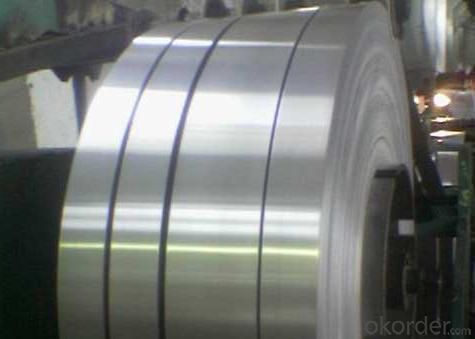

Good Quality Stainless Steel Strips 316L

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 2000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Good Quality Stainless Steel Strips 316L

1. Chemical Composition of Good Quality Stainless Steel Strips 316L

C | Si | Mn | P | S | Ni | Cr |

Max0.03 | max1.00 | max2.00 | max0.045 | max0.03 | 10.00-14.00 | 16.00-18.00 |

2. Mechanical Properties of Good Quality Stainless Steel Strips 316L

Yield Strength | Tensile | Elongation | Hardness (HV) | Hardness (HRB) |

≥175 | ≥480 | ≥40 | ≤200 | ≤90 |

3. Standard of Good Quality Stainless Steel Strips 316L:

AISI, ASTM, GB, EN, DIN, JIS

4. Surface of Good Quality Stainless Steel Strips 316L

2B, NO.1, BA, NO.4, Hairline, SB, Mirror finish, Anti-skid, Cherkered etc.

5. Size of Good Quality Stainless Steel Strips 316L

Thickness: 0.3-3mm (cold rolled), 3-40mm (hot rolled)

Width: 1000mm or 1219mm or 1240mm for cold rolled, 1500mm for hot rolled.

Length: As customers' request.

6. MOQ of Good Quality Stainless Steel Strips 316L

1 Ton

7. Payment Terms of Good Quality Stainless Steel Strips 316L

T/T or L/C

8. Packing of Good Quality Stainless Steel Strips 316L

Seaworthy package with wooden or Iron pallets with the paper and the steel strip, or as customers' request.

9. Delivery Time of Good Quality Stainless Steel Strips 316L:

Usually about 7 days after we confirming the order, or according to your quantity.

If you have any question or demand, pls feel free to contact me.

- Q: What is the maximum length of stainless steel wire that can be supplied?

- The maximum length of stainless steel wire that can be supplied depends on various factors, including the manufacturing capabilities and resources of the supplier. However, stainless steel wire is often available in long continuous lengths. In general, stainless steel wire can be supplied in lengths ranging from a few feet to thousands of feet. Some suppliers may even be able to provide custom lengths based on specific requirements. It is best to consult with the supplier or manufacturer directly to determine the maximum length of stainless steel wire they can supply.

- Q: Is stainless steel wire flexible or rigid?

- Stainless steel wire is flexible.

- Q: How is stainless steel wire rope constructed?

- Multiple strands of stainless steel wires are intertwined to construct stainless steel wire rope. Typically, there are three main components involved in the construction: wires, strands, and the core. The wires used in stainless steel wire rope are usually made of corrosion-resistant stainless steel alloy. These wires are thin and flexible, making it easy to weave them together. The quantity of wires used can vary, depending on the desired strength and flexibility of the final product. Next, the wires are twisted together to create strands. The number of wires in each strand can also vary based on specific application requirements. This twisting process adds strength and stability to the wire rope. Lastly, the strands are twisted around a core to form the final stainless steel wire rope. The core can be made of different materials like fiber or steel, providing additional strength and support to the wire rope. In summary, the construction of stainless steel wire rope involves the meticulous intertwining of multiple strands of stainless steel wires. The end result is a strong and durable product that is resistant to corrosion, suitable for a wide range of applications.

- Q: What are the different types of stainless steel wire brushes?

- There are several different types of stainless steel wire brushes available, each designed for specific applications and purposes. Some of the most common types include: 1. Crimped wire brushes: These brushes have a crimped wire pattern, which helps to increase the flexibility and surface coverage. They are commonly used for light to medium-duty cleaning and deburring tasks. 2. Knotted wire brushes: These brushes have wire knots that are twisted together, providing a more aggressive brushing action. They are ideal for heavy-duty tasks such as removing rust, weld scale, and corrosion from metal surfaces. 3. Cup brushes: Cup brushes have a cylindrical shape with bristles arranged in a cup-like configuration. They are typically used for cleaning large flat surfaces, such as removing paint or rust from metal parts. 4. Wheel brushes: Wheel brushes are similar to cup brushes but have a wheel-shaped design. They are often used for cleaning and finishing applications on curved or irregular surfaces. 5. End brushes: End brushes have bristles arranged in a circular pattern at the end of the brush. They are commonly used for reaching tight or hard-to-reach areas, such as cleaning threads, grooves, or crevices. 6. Miniature brushes: These brushes are small in size and are often used for precision cleaning or detailing work. They are commonly used in industries like jewelry making, electronics, or dental applications. 7. Strip brushes: Strip brushes consist of a strip of stainless steel wire bristles held together by a metal or plastic backing. They are frequently used for industrial applications, such as sealing gaps, dust or debris removal, or conveyor belt cleaning. Each type of stainless steel wire brush has its own unique characteristics and applications, so it's important to choose the right brush for the specific task at hand.

- Q: Can stainless steel wire be used for hanging lights or fixtures?

- Yes, stainless steel wire can be used for hanging lights or fixtures. Stainless steel is a durable and corrosion-resistant material, making it suitable for supporting the weight of lights or fixtures without compromising their stability or safety.

- Q: Can stainless steel wire be used for piano wire?

- Yes, stainless steel wire can be used for piano wire. While traditional piano wire is typically made of high carbon steel, stainless steel wire can also be used as a suitable alternative. Stainless steel wire offers corrosion resistance and durability, making it a viable option for piano wire applications. However, it is important to consider the specific requirements and characteristics of the piano in question before deciding on the type of wire to be used.

- Q: Can stainless steel wire be used for springs in the jewelry industry?

- Yes, stainless steel wire can be used for springs in the jewelry industry. Stainless steel is a popular choice for jewelry making due to its durability, corrosion resistance, and aesthetic appeal. It is commonly used for various components, including springs, clasps, and findings. Stainless steel springs provide strength and flexibility, making them suitable for different types of jewelry, such as bracelets, necklaces, and earrings. Additionally, stainless steel wire can be easily shaped and manipulated to create intricate designs, making it a versatile material for jewelry springs.

- Q: Is stainless steel wire suitable for wire rope connectors?

- Yes, stainless steel wire is suitable for wire rope connectors. Stainless steel is known for its high strength, durability, and resistance to corrosion, making it an excellent choice for wire rope connectors that require reliability and longevity in various applications.

- Q: Can stainless steel wire be used for knitting needles?

- Yes, stainless steel wire can be used for knitting needles. Stainless steel is a durable and strong material that is resistant to rust and corrosion, making it an excellent choice for knitting needles. It provides a smooth surface that allows stitches to glide easily, resulting in a more enjoyable and efficient knitting experience. Additionally, stainless steel needles are less likely to break or bend compared to other materials, ensuring their longevity. However, it is important to note that stainless steel needles may feel colder to the touch than other materials, which could be a factor to consider depending on personal preference.

- Q: Is stainless steel wire suitable for wire winding?

- Indeed, wire winding is a suitable application for stainless steel wire. Renowned for its robustness, longevity, and ability to withstand corrosion, stainless steel wire is widely favored in numerous fields, including wire winding. Its remarkable flexibility enables effortless shaping and coiling into tight spirals or spools without compromising its structural soundness. Moreover, stainless steel wire comes in various grades and thicknesses, facilitating customization to meet specific wire winding needs. Consequently, stainless steel wire emerges as an unwavering and adaptable choice for wire winding endeavors.

Send your message to us

Good Quality Stainless Steel Strips 316L

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 2000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords