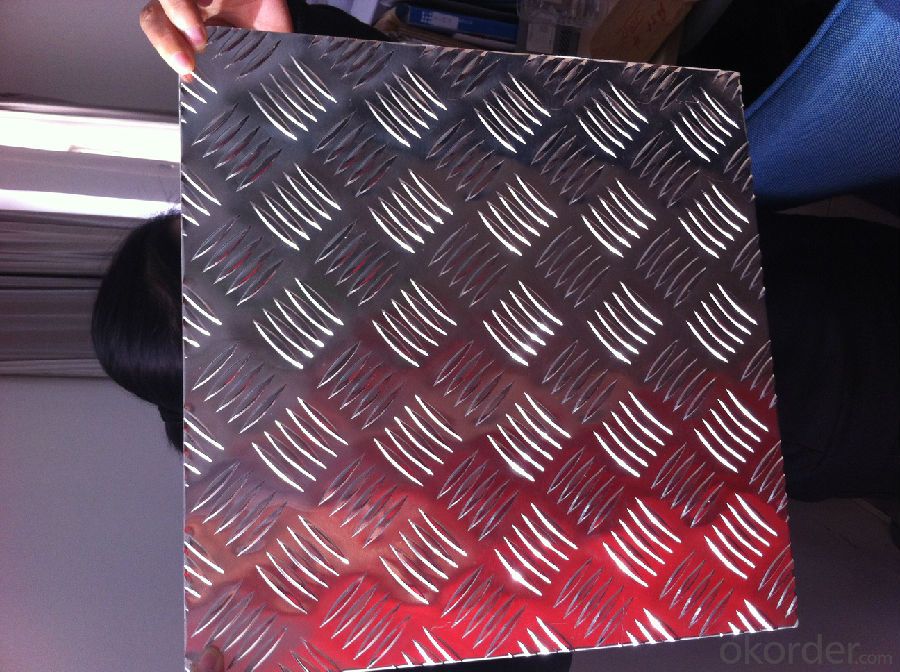

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438mm,1220mm*2440mm, 1250mm*2500mm,1500mm*3000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 1000mm to 2500mm, etc.

What is the length range:

---It is from 2000mm to 6000mm, etc.

What is the MOQ for your products yet?

---Normally it is around 5 tons/each size.

How many tons did you export in one year?

---Normally it is around 9000 tons totally.

Where is your client from?

---Normally it is from Japan, USA, ENGLISH, SINGAPORE, ETC.

What is your mainly products?

---Normally they are aluminum sheet, checkered sheet, mirror finish aluminium sheet, aluminum casting coil, etc.

- Q: Can aluminum sheets be coated with other materials?

- Yes, aluminum sheets can be coated with other materials. Aluminum is a versatile metal that can be easily coated with various substances, such as paints, lacquers, polymers, and specialty coatings. These coatings can enhance the appearance, durability, corrosion resistance, and thermal or electrical properties of the aluminum sheets.

- Q: What are the different surface finishes available for aluminum sheet?

- There are several surface finishes available for aluminum sheet, including mill finish, brushed finish, anodized finish, and painted finish.

- Q: As for graphite and aluminum sheet, which one has a better thermal conductivity?

- aluminum sheet

- Q: 1mm the aluminum plate is pulled to the height of 45mm. Can I pull it out at 1? How much space should I put in?

- How much clearance does aluminum plate stretch?The clearance value of the stretched aluminum plate is =1.3~1.4t (first stretch), 1.15~1.2t (second times stretch), and 1.1t (last stretch). The tensile properties of aluminum sheets are inferior to those of low carbon steel, and they are easily broken when stretched. The tensile height 45mm depends on the diameter of the drawing piece.A cylindrical part of a large cross-sectional area from a material to a small cross section is called a tensile coefficient. That is, the ratio of the cross-sectional area to the cross-sectional area before stretching, i.e., m=A0/An-1. For cylindrical parts, m1=d1/D0, the coefficient of the first stretch can be around 0.5, i.e., the diameter after the first stretch is 1/2 of the blank diameter before the drawing. In the future, the tensile coefficients are usually around 0.7~0.8. The calculation of drawing blank, roughly calculate the blank size according to the principle of equal area of the blank before and after the drawing.

- Q: Is it possible to utilize aluminum sheets for crafting distinctive architectural structures?

- <p>Yes, aluminum sheets can be used to create unique architectural designs. Known for their strength, durability, and lightweight properties, aluminum sheets are ideal for various architectural applications. They can be easily shaped and cut to fit specific design requirements, offering flexibility in design and construction. Additionally, aluminum's resistance to corrosion and weathering makes it a sustainable choice for long-lasting structures. Architects often use aluminum for facades, roofing, and other exterior elements due to its modern aesthetic and low maintenance needs.</p>

- Q: What specific conditions or regulations must be met when using aluminum sheets in commercial construction?

- <p>Yes, there are special requirements for using aluminum sheets in commercial buildings. These include adherence to building codes and standards for fire resistance, structural integrity, and weather resistance. Aluminum sheets must meet specific thickness and strength requirements depending on the application. They also need to comply with environmental regulations regarding sustainability and recyclability. Additionally, for aesthetic purposes, the finish and color of the aluminum sheets should be in line with architectural design guidelines. It's crucial to consult with architects, engineers, and local building authorities to ensure all requirements are met.</p>

- Q: Can aluminum sheet be used in marine environments?

- Yes, aluminum sheet can be used in marine environments. Aluminum is a popular material choice for marine applications due to its excellent corrosion resistance. It forms a protective oxide layer on its surface, which helps to prevent further corrosion even in saltwater environments. Additionally, aluminum is lightweight, which makes it an ideal choice for marine applications where weight reduction is crucial. Aluminum sheet is commonly used in boat hulls, decks, and other marine structures due to its durability, strength, and resistance to corrosion.

- Q: A solid aluminum sphere has a mass of 83 g.Use the density of aluminum to find the radius of the sphere in inchesExpress your answer using two significant figures.I can't figure this out :(

- Aluminum's density is about 2.7 grams per cubic centimeter. So a sphere with a mass of 84grams has a volume of about 31.111 cubic centimeters. You get this by dividing 84 by 2.7. Now that you know the volume, you can calculate the radius of the sphere. for a sphere, volume = 4/3 pi * radius to the third power. So 31.111 = 4/3 * (3.14...) * r^3. Divide both sides by 4/3 then divide both sides by pi and you get something like r^3 is 7.427. Then find the cube root of this to find your radius. I don't have a calculator, so someone should check the numbers.

- Q: Is it possible to purchase recycled aluminum sheets from a local supplier or manufacturer?

- <p>Yes, you can buy recycled aluminum sheets from local suppliers or manufacturers. Many businesses specialize in recycling and repurposing materials, including aluminum. To find a local supplier, you can search online directories or use business listing services. Additionally, contacting local recycling centers or metalworking businesses may provide leads on available recycled aluminum sheets. It's important to consider the quality, certifications, and environmental impact of the recycled materials when making your purchase.</p>

- Q: What are the common thicknesses of aluminum sheets used in construction?

- The common thicknesses of aluminum sheets used in construction vary depending on the specific application and requirements. However, some commonly used thicknesses include 0.032 inches (0.81mm), 0.040 inches (1.02mm), 0.050 inches (1.27mm), and 0.063 inches (1.60mm). These thicknesses are often used for architectural applications such as wall panels, roofing, and siding. Thicker aluminum sheets, such as 0.080 inches (2.03mm) and 0.125 inches (3.18mm), are also used in heavier construction applications such as structural components, support beams, and decking. It is important to note that these thicknesses are just examples and can vary depending on the specific project requirements and engineering specifications.

Send your message to us

Smooth Aluminum Siding Sheets - 1100-H14 Aluminum Sheet and Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 9 m.t

- Supply Capability:

- 3000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords