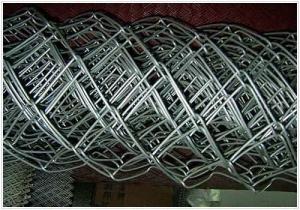

Stainless Steel Decoration Chain link Fence for Garden

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 20000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description Stainless Steel Decoration Chain link Fence for Garden:

The perforate metal wind and dustproof wall can keep the clean cenvironment and save the coal for you.nd and dust screen, wind and dust barrier, windproof and dustproof wall, dust suppressiondproof wall

Specification of Stainless Steel Decoration Chain link Fence for Garden

Material: steel plate, galvanized plate, color coated sheet, stainless steel sheet.

Surface treatment: electrostatic powder coating.

Color: red ,blue or as customers' request.

Hole type: round, length, square, scale hole, hexagonal hole, plum blossom and so on.

Anti wind net application Stainless Steel Decoration Chain link Fence for Garden:

1. Power plants, coal mines, coking plants, coal washing plant, and other businesses field for coal saving

2. Ports, wharf and other coal storage yard

3. Open-air storage yard of the steel company, building materials company, cement companies, etc

4. All kinds of coal storage field

5. Temporary dustproof and windproof wall for the building site.

features of Stainless Steel Decoration Chain link Fence for Garden:

1. Can be readily formed

2. Easy installation

3. Can be painted or polished and anodizing

4. The thickness of materials is wide range from 0.3mm-8mm

5. Largest selection of hole size patterns and configurations

6. Uniform sound abatement

7. Attractive appearance

FAQ

1. Payment term: T/T, L/C, Western Union

2. Payment terms: 30% by T/T should be paid in advance, the balance payment paid againest the copy of B/L

3. Delivery time: shipping products within ten days, or negotiate according to total quantity.

4. Min order quantity: 50 pieces, or by negotiate with each other

- Q: Can steel wire mesh be used for mining applications?

- Yes, steel wire mesh can be used for mining applications. It is commonly used in mining operations for purposes such as reinforcing tunnel walls, supporting roofs, and preventing loose rocks from falling. Steel wire mesh provides durability, strength, and flexibility, making it suitable for various mining tasks and ensuring worker safety.

- Q: Can steel wire mesh be coated with PVC?

- Yes, steel wire mesh can be coated with PVC. PVC coating provides several benefits to the steel wire mesh. It adds a layer of protection against corrosion, making the mesh more durable and long-lasting. The PVC coating also enhances the appearance of the mesh, giving it a smooth and attractive finish. Additionally, the PVC coating can provide insulation properties, making the mesh suitable for various applications, including fencing, construction, and industrial uses.

- Q: Is steel wire mesh suitable for use in mining or quarrying operations?

- Without a doubt, steel wire mesh proves to be a fitting option for utilization in mining and quarrying endeavors. Renowned for its robustness, endurance, and ability to withstand deterioration, this material is perfectly suited for the demanding conditions and heavy loads associated with mining and quarrying activities. In the realm of mining and quarrying, steel wire mesh is widely employed for diverse purposes. It serves as a reliable support structure for walls, roofs, and tunnels, ensuring stability and reinforcement. Additionally, it acts as a safety precaution, effectively preventing the occurrence of accidents caused by loose rocks or debris falling. Furthermore, steel wire mesh finds utility as a screening material in mining and quarrying undertakings. It facilitates the segregation of rocks, minerals, or other substances of varying sizes, thereby enabling efficient processing and sorting. The mesh's open design facilitates the unhindered passage of water, air, and fluids, a crucial factor in numerous mining and quarrying processes. Moreover, steel wire mesh exhibits remarkable resistance to extreme temperatures, chemicals, and corrosive surroundings, rendering it suitable for deployment across a broad spectrum of mining and quarrying operations. Its immunity to rust and corrosion ensures durability, even amidst challenging conditions. In conclusion, it is evident that steel wire mesh is exceedingly well-suited for mining and quarrying endeavors. Its strength, durability, resistance to wear and tear, and versatility render it an exceptional choice for multifarious applications within these industries.

- Q: Is steel wire mesh suitable for retaining walls?

- Yes, steel wire mesh is suitable for retaining walls. It provides structural stability, reinforcement, and prevents soil erosion, making it a reliable choice for retaining walls.

- Q: Can steel wire mesh be used for waste water treatment?

- Yes, steel wire mesh can be used for waste water treatment. Steel wire mesh is often used as a filter medium in various water treatment processes, including waste water treatment. It is commonly employed in applications such as screening out large debris or particles from the waste water, preventing them from entering the treatment system. The steel wire mesh acts as a barrier, allowing water to pass through while capturing solid waste. Additionally, steel wire mesh can also be used as a support structure for other filtration media, such as activated carbon or sand, enhancing the overall treatment efficiency. Overall, steel wire mesh is a versatile and durable material that can effectively contribute to waste water treatment processes.

- Q: Is steel wire mesh fire-resistant?

- Yes, steel wire mesh is fire-resistant.

- Q: What are the different strength classifications for steel wire mesh?

- The different strength classifications for steel wire mesh are typically based on the diameter of the wire used, which can range from lightweight to heavy-duty. The strength classifications may also consider the spacing between the wires, as well as the type of weave or pattern used in the mesh.

- Q: What are the different tensioning options for steel wire mesh?

- There are several tensioning options available for steel wire mesh, depending on the specific application and desired level of tension. Some common tensioning methods include: 1. Hand tensioning: This method involves manually stretching the wire mesh by hand and securing it to a frame or structure. It is a simple and cost-effective option for small-scale installations or temporary projects. 2. Mechanical tensioning: Mechanical tensioning utilizes mechanical devices such as tension bars, turnbuckles, or ratchets to apply and maintain tension in the wire mesh. This method allows for precise tension control and can be used for both small and large-scale installations. 3. Hydraulic tensioning: Hydraulic tensioning involves the use of hydraulic cylinders or jacks to apply tension to the wire mesh. This method is commonly used for large-scale installations where high tension levels are required. It offers excellent control and is suitable for long-term or permanent installations. 4. Pneumatic tensioning: Pneumatic tensioning utilizes compressed air or gas to apply tension to the wire mesh. It is a quick and efficient method, suitable for both small and large-scale installations. Pneumatic tensioning devices can be easily adjusted to achieve the desired tension level. 5. Electric tensioning: Electric tensioning involves the use of electric motors or actuators to apply and maintain tension in the wire mesh. This method offers precise tension control and is commonly used in automated or electronically controlled systems. Each tensioning option has its advantages and disadvantages, and the choice depends on factors such as the scale of the project, the required tension level, and the available resources. It is important to consider the specific requirements and consult with experts to determine the most suitable tensioning method for a given steel wire mesh application.

- Q: How is steel wire mesh used in reinforcement of walls?

- Steel wire mesh is commonly used in the reinforcement of walls to provide increased strength and stability. It is typically embedded within the concrete or mortar during construction to enhance the overall structural integrity of the wall. The wire mesh acts as a reinforcement by distributing the load and preventing cracks or fractures from forming. It also helps to control the expansion and contraction of the wall, ensuring its durability over time.

- Q: Can steel wire mesh be used for greenhouse structures?

- Yes, steel wire mesh can be used for greenhouse structures. Steel wire mesh is a versatile material that can be used in various applications, including greenhouse structures. It is strong, durable, and can withstand harsh weather conditions, making it suitable for constructing a greenhouse. The wire mesh provides structural support and allows for ample airflow and sunlight penetration, essential for plant growth. Additionally, steel wire mesh is resistant to rust and corrosion, ensuring the longevity of the greenhouse structure. Overall, steel wire mesh is a reliable choice for greenhouse construction due to its strength, durability, and ability to create a conducive environment for plant cultivation.

Send your message to us

Stainless Steel Decoration Chain link Fence for Garden

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 20000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords