High Quality Aluminum Coil Material for Refrigerator Condenser Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

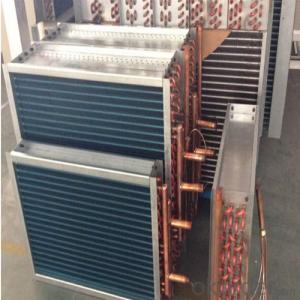

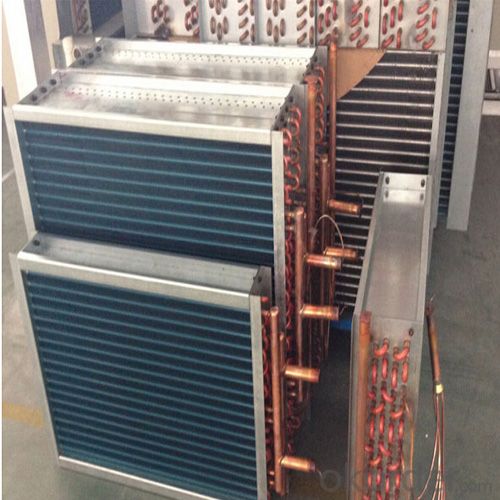

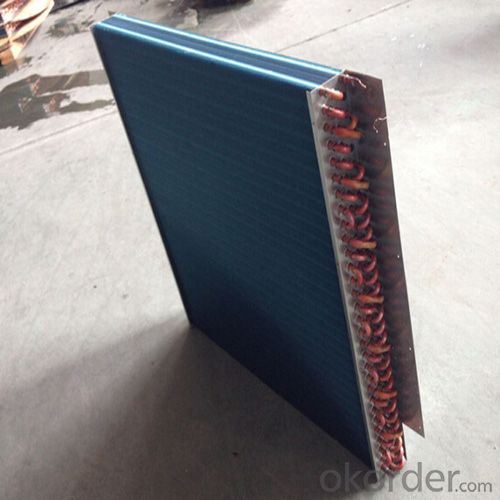

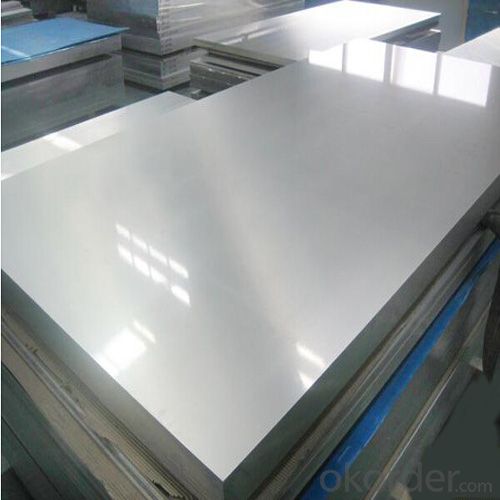

1.Structure of Aluminum Refrigerator Condenser Sheets Description:

Aluminum Refrigerator Condenser Sheets Can be used in a variety of heat exchange constructions where the basic function is to efficiently transfer heat. Also this fin foil can be used for evaporator and condenser in most residential, automotive, and commercial air conditioning units. In addition, this foils are used in humidifiers, dehumidifiers, baseboard space heaters of various types, and other equipment.

2.Main Features of Aluminum Refrigerator Condenser Sheets:

Alloy: 8011, 1100, 1200, 1030B, 3102, 3003

Temper: O, H22, H24, H26

Thickness: 0.08-0.3mm

Core ID: 76mm, 150mm, 200mm, 300mm, etc.

Width: Variety

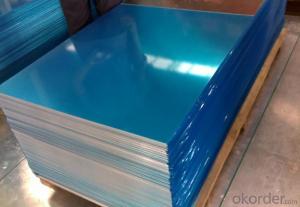

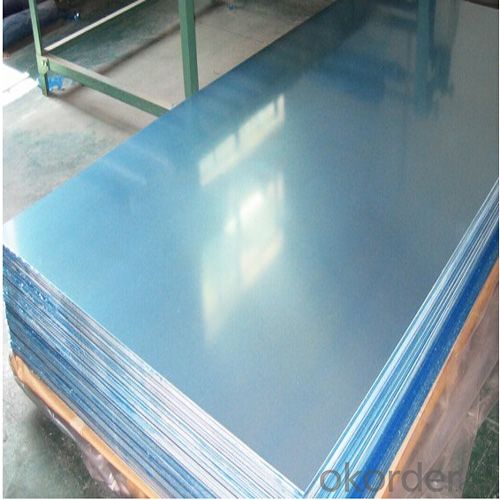

3. Aluminum Refrigerator Condenser Sheets Images:

4. Aluminum Refrigerator Condenser Sheets Specification:

Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Al |

1060 | 0.25 | 0.4 | 0.05 | 0.05 | 0.05 | 0.05 | 0.03 | 99.6 | ||

1050 | 0.25 | 0.4 | 0.05 | 0.05 | 0.05 | 0.05 | 0.03 | 99.5 | ||

1100 | 0.95 | 0.05-0.2 | 0.05 | 0.1 | 99.0 | |||||

1200 | 1.0 | 0.05 | 0.05 | 0.1 | 0.05 | 99.0 | ||||

3003 | 0.6 | 0.7 | 0.05-0.2 | 1.0-1.5 | 0.1 | remainder | ||||

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: What are the potential applications of coil-brushed aluminum coils?

- Due to its unique properties, coil-brushed aluminum coils have a wide range of potential applications. Here are several examples: 1. Architectural projects can benefit from the use of coil-brushed aluminum coils. These coils can be utilized for building facades, roofing, cladding, and decorative elements, adding a sophisticated and modern look to structures. 2. In the field of interior design, coil-brushed aluminum coils can be used for wall paneling, ceiling tiles, partition screens, and decorative accents. The brushed texture provides a sleek and stylish appearance, making them suitable for residential, commercial, and hospitality settings. 3. Coil-brushed aluminum coils can be incorporated into furniture designs, including tables, chairs, shelves, and cabinets. The brushed finish adds a contemporary touch to the furniture pieces, making them suitable for modern and minimalist styles. 4. The lightweight and corrosion-resistant nature of aluminum make it an ideal material for automotive applications. Coil-brushed aluminum can be used in the manufacturing of interior trim, dashboards, door panels, and other decorative components in cars, trucks, and motorcycles. 5. The excellent conductivity and heat dissipation properties of coil-brushed aluminum make it suitable for the production of electronic devices such as smartphones, laptops, and tablets. The brushed finish adds a premium feel to these products. 6. Coil-brushed aluminum coils are also useful in the manufacturing of signage and branding elements. The brushed texture enhances the visibility and aesthetics of the signs, making them stand out and convey a sense of quality and professionalism. 7. In the kitchenware and appliances industry, coil-brushed aluminum is a popular choice due to its durability, heat resistance, and easy cleaning properties. It can be used to produce cookware, bakeware, kitchen utensils, and appliance panels, providing a sleek and modern look. 8. Coil-brushed aluminum coils are also utilized in the production of packaging and labeling materials. The brushed finish adds an elegant touch to product packaging, making it visually appealing and attractive to consumers. In conclusion, coil-brushed aluminum coils have a wide range of potential applications in various industries, including architecture, interior design, automotive, electronics, kitchenware, signage, and packaging. Their unique properties make them versatile and desirable for different projects.

- Q: What are the proper storage methods to maintain the quality of aluminum coil for future use?

- <p>To store aluminum coil for future use, ensure it is kept in a cool, dry place away from direct sunlight and moisture. Stack the coils on flat, level surfaces with appropriate padding to prevent damage. Avoid stacking with other metals to prevent galvanic corrosion. Use clean, dry hands or gloves when handling to prevent oil and dirt from contaminating the surface. Store in a controlled environment with a relative humidity below 65% and a temperature between 32掳F to 90掳F (0掳C to 32掳C). Regularly inspect the coils for any signs of corrosion or damage.</p>

- Q: This question asks for methods to determine the age of an aluminum coil, distinguishing between new and old.

- <p>To determine if an aluminum coil is new or old, you can look for several indicators: the surface condition, such as scratches or signs of wear; the quality of the protective coating, if any, which may degrade over time; the manufacturing date or batch number, if available; and the overall appearance and shine. New coils typically have a smooth, shiny surface with no significant scratches or dents, and a consistent protective coating. Old coils may show signs of oxidation, discoloration, or other forms of degradation. Additionally, testing the coil's physical properties, such as tensile strength, can provide clues about its age, as these properties can degrade over time.</p>

- Q: How are aluminum coils used in the production of aircraft components?

- Aluminum coils play a vital role in the manufacturing of aircraft components, offering a combination of strength, durability, and lightness that makes them ideal for this purpose. One primary application of aluminum coils in aircraft production involves fabricating sheet metal parts. Through techniques like rolling, stretching, and bending, these coils are transformed into flat sheets of aluminum, which are then cut and shaped to create wings, fuselage panels, and tail surfaces. The lightweight nature of aluminum makes it a preferred material for aircraft construction, as it reduces the overall weight of the aircraft and improves fuel efficiency and performance. Using aluminum coils allows manufacturers to easily produce thin and lightweight parts, contributing to the overall weight reduction of the aircraft. Additionally, aluminum coils are utilized in the production of structural components such as frames and beams. These coils are formed into extrusions, which are then cut and joined to create the structural elements of the aircraft. Aluminum's high strength-to-weight ratio makes it an excellent choice for these components, providing the necessary strength while keeping the aircraft's weight low. Apart from its structural applications, aluminum coils are also used in the production of various aircraft systems. For example, they are incorporated into the construction of heat exchangers, air conditioning units, and fuel tanks. Aluminum's excellent thermal conductivity allows for efficient heat transfer, which is essential for maintaining optimal operating conditions within the aircraft. Overall, aluminum coils are extensively utilized in the manufacture of aircraft components due to their lightweight nature, high strength, and excellent thermal properties. Their versatility and the ability to be processed into different shapes and sizes make them the preferred material for manufacturing critical aircraft parts, ensuring the safety, performance, and efficiency of modern aircraft.

- Q: Can aluminum coils be used in telecommunications infrastructure?

- Yes, aluminum coils can be used in telecommunications infrastructure. Aluminum is commonly used in various components of telecommunications infrastructure, including cables, connectors, and antennas. It is preferred for its lightweight, durable, and corrosion-resistant properties, making it suitable for outdoor installations. Additionally, aluminum coils provide excellent conductivity, ensuring efficient transmission of signals in telecommunications systems.

- Q: Is it safe and appropriate to use aluminum coils for food packaging?

- <p>Yes, aluminum coils can be used for food packaging. Aluminum is a common material in the food packaging industry due to its lightweight, durability, and excellent barrier properties against light, oxygen, and moisture. It is widely used in the production of flexible packaging, such as pouches, laminates, and foils. However, it's important to ensure that the aluminum coils meet food-grade standards and are used in accordance with food safety regulations to prevent any contamination or health risks.</p>

- Q: How are aluminum coils measured and specified?

- Aluminum coils are measured and specified based on several key factors. The first aspect is the thickness of the coil, which is typically measured in gauge or millimeters. The thickness determines the strength and durability of the coil, with thicker coils being more robust. Another important specification is the width of the coil, which is usually measured in inches or millimeters. The width determines the size and coverage area of the coil, with wider coils offering greater coverage. The length of the coil is also a crucial specification. It is typically measured in feet or meters and determines the amount of material available for a specific project. Longer coils are often preferred as they minimize the number of joints required during installation. Additionally, the alloy and temper of the aluminum used in the coil are specified. Different alloys have varying mechanical and chemical properties, making them suitable for different applications. The temper refers to the heat treatment process applied to the aluminum, affecting its hardness and flexibility. Coil weight is another important consideration. It is typically measured in pounds or kilograms and determines the handling and transportation requirements for the coil. Lastly, the surface finish of the coil is specified. Common finishes include mill finish, which is untreated, and coated finishes such as painted or anodized. The surface finish affects the appearance and corrosion resistance of the coil. Overall, the measurement and specification of aluminum coils involve factors like thickness, width, length, alloy, temper, weight, and surface finish. These specifications help ensure that the coils meet the desired requirements for various applications.

- Q: I was wandering, if your spear's shaft is made of aluminum, does that have any strength to it, i mean, say you had to block with the shaft, would a weapon break through like your basic sword or basic axe, i don't mean big heavy swords and axes, but like average ones, could it break through an aluminum shaft of a spear?

- Why an aluminum spear? Why not a wood spear? A spear needs to be able to take the shock of hard contact against other weapons. If you are thinking that aluminum is lighter therefore faster, then you make a widely held mistake. If tow people of equal skill with a weapon were to face each other, then the one that has greater speed would have some advantage........but that does not mean that he would be the winner. There are many other factors that can determine the outcome. Better timing for one can beat speed. The martial arts are not simple things that can be calculated like math. Besides skills there is luck. None of us can predict that. Put two people against each other... One with an aluminum spear, the other with a wood spear, but better skills, and I'll bet on the better trained person. but as I stated, anything can happen due to luck, a mistake (it take only one), conditions. If two people fight and one wins, does that mean that he would always win if they fight over and over? These questions always assume way to many things to be true. Therefore they are flawed questions from the start. ... ...

- Q: Can aluminum foil coil be stores for a long time?

- It is ok within one or two years, but for five or six years, it will be oxidized.

- Q: Can aluminum coils be used in roofing or cladding systems?

- Yes, aluminum coils can be used in roofing or cladding systems. Aluminum is a lightweight and corrosion-resistant material, making it suitable for these applications. It offers durability, flexibility, and ease of installation, making it a popular choice in the construction industry.

Send your message to us

High Quality Aluminum Coil Material for Refrigerator Condenser Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords