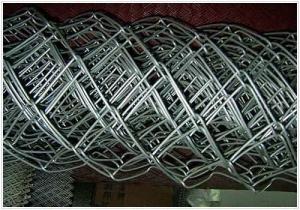

High Quality Stainless Steel Wire Panel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

| Place of Origin: | Material: | Type: | |||

| Application: | Weave Style: | Wire Diameter: | |||

| Technique: | Model Number: | : |

Packaging & Delivery

| Packaging Detail: | waterproof paper |

| Delivery Detail: | depend on amount |

Specifications

304 stainless steel wire mesh

material:s.s304,316,316L,304L,904L

weave type: plain/twill/plain dutch/twill dutch

| Stainless Steel Wire Mesh and Wire Cloth, Plain Weave stainless wire mesh | |||

| Mesh | Wire Dia. (MM) | Opening (MM) | Material (AISI) |

| 7meshx7mesh | 1.00 | 2.63 | 304 or316 |

| 10meshx10mesh | 0.60 | 1.94 | 304 or316 |

| 12meshx12mesh | 0.50 | 1.62 | 304 or316 |

| 16meshx16mesh | 0.40 | 1.19 | 304 or316 |

| 16meshx16mesh | 0.35 | 1.24 | 304 or316 |

| 18meshx18mesh | 0.35 | 1.06 | 304 or316 |

| 20meshx20mesh | 0.40 | 0.87 | 304 or316 |

| 24meshx24mesh | 0.26 | 0.80 | 304 or316 |

| 30meshx30mesh | 0.30 | 0.55 | 304 or316 |

| 35meshx35mesh | 0.17 | 0.56 | 304 or316 |

| 40meshx40mesh | 0.23 | 0.40 | 304 or316 |

| 50meshx50mesh | 0.20 | 0.31 | 304 or316 |

| 60meshx60mesh | 0.15 | 0.27 | 304 or316 |

| 70meshx70mesh | 0.12 | 0.24 | 304 or316 |

| 80meshx80mesh | 0.13 | 0.19 | 304 or316 |

| 90meshx90mesh | 0.12 | 0.16 | 304 or316 |

| 100meshx100mesh | 0.10 | 0.15 | 304 or316 |

| 120meshx120mesh | 0.09 | 0.12 | 304 or316 |

| 150meshx150mesh | 0.063 | 0.11 | 304 or316 |

| 180meshx180mesh | 0.053 | 0.09 | 304 or316 |

| 200meshx200mesh | 0.053 | 0.07 | 304 or316 |

| Stainless Steel Wire Mesh and Wire Cloth, Twill Weave | |||

| 250meshx250mesh | 0.040 | 0.063 | 316 |

| 300meshx300mesh | 0.040 | 0.044 | 316 |

| 325meshx325mesh | 0.035 | 0.043 | 316L |

| 350meshx350mesh | 0.030 | 0.042 | 316L |

| 400meshx400mesh | 0.030 | 0.033 | 316L |

| 450meshx450mesh | 0.028 | 0.028 | 316L |

| 500meshx500mesh | 0.025 | 0.026 | 316L |

| Stainless Steel Wire Cloth, Dutch Weave | ||

| Mesh | Wire Dia. (MM) | Material (AISI) |

| 12mesh x 64mesh | 0.58 x 0.40 | 304 or 316 |

| 24mesh x 110mesh | 0.36 x 0.25 | 304 or 316 |

| 14mesh x 88mesh | 0.50 x 0.33 | 304 or 316 |

| 30mesh x 150mesh | 0.23 x 0.18 | 304 or 316 |

| 40mesh x 200mesh | 0.18 x 0.13 | 304 or 316 |

| 50mesh x 250mesh | 0.14 x 0.11 | 304 or 316 |

| 80mesh x 700mesh | 0.10 x 0.08 | 304 or 316 |

| 165mesh x 800mesh | 0.071 x 0.040 | 304 or 316 |

| 165mesh x 1400mesh | 0.06 x 0.04 | 304 or 316 |

| 200mesh x 1800mesh | 0.05 x 0.032 | 304 or 316 |

| 825mesh x 2300mesh | 0.035 x 0.025 | 316L |

| 400mesh x 2800mesh | 0.030 x 0.02 | 316L |

- Q: Can steel wire mesh be used for architectural purposes?

- Yes, steel wire mesh can be used for architectural purposes. It offers various advantages such as strength, durability, and flexibility in design. Steel wire mesh can be used for façade cladding, partitions, ceilings, and other architectural elements, providing both aesthetic appeal and functional benefits.

- Q: Is steel wire mesh suitable for landscaping?

- Yes, steel wire mesh is suitable for landscaping. It is commonly used for various landscaping applications such as creating fences, trellises, and retaining walls. The durable and strong nature of steel wire mesh ensures long-lasting and reliable support for plants, creating a visually appealing and functional landscape design.

- Q: How is steel wire mesh used in the energy industry?

- Steel wire mesh is commonly used in the energy industry for various applications. It is used in power plants to reinforce concrete structures, such as cooling towers and chimneys, providing strength and durability. Additionally, steel wire mesh is used for filtration purposes in oil and gas operations, helping to separate impurities and ensure the purity of the extracted energy sources. Furthermore, it finds application in electrical transmission and distribution systems, where it serves as a protective barrier around cables and wires, preventing damages and ensuring uninterrupted power supply. Overall, steel wire mesh plays a vital role in enhancing safety, efficiency, and reliability within the energy industry.

- Q: How is steel wire mesh used in reinforcement of environmental projects?

- Steel wire mesh is commonly used in the reinforcement of environmental projects due to its strength and durability. It is used to provide structural support and stability to various eco-friendly initiatives such as retaining walls, slope stabilization, erosion control, and reinforced soil structures. The mesh acts as a reinforcement layer, preventing the movement and displacement of soil or other materials, thus helping to maintain the integrity and longevity of the environmental project.

- Q: What is the maximum temperature that steel wire mesh can withstand?

- The maximum temperature that steel wire mesh can withstand depends on various factors such as the specific type of steel used, the thickness of the wire, and the intended application. Generally, steel wire mesh can withstand temperatures ranging from 500 to 1000 degrees Celsius (932 to 1832 degrees Fahrenheit). However, it is important to consult the manufacturer's specifications or conduct specific tests to determine the exact temperature limit for a particular steel wire mesh product.

- Q: What are the benefits of using steel wire mesh in the automotive refurbishing industry?

- Steel wire mesh offers several benefits in the automotive refurbishing industry. Firstly, it provides exceptional strength and durability, making it ideal for applications that require resistance to heavy impacts and wear. Secondly, the mesh acts as a protective barrier, preventing debris and contaminants from damaging the refurbished parts during the painting and finishing processes. Additionally, the open design of the mesh allows for proper ventilation and airflow, ensuring efficient drying and curing of the painted components. Lastly, steel wire mesh is highly versatile and can be easily shaped and molded to fit various automotive parts, making it a cost-effective and reliable option for the industry.

- Q: How is steel wire mesh used in industrial settings?

- Steel wire mesh is extensively used in various industrial settings for a wide range of applications. One of the primary uses of steel wire mesh is in filtration processes. It is commonly employed as a filter medium to separate particles and contaminants from liquids and gases. The mesh acts as a barrier, allowing the fluid to pass through while trapping unwanted debris, thus ensuring a cleaner and purer end product. Another significant application of steel wire mesh is in reinforcement and construction. It is widely used to reinforce concrete structures, such as roads, bridges, and buildings. The mesh provides additional strength and structural integrity to the concrete, preventing cracks and enhancing its durability. Additionally, it helps distribute the load evenly, reducing the risk of structural failure. Steel wire mesh is also utilized for security purposes in industrial settings. It is commonly used to create fencing and enclosures to restrict access to specific areas, ensuring the safety and protection of personnel and assets. The mesh's strength and rigidity make it an effective barrier against unauthorized entry, vandalism, and theft. In industrial manufacturing processes, steel wire mesh finds applications in material handling, sorting, and sieving operations. It is often employed as conveyor belts or screens to transport or separate materials based on their size, shape, or composition. The mesh can withstand heavy loads, high temperatures, and harsh environments, making it suitable for various industries, including mining, food processing, and recycling. Furthermore, steel wire mesh is used in industrial settings for ventilation and heat dissipation. It is commonly utilized as ventilation panels or screens to allow the free flow of air while preventing the entry of unwanted objects. This helps maintain optimal air quality, temperature, and humidity levels within industrial spaces, promoting a healthier and more comfortable working environment. Overall, steel wire mesh plays a crucial role in industrial settings due to its versatility, strength, and durability. Its applications range from filtration and reinforcement to security, material handling, and ventilation. As a result, it is an indispensable component in numerous industries, contributing to improved efficiency, safety, and productivity.

- Q: Can steel wire mesh be used for food processing?

- Yes, steel wire mesh can be used for food processing. It is commonly used in various applications such as straining, sifting, and filtering in the food industry. The mesh is designed to be hygienic, easy to clean, and resistant to corrosion, making it suitable for food processing environments.

- Q: What are the different edge finishing options available for steel wire mesh?

- There are several edge finishing options available for steel wire mesh, depending on the specific requirements and applications. These options include: 1. Selvage Edge: This is the most common and cost-effective edge finishing option. It involves the wire ends being twisted together to form a loop or hook, which helps to prevent unraveling and provides additional strength to the mesh. 2. Welded Edge: In this finishing method, the wire ends are welded together using heat and pressure. This creates a strong and durable edge that prevents fraying and unraveling. Welded edges are commonly used in industrial applications where high strength and stability are required. 3. Serged Edge: This edge finishing option involves wrapping the wire ends with a separate wire or thread, which is stitched along the edge of the mesh. Serged edges provide added reinforcement and can help to prevent the mesh from unraveling or becoming damaged. 4. Folded Edge: This method involves folding the wire ends back onto the mesh itself, creating a clean and smooth edge. Folded edges are commonly used in applications where aesthetics and a neat appearance are important. 5. PVC Coating: Some steel wire meshes can be coated with PVC (Polyvinyl Chloride) to provide a protective and decorative edge finish. The PVC coating not only enhances the appearance of the mesh but also helps to prevent corrosion and rusting. 6. Hemmed Edge: This finishing option involves folding the wire ends back onto themselves and then stitching or hemming them together. Hemmed edges provide added strength and prevent the mesh from fraying or unraveling. It is important to consider the specific requirements of the application, such as strength, durability, aesthetics, and budget, when selecting the appropriate edge finishing option for steel wire mesh.

- Q: How is steel wire mesh used in erosion control?

- Erosion control commonly employs steel wire mesh to stabilize soil and prevent erosion in different scenarios. The mesh is typically constructed from high-quality steel wires that are woven or welded together, resulting in a resilient and adaptable mesh structure. One key usage of steel wire mesh in erosion control involves slope stabilization. In areas where slopes are prone to erosion, the mesh can be installed to reinforce the soil and hinder its washout. Acting as a barrier, the mesh holds the soil in place and facilitates vegetation growth, which further stabilizes the slope. This is especially crucial in regions with steep slopes or frequent heavy rainfall or water runoff. Aside from slope stabilization, steel wire mesh is also utilized in erosion control for retaining walls and embankments. These structures often bear significant pressure from soil and water, which can cause erosion and instability. By incorporating steel wire mesh onto the surface of the wall or embankment, additional strength and stability are provided, effectively preventing erosion and preserving the structure's integrity. Another application of steel wire mesh in erosion control pertains to sediment control. In areas where sediment runoff poses a concern, such as construction sites or mining operations, the mesh can be employed to establish sediment barriers or retention ponds. Acting as a filter, the mesh permits water to pass through while capturing sediment particles, thereby preventing their displacement by runoff and consequent erosion elsewhere. Moreover, steel wire mesh is commonly employed in erosion control for channel lining. Whether natural or human-made, channels can benefit from the installation of mesh along the banks and bed to prevent erosion and maintain the channel's shape. The mesh provides supplementary reinforcement, mitigating the impact of water flow and averting widening or deepening of the channel. Overall, steel wire mesh serves as a versatile and efficient tool in erosion control. Its strength, flexibility, and durability render it suitable for diverse applications, encompassing slope stabilization, retaining walls, sediment control, and channel lining. Through the utilization of steel wire mesh, erosion can be minimized, soil can be stabilized, and the integrity of structures can be preserved, thereby ensuring long-term erosion control and environmental protection.

Send your message to us

High Quality Stainless Steel Wire Panel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords