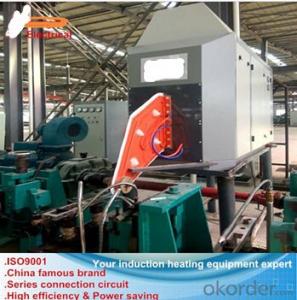

H-beam Welding Equipment ( 300kW or 600kW )

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Application Scope

H-beam welding, contact welding of plate in-line

Function Structure

Light H-beam has been widely applied as building material and has a very good market prospect. High frequency H-beam welding is a new technology for H-beam welding with the advantages of energy-saving, high efficiency and convenient operation etc.

H-beam welding equipment adopts two sets 300kW or 600kW solid state high frequency welder with exactly the same model. One welds web plate and upper flange plate, the other welds web plate and lower flange plate. The welding mode is contact welding. Solid state high frequency welder adopts AC-DC-AC frequency conversion structure. The rectifier adopts 3-phase thyristor. The inverter adopts high voltage large power MOSFET to form full bridge resonance inversion. Inverter output adopts high efficiency ferrite matching transformer to finish power combination, impedance matching and electrical isolation. Resonance tank circuit adopts two sides serial resonance.

The complete unit of equipment is composed of switchgear rectifying cabinet, inverter output cabinet, contact head mechanism, circulation soft water cooling system, console and 3-D positioning table.

Technical Features

Ø Perfect structure design

1.Independent design of switchgear rectifying cabinet and inverter output cabinet, connected by soft cable, which is convenient for layout at user’s site.

2.Power combination of the inverter bridge is accomplished by the way of power unit superposition. Each MOSFET power unit is designed to be 100kW and slideway drawer structure, which is convenient for installation and repair.

3.3-D positioning table is adopted for both of the two sets contact type welder. Contact head adopts pressure control, which has a good synchronism and consistency.

4.High standard electromagnetism compatibility design, electromagnetism radiation meets national standard.

5.Closed cabinet design, meeting rigor environmental requirements on site.

Ø Full-digital Synchronization Control System

1. 3-phase rectifier adopts high cost performance MCU controlling to realize precise synchronism trigger with high control precision and small grid-side non characteristic harmonic.

2. Resonant inverter adopts CPLD to form full-digital control system that is characterized by their automatic constant angle, high phase-lock precise and wide scope of phase-lock.

3. The two sets solid state high frequency welder has the function of synchronization control with the features of stable working and small interference.

4.The welder has perfect protection function with reliable working and low failure rate.

Ø HMI and fault diagnosis system

1. Adopt PLC and touch screen to form perfect HMI system.

2. Realize integrated automatic control of welder system.

3. Fault display and diagnosis system.

Main Technical Parameter

Welder model | AC input | Rated DC voltage | Rated DC current | Frequency Scope | Electrical efficiency | Welding method Working status |

GGP300-0.3H | 3AC380V 50/60Hz | 450V | 660A | 250~ 300 kHz | ≥85% | Contact welding continuous |

GGP600-0.3H | 3AC380V 50/60Hz | 450V | 1300A | 250~ 300 kHz | ≥85% | Contact welding continuous |

- Q: What is the influence of the cooling rate after welding on the mechanical properties of the weld?

- For second types of steels which are sensitive to temper embrittlement, slow cooling can lead to slow cooling embrittlement.

Send your message to us

H-beam Welding Equipment ( 300kW or 600kW )

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords