Stainless Steel Filter Wire Mesh

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

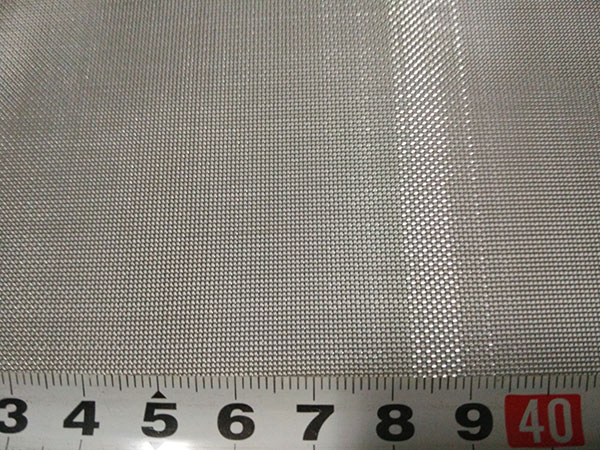

40 Mesh Stainless Steel Wire Mesh

Material: 304 stainless steel wire

Wire Diameter: 0.15 mm

Mesh: 40 mesh

Width: 1m

Length: 30 m/Roll

Popular Specifications Of Stainless Steel Wire Mesh

| stainless steel wire specification(Plain weave) | |||

| mesh | wire dia(mm) | Opening(mm) | Material(Alsl) |

| 7 | 1 | 2.63 | 304 or 316 |

| 10 | 0.6 | 0.94 | 304 or 316 |

| 12 | 0.5 | 1.62 | 304 or 316 |

| 16 | 0.4 | 1.09 | 304 or 316 |

| 16 | 0.35 | 1.24 | 304 or 316 |

| 18 | 0.35 | 1.06 | 304 or 316 |

| 20 | 0.4 | 0.87 | 304 or 316 |

| 24 | 0.26 | 0.8 | 304 or 316 |

| 30 | 0.3 | 0.55 | 304 or 316 |

| 35 | 0.17 | 0.56 | 304 or 316 |

| 40 | 0.23 | 0.4 | 304 or 316 |

| 50 | 0.2 | 0.31 | 304 or 316 |

| 60 | 0.15 | 0.27 | 304 or 316 |

| 70 | 0.12 | 0.24 | 304 or 316 |

- Q: How does the thickness affect the strength of steel wire mesh?

- The thickness of steel wire mesh directly affects its strength. As the thickness of the wire increases, the strength of the mesh also increases. This is because thicker wires have a higher resistance to deformation and are less likely to break or bend under pressure. The additional thickness provides greater structural integrity and makes the mesh more resistant to impact or external forces. Therefore, thicker steel wire mesh is generally more durable and capable of withstanding heavier loads or stresses. Conversely, thinner wire mesh is more susceptible to damage or failure as it has less material to resist deformation.

- Q: What are the different strength options available for steel wire mesh?

- The strength options available for steel wire mesh vary depending on the specific requirements and applications. Common strength options include light-duty, medium-duty, and heavy-duty variants. Light-duty wire mesh typically has lower tensile strength and is suitable for applications that require minimal strength and support. Medium-duty wire mesh offers a balanced combination of strength and flexibility, making it suitable for a wide range of applications. Heavy-duty wire mesh has higher tensile strength and is designed for applications requiring maximum strength and durability, such as construction and industrial applications. Additionally, wire mesh can also be customized to meet specific strength requirements by using different wire gauges and mesh sizes.

- Q: Can steel wire mesh be used for bird or pest control?

- Yes, steel wire mesh can be effectively used for bird or pest control. Steel wire mesh is strong and durable, making it suitable for creating physical barriers that prevent birds or pests from entering certain areas. It can be used to cover openings such as windows, vents, or chimneys, preventing birds or pests from gaining access to buildings or structures. Steel wire mesh can also be used to construct fencing or enclosures to keep birds or pests out of gardens, crops, or other areas where they may cause damage. Additionally, steel wire mesh can be used to create bird netting, which is commonly used in agricultural fields or orchards to protect crops from bird damage. Overall, steel wire mesh is a versatile and effective solution for bird or pest control.

- Q: Wall horizontal seam hanging wire mesh insulation nail spacing is generally how much

- Insulation equipment and containers, should be used to maintain the insulation nip insulation layer, the spacing is generally 200mm. When the need to use welding hook nail fixed insulation layer, the spacing is generally 250mm.

- Q: Is steel wire mesh suitable for agricultural use?

- Yes, steel wire mesh is suitable for agricultural use. It is often used in fencing, enclosures, and animal containment to provide secure and durable protection for crops, livestock, and property. The strength and durability of steel wire mesh make it effective in keeping out pests and predators while allowing for adequate airflow and visibility. Additionally, it is resistant to weather conditions, ensuring its longevity in agricultural settings.

- Q: What are the benefits of using steel wire mesh in the aerospace industry?

- There are several benefits of using steel wire mesh in the aerospace industry. Firstly, steel wire mesh provides excellent strength and durability, making it suitable for applications that require high load-bearing capacities and resistance to extreme conditions. Secondly, its lightweight nature helps reduce the overall weight of aircraft, enabling better fuel efficiency and lower operational costs. Additionally, steel wire mesh offers excellent corrosion resistance, which is crucial for maintaining the structural integrity of aircraft components in harsh environments. Lastly, its versatility allows for various applications, such as reinforcing composite materials, creating protective barriers, and facilitating airflow management, making it a valuable material for enhancing safety and performance in aerospace engineering.

- Q: What are the different weave patterns available for steel wire mesh?

- Some common weave patterns available for steel wire mesh include plain weave, twill weave, Dutch weave, and reverse Dutch weave. Other variations and combinations of these patterns may also be available depending on the specific requirements and applications.

- Q: How is steel wire mesh used in reinforcement of bridges and viaducts?

- Steel wire mesh is used in the reinforcement of bridges and viaducts by providing additional strength and stability to the concrete structures. The mesh is placed within the concrete during construction, acting as a reinforcement framework that helps distribute loads and prevent cracking or structural failure. By reinforcing the concrete, steel wire mesh increases the overall strength and durability of the bridge or viaduct, ensuring its ability to withstand heavy traffic and environmental forces.

- Q: Can steel wire mesh be used for automotive grilles?

- Yes, steel wire mesh can be used for automotive grilles. It is a durable and robust material that can provide protection to the vehicle's front end while allowing proper airflow. Additionally, steel wire mesh can enhance the aesthetics of the grille, giving the vehicle a stylish and modern look.

- Q: What are the load-bearing capabilities of steel wire mesh?

- The load-bearing capabilities of steel wire mesh depend on various factors such as the thickness of the wire, the size and spacing of the openings, and the overall design and installation of the mesh. However, in general, steel wire mesh is known for its high strength and durability, making it capable of supporting heavy loads. It is commonly used in construction, mining, and industrial applications where it can withstand significant forces and provide structural stability.

Send your message to us

Stainless Steel Filter Wire Mesh

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords