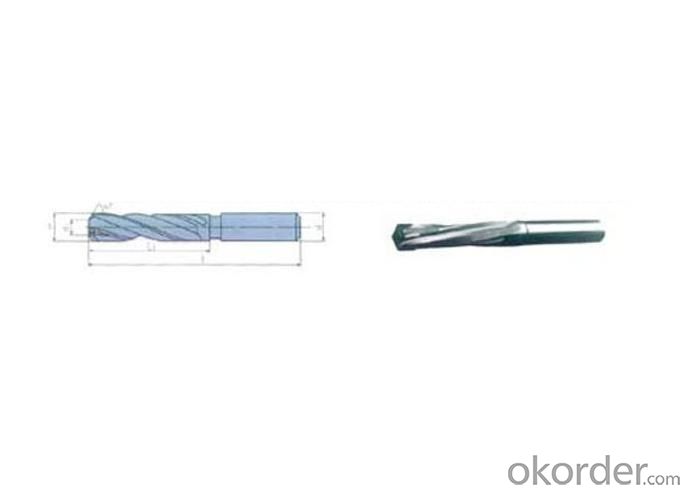

Flute Reamer

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Pieces pc

- Supply Capability:

- 1000 Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

1.Good quality

2.Welding hard alloy hole machining tools

3.Competitive price

4.Excellent after-sales service

Flute Reamer

Order No. |

D(h8) |

d(h9) |

d1 |

L |

L1 |

1111·001/1000087 |

10.00 |

10.0 |

6.5 |

133 |

87 |

1075094 |

10.75 |

10.0 |

7.1 |

142 |

94 |

1100094 |

11.00 |

10.0 |

7.1 |

142 |

94 |

1175094 |

11.75 |

10.0 |

7.1 |

142 |

94 |

1200101 |

12.00 |

12.0 |

7.8 |

151 |

101 |

1275101 |

12.75 |

12.0 |

8.1 |

151 |

101 |

1300101 |

13.00 |

12.0 |

8.4 |

151 |

101 |

1375108 |

13.75 |

12.0 |

9.1 |

160 |

108 |

1400108 |

14.00 |

12.0 |

9.1 |

160 |

108 |

1475114 |

14.75 |

12.0 |

9.7 |

169 |

114 |

1500114 |

15.00 |

12.0 |

9.7 |

169 |

114 |

1575120 |

15.75 |

12.0 |

10.4 |

178 |

120 |

1600120 |

16.00 |

16.0 |

10.4 |

178 |

120 |

1675125 |

16.75 |

16.0 |

11.0 |

184 |

125 |

1700125 |

17.00 |

16.0 |

11.0 |

184 |

125 |

1775130 |

17.75 |

16.0 |

11.7 |

191 |

130 |

1800130 |

18.00 |

16.0 |

11.7 |

191 |

130 |

1870135 |

18.70 |

16.0 |

12.3 |

198 |

135 |

1900135 |

19.00 |

16.0 |

12.3 |

198 |

135 |

1970140 |

19.70 |

16.0 |

13.0 |

205 |

140 |

2000140 |

20.00 |

20.0 |

13.0 |

205 |

140 |

- Q: How can the reaming of stainless steel extend the life of the reamer and allow Kong Guangliang to help with various problems?

- Must work card reamer, oil tapping oil, black thick oil

- Q: Mr. Cui, Kong is 9.97. I want to use my 10H7 reamer to reaming the hole with my hand. The book said that small or excessive margin will affect the reaming accuracy, then 0.03 of the margin can also be reaming to hinge it? I don't quite understand why the small margin affects the accuracy of reaming If so, what else would be done with thick hinges and precision hinges?.

- Each knife distribution margin will be not the same, you are asked to assign allowance Oh, recommended by electroplating diamond reamer, you do not know the accuracy is not high, if the demand is high, is recommended by electroplating reamer, it can be divided into coarse and fine reamer to hinge, to consult Henan stone diamond reamer.

- Q: In the lathe, with a floating reamer machining material for cast iron, diameter of 55mm hole, leaving margin 0.1mm, lathe speed is appropriate!!

- 80--120 remember to lubricate

- Q: What are the major brands of reamers I?

- Do you want a hand reamer or a machine reamer? High speed steel or hard alloy material?Is it for NC machining of CNC?

- Q: Would you like to make a straight hole reamer with an outer diameter of 32, an inner hole of 12, and a tolerance of -0--0.02. The inner hole and reamer must be concentric. How can I do that?

- I can only draw. Would you like me to do it for you?

- Q: What's the difference between a bore cutter and a reamer?

- In general, a reamer is fixed size tool, cutter is adjustable size tool.

- Q: Can we use milling cutters instead of reamer to process holes, the accuracy of holes H7

- High precision, precision milling cutter H7 is not so high you can use boring

- Q: Processing materials for aluminum parts, unilateral processing allowance of 0.7 mm, four blade is indeed higher machining accuracy, but the row cutting than the three blade almost

- Since it is reaming, choose three blades. Black holes make sense.

- Q: What is CNC reamer?

- Generally refers to the single indexable blade reamer (currently only international companies only), such as Sweden and Germany is MAPAL indexable single edge reamer, cutting smoothly without vibration, high machining accuracy, reaming allowance, high cutting speed, shape and position error is small, long tool life;But some people put the reamer in the NC machine tool called NC reamer, the scope is big, a reamer, common straight shank machine machine reamers with adjustable pressure, expansion reamer, reamer taper and taper shank reamer etc..

- Q: Hit a circle, beating is 2-3 wire, reaming 16 holes should be little problem. 20-30 spare margins are left, and the reamer is new. But why does this problem arise? Ask the teacher for help!!!

- Your speed is not fast, generally more than 300400 on it. What is your tolerance?There are scratches generally have to squeeze the squeeze, the margin is large, generally 5 silk on it.

1. Manufacturer Overview

| Location | Shaanxi,China |

| Year Established | 2010 |

| Annual Output Value | Below US$1 Million |

| Main Markets | |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | 1% - 10% |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Flute Reamer

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Pieces pc

- Supply Capability:

- 1000 Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches