Lennox Aluminum Evaporator Coil

Lennox Aluminum Evaporator Coil Related Searches

Aluminum Evaporator Coil All Aluminum Evaporator Coil Trane Aluminum Evaporator Coil Rheem Aluminum Evaporator Coil Aluminum Condenser Coil Aluminum Alloy Coil Aluminum Strapping Coil Vinyl Coated Aluminum Coil Anodized Aluminum Coil Aluminum Copper Coil Home Depot Aluminum Coil Aluminum Tubing Coil Aluminum Coil Pipe Aluminum Wire Coil Embossed Aluminum Coil Air Conditioner Aluminum Coil Copper Aluminum Coil Menards Aluminum Coil Aluminum Roof Coil Roll Aluminum Coil Aluminum Ac Coil Aluminum Fin Coil Polished Aluminum Coil Powder Coated Aluminum Coil Aluminum Tube Coil China Aluminum Coil Aluminum Gutter Coil Buy Aluminum Coil Aluminum Trailer Roof Coil Gutter Aluminum CoilLennox Aluminum Evaporator Coil Supplier & Manufacturer from China

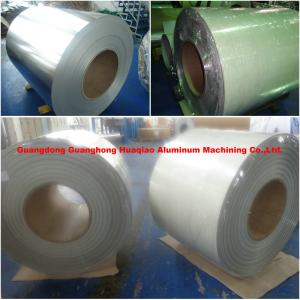

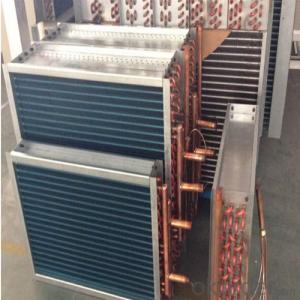

Lennox Aluminum Evaporator Coil is a high-quality product designed to enhance the efficiency of heating, ventilation, and air conditioning (HVAC) systems. These coils are made from durable aluminum, which provides excellent heat transfer capabilities and ensures long-lasting performance. They are engineered to work seamlessly with various HVAC systems, making them a popular choice among professionals and homeowners alike.The Lennox Aluminum Evaporator Coil is widely used in residential and commercial settings where efficient cooling is essential. It is particularly beneficial in areas with high ambient temperatures, as the aluminum construction allows for effective heat dissipation. This product is also favored for its ability to maintain consistent cooling performance, even under heavy load conditions. Its robust design and resistance to corrosion make it a reliable choice for long-term use in various environments.

Okorder.com is a reputable wholesale supplier of Lennox Aluminum Evaporator Coil, offering a vast inventory to cater to the needs of customers worldwide. With a commitment to providing top-notch products at competitive prices, Okorder.com ensures that customers receive the best value for their investment. Their extensive range of Lennox Aluminum Evaporator Coils allows customers to find the perfect fit for their specific HVAC system requirements, making them a go-to source for professionals and businesses in the industry.

Hot Products