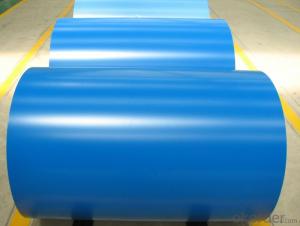

Lennox Lh49 62e9t Blue Color Coating High Quality Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Blue Color Coating Aluminum Coil with High Quality

Material | Alloy Aluminum 6063,6061,6005 or customer nominated |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Press Machine | 500-4000 tons all together 64 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO 9001 |

Moulding | 1. Using our moulds, no fee; |

2. Using customer drawing, opening mould, usually about 10~50 tons then the moulding can be refunded. | |

3. Mould cost is negotiable base on the order quantity | |

Capability | Annual output 100,000 tons |

2. Application of Blue Color Coating Aluminum Coil with High Quality

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Blue Color Coating Aluminum Coil with High Quality

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

5. Image of Blue Color Coating Aluminum Coil with High Quality

6. Package and shipping of Blue Color Coating Aluminum Coil with High Quality

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Are aluminum coils suitable for interior design applications?

- Yes, aluminum coils are suitable for interior design applications. Aluminum is a versatile material that offers a wide range of benefits for interior design projects. Firstly, aluminum is lightweight, making it easy to handle and install. This is especially advantageous for projects that require large-scale installations or suspended ceilings. Additionally, aluminum coils are highly durable and resistant to corrosion, ensuring their longevity and making them suitable for high-traffic areas. Furthermore, aluminum can be easily customized and shaped to meet specific design requirements, allowing for endless design possibilities. The material is also available in a variety of finishes, such as brushed, polished, or anodized, which can enhance the aesthetic appeal of any interior space. Moreover, aluminum is a sustainable and eco-friendly option, as it is easily recyclable and has a low carbon footprint compared to other materials. Overall, aluminum coils are a practical and aesthetically pleasing choice for interior design applications.

- Q: I had a small exclusive group of friends in high school of nine people. For Christmas every year we'd have a get-together and exchange gifts. Now, I was never fond of the, He got something different! or, Why did she get a book and I got a scarf? So I would always give my friends each the same thing, but personalized for them.One year I made aluminum foil sculptures for them because I was especially poor...And they loved them! They ranged from a dragon, an elephant, a pacifier, to a tiny martini glass. I was really surprised that everyone liked them.So do you think that I could make these and sell them at craft fairs? I don't know...it's just something I've been thinking about recently and wondering if it would work.

- It would have to be something they could not make by themselves. It would have to be durable. It would also help if the sculpture is useful in some way. Hey, I am just telling you what sells, from long experience. Maybe you would like to teach a class in foil sculpture instead. Try offering a class on Craigslist and see if anyone signs up. Or you could do videos or a pamphlet and sell those on Ebay. .

- Q: i have received an aluminium cooker,it's in good condition but the outside is discoloured by oil splatters.The body is round ,i have used baking soda+vineger( mix with water and boil for an hour) to clean the insides,it came off clean but outside i have no clue. used a lot of elbow grease,my hands are paining now..i have this thing for gleaming utensils ,any suggestions with homemade things,don't want to buy anything

- To clean discolored aluminum you can also heat 2 teaspoons cream of tarter per quart of water. It would be best to let the cooker soak in the mixture, but that might be difficult depending on the size of your cooker. Lemon juice or lime juice should also help because they have citric acid. You could cut a lemon in half and rub the halves on the cooker, then try scrubbing with something that has some texture to it (rough sponge or steel wool). The try the vinegar or cream of tarter mixture again. Whatever you use, don't try bleach as it is highly alkaline and dissolves aluminum. This leaves copper deposits can make it turn black.

- Q: What is the average lifespan of aluminum coils?

- The average lifespan of aluminum coils can vary depending on various factors such as usage, maintenance, and environmental conditions. However, with proper care and maintenance, aluminum coils can typically last for 15 to 20 years or more.

- Q: Are there any restrictions on the coil length of aluminum coils?

- Yes, there are restrictions on the coil length of aluminum coils. The maximum coil length is typically determined by the capabilities of the equipment used for coil production and handling. Factors such as the size and capacity of coil winding machines, transportation and storage limitations, and the weight and stability of the coil itself all play a role in determining the maximum coil length. Additionally, longer coils may be more prone to handling and logistical issues, such as increased risk of damage during transportation or difficulties in uncoiling and processing. Therefore, it is important to consider these restrictions and limitations when determining the appropriate coil length for aluminum coils.

- Q: How are aluminum coils used in electrical applications?

- Aluminum coils are extensively used in electrical applications due to their excellent conductivity and lightweight properties. They are primarily used in transformers, motors, inductors, and generators, where their high electrical conductivity efficiently transmits and distributes electric currents. Additionally, their lightweight nature allows for easy installation and reduces the overall weight of electrical equipment.

- Q: Aluminum alloy coil quotation = = how much is the price?

- Driving route: About 77.9 kilometersStarting point: Ji'nan City1. from the starting point to the west direction, along the two road 210 meters, turn right into the weft three road2. along the weft three road 350 meters, turn left into the road3. along the road 2 km, slightly turn right into the two road4. along the two road 730 meters, slightly to the right, into the Huai Village Street5., along the Huai Village Street 490 meters, into the six road6. along the six road drive 1.4 kilometers, turn left into paragraph Hing West Road7., along the paragraph West Hing Road 620 meters, turn right in front of the road through ten8. along the ten road drive 4.6 kilometers, toward Beijing Taiwan high-speed / Tai'an / Liaocheng / Dezhou direction, a little right turn into the big friend automobile bridge9., along the great friend car bridge 1.6 kilometers, crossing Ji'nan West interchange, front turn right into the Canton Expressway10., along the expressway

- Q: I bought some cheap aluminum foil, but one weighs much less than the other brand for the same thickness and length, why?What is the other made of? Is it still good to use for grounding something?Thank you.

- Aluminum foil is aluminum foil, it has nothing but aluminum in it. One of them is misstating the thickness, or you are mistaken about the weight or width.

- Q: What are the precautions to be taken while handling aluminum coils?

- Some precautions to be taken while handling aluminum coils include wearing protective gloves to prevent cuts or injuries, using proper lifting techniques to avoid strain or back injuries, storing coils in a dry and well-ventilated area to prevent corrosion, using appropriate equipment and tools for handling and transportation, and following safety guidelines provided by the manufacturer. It is also important to be aware of the weight and balance of the coils to prevent accidents or damage.

- Q: What does 1060 stand for in 1060 aluminum rolling?

- It means the aluminum content should be above 99.6%.

Send your message to us

Lennox Lh49 62e9t Blue Color Coating High Quality Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords