Galvanized Iron Wire In Coil With High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

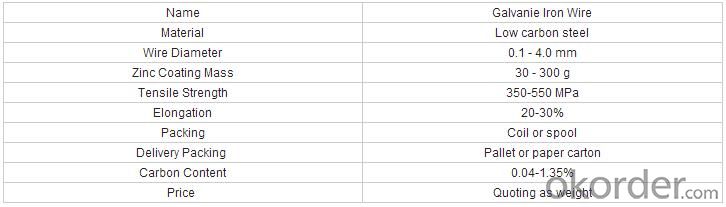

Specification

Material:

Galvanized Iron Wire

Cross Sectional Shape:

Round

Application:

Construction Wire Mesh

Type:

Galvanized

Wild in Width:

1.1M

Surface Treatment:

galvanized

Metal Wire Drawing:

Cold Drawing

Status:

In Hard State

Thickness:

Metal Thick Wire

Galvanized Technique:

Hot Dipped Galvanized,Electro Galvanized

Product description

Material: High quality low carbon steel

Processing And Character: Have been gone through the process of wire drawing, acid washing, rust removing, annealing and coiling, it offers excellent flexibility and softness.

Usage: Used in weaving wire mesh, construction, handicrafts, express way fencing mesh, packaging of products and other daily uses.

Specification: Hot dipped galvanized iron wire, BWG24-BWG8; Electric galvanized iron wire: BWG36-BWG8

Product show

Galvanized wire | |||||||

| Wire gauge size | SWG | BWG | |||||

| Inch | mm | Inch | mm | ||||

| 8 | 0.160 | 4.06 | 0.165 | 4.19 | |||

| 9 | 0.144 | 3.66 | 0.148 | 3.76 | |||

| 10 | 0.128 | 3.25 | 0.134 | 3.40 | |||

| 11 | 0.116 | 2.95 | 0.120 | 3.05 | |||

| 12 | 0.104 | 2.64 | 0.109 | 2.77 | |||

| 13 | 0.092 | 2.34 | 0.095 | 2.41 | |||

| 14 | 0.080 | 2.03 | 0.083 | 2.11 | |||

| 15 | 0.072 | 1.83 | 0.072 | 1.83 | |||

| 16 | 0.064 | 1.63 | 0.065 | 1.65 | |||

| 17 | 0.056 | 1.42 | 0.058 | 1.47 | |||

| 18 | 0.048 | 1.22 | 0.049 | 1.25 | |||

| 19 | 0.040 | 1.02 | 0.042 | 1.07 | |||

| 20 | 0.036 | 0.91 | 0.035 | 0.89 | |||

| 21 | 0.032 | 0.81 | 0.032 | 0.813 | |||

| 22 | 0.028 | 0.71 | 0.028 | 0.711 | |||

| 23 | 0.024 | 0.61 | 0.025 | 0.64 | |||

| 24 | 0.022 | 0.56 | 0.022 | 0.56 | |||

| 25 | 0.02 | 0.51 | 0.020 | 0.51 | |||

| 26 | 0.018 | 0.46 | 0.018 | 0.46 | |||

| 27 | 0.016 | 0.42 | 0.016 | 0.41 | |||

| 28 | 0.015 | 0.38 | 0.014 | 0.36 | |||

| 29 | 0.014 | 0.35 | 0.013 | 0.33 | |||

| 30 | 0.0124 | 0.32 | 0.012 | 0.31 | |||

| 31 | 0.012. | 0.30 | 0.010 | 0.25 | |||

| 32 | 0.011 | 0.27 | 0.009 | 0.23 | |||

| 33 | 0.010 | 0.25 | 0.008 | 0.20 | |||

| 34 | 0.009 | 0.23 | 0.007 | 0.18 | |||

| 35 | 0.008 | 0.21 | 0.005 | 0.13 | |||

| 36 | 0.0076 | 0.19 | 0.004 | 0.10 | |||

| 37 | 0.07 | 0.17 | |||||

| 38 | 0.006 | 0.15 | |||||

- Q: I just bought a new JVC CD player well my dad and I are trying to hook it all up, we went to auto zone and got all the parts we need, wiring harness and faceplate kit. We got all the wires stripped and hooked to the right ones except when we plug it in there is no sound CD player works just no sound. There is an extra little clip that has 4 extra wires that need to be hooked up and we KNOW that's what the problem is. If anyone knows where these wires belong please let me know or if you know where i can get a FREE wiring diagram that would be great!! Thank you!!

- Car Radio Battery Constant 12v+ Wire: Orange Car Radio Accessory Switched 12v+ Wire: The radio harness does not provide a switched power source. Run a wire to the fusebox or ignition switch harness for switched power. Car Radio Ground Wire: Black/White Car Radio Illumination Wire: Violet Car Stereo Dimmer Wire: Violet Car Stereo Antenna Trigger Wire: N/A Car Stereo Amp Trigger Wire: N/A Car Stereo Amplifier Location: Located under the center of the rear deck. Car Audio Front Speakers Size: N/A Car Audio Front Speakers Location: N/A Left Front Speaker Positive Wire (+): Tan Left Front Speaker Negative Wire (-): Gray Right Front Speaker Positive Wire (+): Light Green Right Front Speaker Negative Wire (-): Dark Green Car Audio Rear Speakers Size: N/A Car Audio Rear Speakers Location: N/A Left Rear Speaker Positive Wire (+): Brown Left Rear Speaker Negative Wire (-): Yellow Right Rear Speaker Positive Wire (+): Dark Blue Right Rear Speaker Negative Wire (-): Light Blue

- Q: Would crepe paper stick on chicken wire?

- Crepe paper needs an adhesive to make it stick to a surface, such as white glue. However, it gets messy once dampened, as the colors may bleed. Instead, I would consider working with paper mache or plaster gauzing strips, which would provide a strong skin over the chicken wire. Both can be primed with gesso then decorated with acrylic paints. If this is a sculptural piece you want to keep, we would also suggest varnishing it for protection.

- Q: Im installing a motion sensor which comes with 3 wires,red black and white and want to connect it to a indoor light that only comes with 2 wires white and black.How do I go about installing them and powering them?

- I don't know what the wires on the motion sensor are except red and black are your live wires, and white is your neutral. The two wires off your light are black is power and white is neutral. You should find the instructions for your motion sensor, it should tell you how to hook it up. Try searching for your model at yahoo or google.

- Q: how do i wire my sensor to my light

- Normally it is black wire to black wire, white to white and ground (copper) to ground.

- Q: Please help. I am trying to fit a new light into a house with old wiring.My new light just has a connection block with 1 blue wire and 1 brown wire. When I removed the old light there are 5 wires coming from the ceiling. 1 black and 1 red coming from one lead and 1 black and 1 red coming from the other. Any ideas how I wire this up. Many thanks.

- before to many Americans jump in - I have to say the colours you are quoting make me sure you are in the UK - so :- If there are only 4 wires (not 5 as you say at one point) then join the two reds together in a connector block and tape that up completely with insulating tape and make sure it is safe somewhere - many light fittings have an additional connection just for this purpose. Now connect the blue from the light to one black and the brown to the other black wire (it does not really matter which to which although purists may like you to find the true live for the brown) If however there are 5 wires you need to do a bit more investigation . EDIT - the two earth wires should be securely joined together to make sure that earth continuity is maintained throughout the rest of the house - then tape them up - preferably with green and yellow tape but black will do and tuck them back up into the ceiling as far away from the two reds as you can manage. ....

- Q: my old light fixture had 2 white wires (from ceiling) twisted together and connected to a screw, it also had a green wire (from ceiling)connected to it with a screw.no black wires were connected to light fixture although they are 3 wires in the ceiling taped off together.how do i test for hot wire, i got a tester that lights up.i got a new light fixture that has 3 wires, 1 wht 1blk and copper.i know the copper goes with green, white with white and black with black. so i untangled the black wires, and i connected one to new light.but now my new light doesnt turn off.so i know i by passed my switch.how do i test for hot wire....where does the hot wire go?is it possible one of the white wires is my hot wire and the other white whire my neutral....so help please, im confused and frustrated

- It sounds like the old fixture may have been improperly wired. It should not have had the green wire going to one side (screw) with the white wires going to the other side of the fixture. The green wire is normally a ground, and is only connected to the housing of the fixture - it's purpose is solely for safety, in case the hot side comes in contact with the metal fixture housing (it blows the breaker by design rather than being an electrocution hazard). Typically, the hot (black) wire is switched, and the neutrals bypass the switch. Your best bet is to search online for a wiring diagram for a switched light fixture, print it out and working with your test light, find the switched hot wire by measuring from each wire to the ground wire (for convenience only - hopefully it is really grounded) with the switch set in both directions. Note the results on the diagram, and that should help you sort it out.

- Q: what to do if i unhooked my starter without unhooking my battery and the hot and gound wire caught on fire

- Replace the cables, and chalk it up as a learning experience. Now you know why shops charge so much. They learn before doing.

- Q: Does anyone know what color the neutral safety wire is on a 1995 suburban? The one in the ignition harness.

- It is usually white, or sometimes gray.

- Q: Wires in the dash*Radio constant*Radio Switched*Radio illumination**please match these up with the options below**Wires on the stereo itself*Dashboard Light Dimmer Switch*Amplifier Remote or Power Antenna (Positive +)*(fuze) yellow memory (negative -)*(fuze) red 12v (positive +)if someone could please help that would be great-since the wires were replaced i cant go by color

- Car radio wire constant to stereo yellow memory. Car radio wire switched to stereo red 12v positive. Car radio wire illumination to stereo Dashboard Light Dimmer Switch. Don't forget to ground the black wire on the unit to the ground wire from the car harness. An extra ground strap to the chassis is a good idea also. If you don't have an amp or a power antenna, cap off the blue Remote/Antenna wire.

- Q: so im doing a custom buggy and i need so different colored wire im looking for a place to get lots of different colored wire for cheap

- Summit Racing...

Send your message to us

Galvanized Iron Wire In Coil With High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches