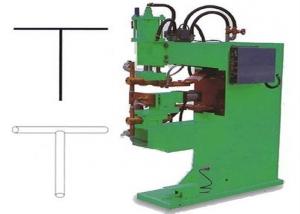

Multi Welding Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 1 Set per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

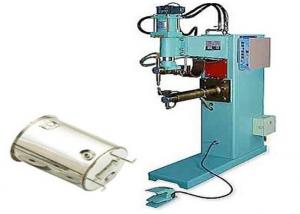

Condenser Welding Machine

1. Function update fast can compare with famous brand.

2. Long endurance design.

3. Many patents

Condenser Welding Machine Features :

1.Condensed type just needs 1/10-1/30 current if it is compared with alternative current type. It can make use of the power efficiently. It is a power-saved type welding machine.

2.Very less hot warp and oxidization save the processing in follow-up steps.

3.StabilityLess welding tolerance conforms to JIS vehicle specifications.

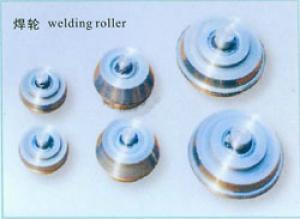

4.EconomyThe consuming parts such as copper electrode is very less, and power consumption is very less. It reduces the operation cost.

5.DurabilityThe pressure adding device and the semiconducting charge and the discharge circuits are considered to keep their superiority.

6.The key components are imported from Europe, the USA and Japan. Among them, the pneumatic components are made in Japan, and SCR (Silicon Controlled Rectifier) is a product made in Europe, the USA or Japan. The condenser is same as the condenser used in Japanese.

7.Machines. It is a storage type condenser for special use on instant charge and discharge. The control system is made of the USA or Japanese components.

In addition to above features, the non-iron metal and the different kind of metal can be soldered together. It doesn't need auxiliary material, but increases efficiency if it is compared with the conventional method of rivet and solder. It is very helpful for the enterprise to save material charge and the salary.

Discharge Pour Power Control Circuit Layout

The principle of condensing type resistor Welding machine

As Figure 1 shown, store the power needed for welding into the condenser. Then, discharge this power instantly into the welding container. It will discharge a large welding current. It is like to pump the water from a well to a bucket. Then, pour the water suddenly from the bucket.

Therefore, it just needs one tenth or less current to finish the work if it's compared with the alternative current type welding machine.Besides, the current of instant electricity discharge can be used efficiently. Its heat efficiency is better than other welding types.

The condenser can be charged 475V maximum. The charge voltage can be adjusted to meet the need of welding current. The charge voltage is controlled by semiconductor, so the charge voltage is not changed even if the voltage is unstable. You just need to set one time, and always have a fixed welding current for the welding needs.

Specification :

| Model | Rated Capacity | Rated frequency | Input voltage | Rated force | Electrode pressure | Cooling water |

| Specification | KVA | HZ | V | WS | Kgf | l/min |

| DJ-G05 | 0.5 | 50/60 | 220 | 300 | 10 | AIR |

| DJ-G10 | 1.0 | 50/60 | 220 | 500 | 90 | AIR |

| DJ-G15 | 1.5 | 50/60 | 220 | 750 | 150 | AIR |

| DJ-G30 | 3 | 50/60 | 220 | 1500 | 250 | 3 |

| DJ-G50 | 5 | 50/60 | 220 | 2500 | 300 | 3 |

| DJ-G70 | 7 | 50/60 | 220 | 3500 | 500 | 3 |

| DJ-G90 | 9 | 50/60 | 220 | 4500 | 500 | 5 |

| DJ-G110 | 11 | 50/60 | 220 | 5500 | 800 | 5 |

| DJ-G150 | 15 | 50/60 | 220 | 7500 | 800 | 6 |

| DJ-G200 | 20 | 50/60 | 220~440 | 10000 | 1000 | 6 |

| DJ-G250 | 25 | 50/60 | 220~440 | 12500 | 1200 | 7 |

| DJ-G300 | 30 | 50/60 | 220~440 | 15000 | 1400 | 8 |

|

Suitable for worldwide voltage, design & making according to local need. The machine shape is designed as per workpiece, ensuring its funcition. The capacity won't change. | ||||||

- Q: What is the influence of the cooling rate after welding on the mechanical properties of the weld?

- For second types of steels which are sensitive to temper embrittlement, slow cooling can lead to slow cooling embrittlement.

1. Manufacturer Overview

| Location | Taiwan,China |

| Year Established | 1973 |

| Annual Output Value | US$5 Million - US$10 Million |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Mid East Eastern Asia Western Europe |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | 71% - 80% |

| No.of Employees in Trade Department | 3-5 People |

| Language Spoken: | English, Chinese, Japanese |

| b) Factory Information | |

| Factory Size: | 5,000-10,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered Design Service Offered |

| Product Price Range | Average |

Send your message to us

Multi Welding Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 1 Set per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords