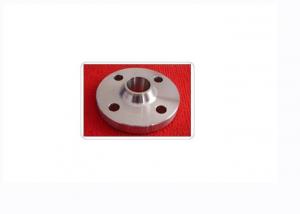

Welded Neck Flange

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 Tons m.t.

- Supply Capability:

- 5000 Tons per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

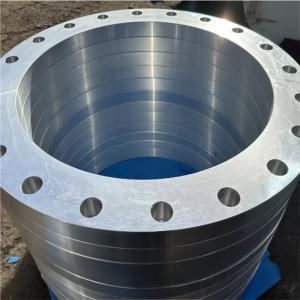

material for carbon steel, stainless steel and alloy steel, such as ASTM A105, A182, A350, A694, ST35.8, ST45.8, ST37.2, C22.8,

The production base total area is about 82,300 square meters.The annual production capacity is more than 9000 tons, with fine processing technology and advanced detection means.

The company has passed Rhine, Germany(TüV) ISO9001 quality management system certification , European pressure equipment and materials PED97/23/EC certification and German pressure equipment and materials AD2000-WO certification. It has also passed the pressure pipe components manufacturing safety registered certification of the State Quality Inspection Administration and classification societies certified .So a more effective guarantee is provided for the quality of the products.It has become the one of the enterprises firstly through the certification in the industry.It plays an important leading role in the industry.

The high-quality products are widely used in petroleum, chemical, metallurgy, electric power, ship, natural gas , pipeline industries and so on.It has won the users good evaluation.At the same time,the products are exported to Europe and the United States, the Middle East, Africa and South-East Asia regions and other countries.

- Q: What's the outer diameter of the DN100 standard flange, please? Galvanized pipe with DN100

- Flange outer diameter 220mmBolt hole distance 180mmBolt diameter 18mmFlange thickness 22mm

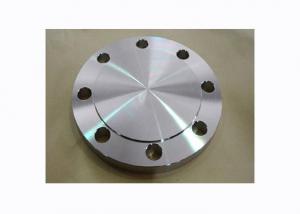

- Q: What's the difference between the flange and the flange cap?

- The biggest difference is that there is a hole in the middle of the flange and there is no hole in the middle of the flange cover

- Q: Flange blind plate production and installation should be fixed what quota ah?

- Use installation quota sixth book "process piping installation project", the implementation of flange installation project, apply to "sub -" as a unit of the quota, and then multiplied by factor 0.61.

- Q: What are the differences between the clamping and flange styles of valves?

- This problem, mainly refers to the butterfly valve in two forms, pairs of clamp and flange type:The clip butterfly valve (valve itself without flange) is a double headed bolt to connect the valve between the two pipe flanges. The clip butterfly valve is simple, small and light in weight and consists of only a few components. The utility model can be rapidly opened and closed only by rotating 90 DEG, the operation is simple, and the valve has good fluid control characteristics. The following is a manual clip on butterfly valve. The following is an electric butterfly valve:Turn left and turn right |Turn left and turn right |Flanged butterfly valves are flanged on the valve and bolted to both ends of the valve to connect the flanges to the pipe flanges. Sealing surface wear resistance, long service life. The utility model has the advantages of unique structure, flexible operation, labor saving, convenience, and high and low pressure without the pressure of the medium. Here is the manual flange butterfly valve, the following is the electric flange butterfly valve:Turn left and turn right |Turn left and turn right |On the clip and flange flange specifications are the same, just on the flange bolt valve with long length of 2 times the thickness of the valve flange nuts + +2 thick thick, without flange clampvalves itself; as long as the open bolt nut, then the pipe at both ends of the valve are not normal work.Bolt flange type with relatively short length of 2 times the thickness of +2 flange nuts, flange thickness "valve body flange and pipe paired by bolts, locking nut; when the flange bolt and nut end is removed, does not affect the normal operation of the other end of the pipe.

- Q: What's the function of the flange of the die?

- The flange and the flange Jack Tsui concentric, which plays the role of Jack Tsui and the injection molding machine on the nozzle alignment, machine design and flange specifications should be consistent with.1, flange (Flange), also known as flange, flange plate or edge. A flange is a part that is connected between the pipe and the pipe, used for the connection between the ends of the pipe. It is also used for the flange on the entrance and exit of the equipment. It is used for the connection between the two devices, such as the reducer flange. Flange connection or flange joint means that the flange, the shim and the bolt are mutually connected as a group of three detachable sealing structures. Pipe flanges are flanges used for piping in pipe installations. They are used on equipment and refer to the entrance and exit flanges of the equipment. The flange is lined with bolts to secure the two flanges. Gaskets for gaskets between flanges.2, sub threaded flange connection (threaded connection), flange welding flange and flange clamp. Flanges are used in pairs. Low pressure pipes can be made of wire flanges and welded flanges with pressures of more than four kilograms. Add a gasket between the two flanges and secure with bolts. Different pressure flange thickness is different, they use the bolt is also different. Water pump and valve, and in the pipe connection, these equipment parts of the equipment also made corresponding flange shape, also known as flange connection. Any connecting parts that are bolted and closed in the vicinity of the two planes are generally referred to as flanges, such as the connections of the ventilation ducts, which can be called flanges". However, this connection is only part of a device, such as flanges and pumps connected, it is not good to call the water pump flange parts". Relatively small, such as valves, can be called flanges".

- Q: What does the flange PL stand for?

- PL is the flange welding plate flangeWelding plate flange (PL):Flange for nominal pressure of not more than 2.5MPa steel pipe flange connection. The sealing surface can be made smooth, bump and tenon slot three. Flat welding flange smooth application of the largest. For mild medium conditions, such as low non clean air, low pressure circulating water.Flange classification:1, according to the chemical industry standard (HG): integral flange (IF), (Th), threaded flange welding plate flange (PL), neck flange (WN), hubbed flange (SO), socket welding flange, butt welding (SW) ring loose flange (PJ/SE), flat loose flange ring lining flange (PJ/RJ), (BL (S)), flange (BL).2, according to the petrochemical industry standard (SH): (PT), threaded flange welding flange flange (WN), (SO), socket welding flange (SW), loose flange, flange cover (LJ) (not note).3, according to the mechanical (JB) industry standard: integral flange, welded flange, welding plate flange, butt welding ring loose plate flange, welding ring loose plate flange, flange ring loose plate flange, flange cover.4, according to the national standard (GB): integral flange, threaded flange, flange, butt welding and hubbed flange hubbed socket welding flange, butt welding neck flanges, ring plate flange, butt welding ring loose plate flange, welding ring loose plate flange, flange ring loose plate flange, flange cover.

- Q: Who explains the difference between the injection molded flange, the injection molded joint and the injection molded flange joint?

- Barrel flange is also called big mouth is the first stage to tighten the screws, you are not clear

- Q: The difference between the welding and butt welding of flange

- Give you a plastic mark:Step 1: install the pipe, have you seen it?The second step: any of you saw a short knot down, but one must have a flange headThe third step: you have just saw the original welding back, and then the welding method is butt weldingThe weld flange is similar to the part you just welded back, except that the pipe is short and short, that is to say, there is a short short tube attached to the flange of the weld flange, and the short tube is welded to your pipe.Flange and pipe flange weld is also worn in the lap, is the pipe flange welding.The above is not a formal explanation, just to make you understand

- Q: Which valves should be fitted with flanges?

- What's your connection to the pipe design?.Common pipe connections include clamps, flanges, welds, threads, if you have flanges in your pipe. Then you'll need to buy a flanged connection

- Q: What's the flange joint?

- The flange of the JB/T4702 type B equipment has the requirement of the thickness of the cylinder joint connected with it, but it can not be rigid for the thickness of the whole cylinder. To this end, the standard specifies the length and length of a section of the tube to which it is attached. This is the short joint.If the design thickness calculated by the cylinder is less than the required thickness of the JB/T4702, a short joint should be used.If the design thickness calculated by the cylinder is greater than or equal to the required thickness of the JB/T4702, there is no need to use the short joint.

1. Manufacturer Overview

| Location | Shandong,China |

| Year Established | 2008 |

| Annual Output Value | |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe Central America Northern Europe Southern Europe |

| Company Certifications | ISO9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | qingda |

| Export Percentage | 81% - 90% |

| No.of Employees in Trade Department | |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 10,000-30,000 square meters |

| No. of Production Lines | 10 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | Low and/or Average |

Send your message to us

Welded Neck Flange

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 Tons m.t.

- Supply Capability:

- 5000 Tons per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords