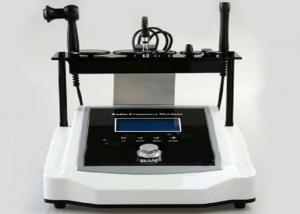

Ultrasonic Plastic Welder

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 200 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ultrasonic Plastic welder

1.quality, stable power output

2.make customized sonotrode

3.easy maintenance

4.adjustable base

Ultrasonic Plastic Welder from our factory

- Suitable for thermoplastics welding

- Can weld plastic + metal

- able to make customized sonotrode / welding mold for customers

Advantages of Ultrasonic Welding:

This technique is fast, efficient, non-contaminating and requires no consumables.

Features:

1.high quality air-drive mechanism & components

2.ceramic coated converter, ensure constant and powerful output

3.titanium alloy booster

4.adjustable base plate

5.Integrated design or Seperate design available

6.easy maintenance

7.Custom made is welcome

8.WE CAN MAKE CUSTOMIZED MOLD BASED ON CUSTOMER NEEDS

Specifications:

Model No. |

HN-1500 |

Ultrasonic Power |

1500W |

Ultrasonic Frequency |

20Khz |

Ultrasonic time |

0.1-5 seconds |

Welding Machine Dimension |

40 * 68 * 110 CM |

Ultrasonic Generator case |

38*54*14 CM |

Steel shelf |

have |

Net weight |

130 kg |

Power supply |

AC100V-120V, AC220V-240V |

We pride ourselves on supplying customers with high quality machines and offering technical knowledge and cleaning solutions. We also manufacture Automatic Welding systems.

Our factory is committed to doing most so that customers can meet business and operational requirements. Let our 18 years of experience work for you.

OTHER MODELS AVAILABLE FOR REFERNCE

Model |

HN-400 |

HN-800 |

HN-1200 |

HN-1500 |

HN-2000 |

Ultrasonic Power |

400W |

800W |

1200W |

1500W |

2000W |

Ultrasonic Frequency |

28/40 Khz |

28/40 Khz |

15/20 Khz |

15/20Khz |

15/20Khz |

Pneumatic Cylinder |

75 mm |

75 mm |

75mm |

75mm |

75mm |

Ultrasonic Time |

0.1-5 seconds |

0.1-5 seconds |

0.1-5 seconds |

0.1-5 seconds |

0.1-5 seconds |

Stay Time |

0.1-5 seconds |

0.1-5 seconds |

0.1-5 seconds |

0.1-5 seconds |

0.1-5 seconds |

Lingerin Time |

0.1-5 seconds |

0.1-5 seconds |

0.1-5 seconds |

0.1-5 seconds |

0.1-5 seconds |

Power supply |

AC100V-120V,

AC220V-240V |

AC100V-120V,

AC220V-240V |

AC100V-120V,

AC220V-240V |

AC100V-120V,

AC220V-240V |

AC100V-120V,

AC220V-240V |

How Ultrasonic Plastic Welders work:

Ultrasonic plastic welders operate by inducing ultrasonic frequencies in plastic components that is converted into heat between the welded plastic laminates. Frictional heat is produced so that thermoplastic parts melt and an insoluble connection between parts is forged in a very short period of time. The melting points of both working pieces is nearly equivalent which helps to form a uniform weld area. The welded area is usually as strong as the matrix material.

- Q: What's the difference between metal welding machine and plastic welding machine?

- The difference is big, general welding metal welding machine is not welding blister, plastic can use high frequency welding machine welding;

- Q: What are their differences? What are the manufacturers of high frequency welding machines?

- Plastic welding machine buy high frequency welding machine? Or ultrasonic plastic welding machine? Is based on their own products, requirements to determine, ultrasonic plastic welding machine is plastic, plastic welding, high-frequency machine is blister, 2 different products

- Q: What kind of factory will use big ultrasonic plastic welding machine?

- Application industry:Plastic welding machine is widely used in the automotive industry, electronics industry, medical industry, household electrical appliance industry, non-woven clothing, office supplies, packaging industry, toy industry, etc..The automotive industry: plastic body parts, car doors, car auto meter, auto lamp, sun visor, interiors, filter, reflective material, reflective spike, bumper, cable, motorcycle plastic filter, radiator, brake fluid tank, oil tank, oil tank, air duct, exhaust purifier, filter plate, tray;Plastic electronics: prepaid water meter, communication equipment, cordless telephone, mobile phone accessories, mobile phone shell, shell, battery charger, valve controlled sealed lead-acid battery maintenance, 3 inch floppy disk, U disk, SD card, CF card, USB connectors, bluetooth;Toys stationery: folders, photo albums, folding box, PP hollow board, pen, ink cartridges, toner cartridges;Medical Daily: watches, kitchenware, oral liquid bottle, bottle cap, mobile phone accessories, some gold soft brush, daily necessities;Health products: Children's products, air mattress, racks, knife, gardening supplies, kitchenware sanitary ware, shower, gold soft brush, shower head, bottle, cosmetic bottle, coffee pot, washing machine, air dehumidifier, electric irons, electric kettle, vacuum cleaner, metal box cover and geogrid etc..

- Q: How can ultrasonic plastic welding machine replace ultrasonic mould?

- First, the ultrasonic transducer horn contact the mold place, with cloth or alcohol wipe clean, followed by ultrasonic, mold a little to tighten!

- Q: What's the difference between ultrasonic plastic welding machine and ultrasonic plastic hot melt machine?

- It's all one thing

- Q: Ultrasonic plastic welding machine die is not durable, what material good?

- Look what you weld. The efficiency is highest. Aluminum alloy 7075.

- Q: Must be able to believe 8700AD ultrasonic plastic welding machine often appear failures and treatment methods?

- I must be your dear brother.

- Q: Please describe in detail the 2015 mould material manufacturing process, pay attention to the problem, the relevant difficult solution

- To do ultrasonic mold of the same product, method of making diversification (material is usually Aluminum Alloy / titanium alloy / steel is also useful; and as the shape but round / square / combination and so on, are different), I can't say this two can let everyone know (because the design of ultrasonic mold needs the knowledge, such as: material mechanics / acoustic / wave, etc.) but must have the ultrasonic testing equipment to ensure the quality of ultrasonic mold.

- Q: Ultrasonic plastic welding machine power, the better the better?

- Of course not, the greater the power the better, but according to the size of the plastic products to determine the size of the welding surface, the need for power

- Q: Which brand is the best for ultrasonic plastic welding machine?

- Imports are better than domestic, domestic too much, almost the same. Now the ultrasonic plastic welding machine is not stable

1. Manufacturer Overview

| Location | Guangdong, China (Mainland) |

| Year Established | 1993 |

| Annual Output Value | US$50 Million - US$100 Million |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe Central America Northern Europe Southern Europe |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | 1-2 People |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 3,000-5,000 square meters |

| No. of Production Lines | 6 |

| Contract Manufacturing | OEM Service Offered Design Service Offered |

| Product Price Range | High and/or Average |

Send your message to us

Ultrasonic Plastic Welder

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 200 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords