Stainless Steel Wire Mesh Panel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

| Place of Origin: | Material: | Type: | |||

| Application: | Weave Style: | Wire Diameter: | |||

| Technique: | Model Number: | Brand Name: | |||

| product name(stainless steel mesh): | stainless steel wire mesh usage: | stainless steel mesh other using: | |||

| stainless steel net characteristic: | stainless steel net other characteristic: | Stainless steel mesh deep processing: | |||

| Stainless steel net Further processing: | Stainless steel wire mesh weave: | Stainless steel wire mesh: | |||

| Stainless steel wire mesh wire diameter: |

Packaging & Delivery

| Packaging Detail: | packing:waterproof paper inside, plastic film outside, then pallet or wooden box. Stainless Steel Wire Cloth |

| Delivery Detail: | 10-15 day Stainless Steel Wire Cloth |

Specifications

Stainless Steel Wire Cloth

stainless steel mesh use very broad

wire mesh/filte net/wire cloth

Texture/SS304,316,430,201,320

- Q: Can steel wire mesh be used for safety barriers?

- Yes, steel wire mesh can be used for safety barriers. Steel wire mesh is a durable and sturdy material that can effectively provide protection and enhance safety in various applications such as construction sites, highways, and industrial areas. It can be easily installed and offers visibility while preventing unauthorized access or potential hazards.

- Q: What are the different shapes of steel wire mesh available?

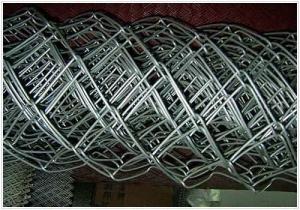

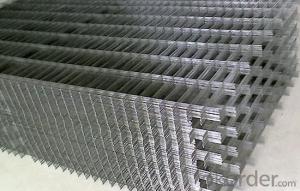

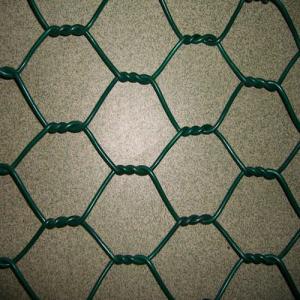

- A variety of steel wire mesh shapes are available, each serving distinct purposes based on their structural design and application. Some commonly used shapes include: 1. Square Mesh: The most basic shape of steel wire mesh, consisting of evenly spaced wires running perpendicular to each other, forming square openings. Square mesh is versatile and widely utilized in industries such as construction, agriculture, and fencing. 2. Rectangular Mesh: Similar to square mesh, but with rectangular openings instead of square ones. This shape offers greater flexibility in terms of wire spacing and is often preferred for specific applications, such as architectural and decorative purposes. 3. Hexagonal Mesh: Also known as chicken wire or poultry netting, this mesh is characterized by its hexagonal-shaped openings. It finds common use in the agricultural and industrial sectors, primarily for fencing, animal enclosures, and erosion control. 4. Diamond Mesh: Featuring diamond-shaped openings, this mesh offers superior strength and stability. It is suitable for applications requiring higher tensile strength, such as security fencing, gabion walls, and reinforcement in concrete structures. 5. Welded Mesh: Created by welding intersecting wires at their junctions, forming a grid-like pattern. This mesh is available in various shapes, including square, rectangular, and diamond. It is highly durable and frequently used in construction, industrial, and agricultural applications. 6. Expanded Metal Mesh: Produced by cutting and stretching a flat sheet of metal, creating a pattern of diamond-shaped openings. This shape provides an excellent strength-to-weight ratio, efficient airflow, and visibility, making it suitable for applications like walkways, safety barriers, ventilation grilles, and filters. 7. Twilled Weave Mesh: Consisting of wires woven together in a twill pattern, creating diagonal lines or ridges across the surface. This shape offers increased strength and durability, making it ideal for heavy-duty applications such as sieves, filters, and conveyor belts. These examples illustrate the various shapes of steel wire mesh available. The choice of shape depends on specific application requirements, including strength, flexibility, aesthetics, and airflow.

- Q: Can steel wire mesh be used for hanging artwork?

- Yes, steel wire mesh can be used for hanging artwork. It is a strong and durable material that can support the weight of artwork effectively. Additionally, its open design allows for easy attachment and adjustment of artwork using hooks or clips.

- Q: Can steel wire mesh be used for construction purposes?

- Certainly, construction purposes can definitely make use of steel wire mesh. This adaptable material offers numerous benefits in construction projects. Reinforcing concrete structures like slabs, columns, and beams is a common application of steel wire mesh. It imparts additional strength and stability to the concrete, thereby making it more resistant to cracks and structural failures. Moreover, steel wire mesh serves as an excellent fencing material for construction sites, ensuring security and preventing unauthorized access. It is also frequently employed for creating barriers and enclosures in construction projects, such as retaining walls, partitions, and cages. Another significant utilization of steel wire mesh in construction is in the form of gabions. These wire mesh containers, filled with stones or other materials, are used to construct retaining walls, erosion control structures, and noise barriers. Steel wire mesh imparts the necessary strength and durability to withstand the forces exerted by such structures. Additionally, architectural applications can benefit from the use of steel wire mesh, particularly in facades and decorative elements. Its malleability allows for the creation of creative designs and patterns, thereby enhancing the aesthetic appeal of the construction. Overall, steel wire mesh is a dependable and versatile material that can effectively serve various construction purposes. It contributes to the structural integrity, security, and visual appeal of the project.

- Q: Can steel wire mesh be used for privacy fencing?

- Yes, steel wire mesh can be used for privacy fencing. While it may not provide as much privacy as solid fences, steel wire mesh with smaller openings can still offer a level of privacy by obstructing the view and preventing direct line of sight. Additionally, the mesh can be combined with other materials such as vinyl or wood to enhance privacy. It is important to ensure that the mesh is of a suitable thickness and height, and that it is properly installed to create a secure and effective privacy fence.

- Q: What are the benefits of using steel wire mesh in the chemical industry?

- Steel wire mesh offers several benefits in the chemical industry. Firstly, it provides excellent strength and durability, making it ideal for applications that require resistance to corrosion, heat, and chemicals. Secondly, its open structure allows for efficient filtration and separation processes, ensuring the purity of chemicals and preventing contamination. Additionally, steel wire mesh is easily customizable, allowing for the creation of specific mesh sizes and shapes to meet industry requirements. Its versatility also enables its use in various chemical processes, such as catalyst support, reactor internals, and gas diffusion. Overall, steel wire mesh enhances safety, efficiency, and reliability in the chemical industry.

- Q: Is steel wire mesh suitable for use in medical devices?

- Steel wire mesh is not typically suitable for use in medical devices. Medical devices require materials that are biocompatible, meaning they do not have any toxic or harmful effects on the human body. Steel wire mesh, on the other hand, can potentially cause issues such as allergic reactions or infections when in contact with body tissues or fluids. Additionally, steel wire mesh is not easily sterilizable, which is a critical requirement for medical devices to prevent the spread of infections. Therefore, alternative materials such as titanium or medical-grade plastics are commonly used in medical devices due to their biocompatibility and ease of sterilization.

- Q: How is steel wire mesh used in reinforcement of high-rise buildings?

- Steel wire mesh is commonly used in the reinforcement of high-rise buildings as it provides structural support and increases the overall strength and stability of the building. The wire mesh is typically placed in concrete structures, such as walls, columns, and slabs, during the construction process. One of the main functions of steel wire mesh is to distribute the load evenly across the concrete structure, thereby reducing the risk of cracks and other structural failures. The mesh acts as a reinforcement, helping to resist the tensile forces that can occur in high-rise buildings due to factors like wind, seismic activity, and the weight of the structure itself. In addition to its load-bearing capabilities, steel wire mesh also enhances the durability and longevity of the building. By preventing the formation and propagation of cracks, the mesh helps protect the concrete from moisture penetration, corrosion, and other damaging elements. This is especially crucial in high-rise buildings, where the exposure to external forces and environmental conditions is higher. Moreover, steel wire mesh is easy to handle and install, making it a cost-effective solution for reinforcing high-rise buildings. The mesh is typically manufactured in large rolls or sheets, which can be easily cut and shaped to fit the required dimensions. This allows for a quick and efficient installation process, saving both time and labor costs during construction. Overall, steel wire mesh plays a crucial role in the reinforcement of high-rise buildings by providing structural support, distributing loads, preventing cracks, and enhancing durability. Its use in construction ensures the safety and longevity of these tall structures, making them more resistant to various forces and increasing their overall structural integrity.

- Q: Can steel wire mesh be used for insect control?

- Yes, steel wire mesh can be used for insect control. Steel wire mesh is known for its durability and strength, making it an effective barrier against insects. It can be installed on windows, doors, vents, or any other openings to prevent insects from entering a space. The fine openings in the mesh allow for air circulation while keeping out mosquitoes, flies, bees, and other pests. Additionally, steel wire mesh is resistant to corrosion and weathering, ensuring a long-lasting solution for insect control.

- Q: What are the different weaving patterns available in steel wire mesh?

- Some of the different weaving patterns available in steel wire mesh include plain weave, twill weave, Dutch weave, and reverse Dutch weave.

Send your message to us

Stainless Steel Wire Mesh Panel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords