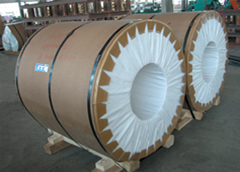

Smooth Surface Embossed Aluminum Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Alloy: AA 5052

Temper:H14/16/18/22/24/32,HO etc.

Thickness:0.2mm—100mm

Width:100mm—2300mm (Can be slitted)

InnerDiameter: 508MM

CoilWeight:500kg-3000kg(Max.)

Application: Foil stock, Circles, Roofing, Canstock, Marine plate,Anti-sliperypurpose in vehicles, packing and appliance.

- Q: Is it appropriate to use a wire brush for cleaning an aluminum coil?

- <p>Using a wire brush to clean an aluminum coil is not recommended. Wire brushes can cause scratches and damage the surface of the aluminum, which can lead to corrosion over time. Instead, use a soft cloth or sponge with a mild cleaning solution to gently clean the coil. This will prevent any damage to the aluminum while effectively removing dirt and debris.</p>

- Q: We had a BBQ a few days ago and left our pack of aluminum foil on the table out side. It rained that night and the following night. I went out to take the trash out and heard a odd noise. It was the pack of foil boiling hot. The water from the rain was steaming out of it. When I picked it up you could feel the warmth coming from the center of it.It was 2 days after the BBQ, was never near the heat of that. It was on a separate table.The table is shaded all day, so it didn't heat from the sun. Plus aluminum does not transfer heat.It just don't make since to me. I unrolled some of it and it is dark grey from being heated so hot. I never heard of it and tried to find info, but to no avail. So out of curiosity I am asking.

- Aluminum does not go wel in heat, in fact if left under extreme heat + pressure (A.K.A.) microwave, or toast oven, it will explode, there will be nothing left but tiny fragments of aluminum tinfoil.

- Q: How do aluminum coils perform under high-temperature applications?

- Aluminum coils are renowned for their exceptional resistance to heat and their ability to perform well in applications that involve high temperatures. With a melting point of approximately 660 degrees Celsius (1220 degrees Fahrenheit), aluminum coils can endure and function efficiently even when exposed to elevated temperatures. The high thermal conductivity of aluminum allows for the rapid transfer of heat away from the coil, preventing overheating and potential damage. This characteristic enables aluminum coils to effectively dissipate heat, resulting in improved thermal management and enhanced performance in environments with high temperatures. In addition, aluminum coils possess good corrosion resistance, which is crucial in situations where heat and moisture are present. The naturally occurring oxide layer on the surface of aluminum acts as a protective barrier against corrosion, ensuring the durability and reliability of the coil, even in challenging conditions. Furthermore, aluminum coils are lightweight and highly malleable, making them easy to install and integrate into a variety of systems and applications. This versatility renders them suitable for a wide range of high-temperature applications, including heat exchangers, automotive components, HVAC systems, and electrical devices. However, it is important to note that subjecting aluminum to extreme temperatures beyond its melting point can cause the material to weaken or deform. Therefore, it is essential to carefully consider the specific temperature requirements and limitations of the aluminum coil before implementing it in a high-temperature application.

- Q: show step by step

- First write out the formula reaction: 4Al + 3O2 --- 2Al2O3 Next, find the number of moles of oxygen gas needed to oxidize 3.42 g of aluminium completely. From the cchemical equation above, 3 mol of oxygen is used to oxidize completely 4 mol of aluminium. Calculate the no. of moles of aluminium used: no. of moles of aluminium used = 3.42 g / molar mass of Al = 3.42 g / 26.98 g mol^-1 = 0.127 mol Use the mole ratio concept to find the no. of moles of oxygen required: no. of moles of oxygen required : no. of moles of aluminium used = 3 : 4 no. of moles of oxygen required / 0.127 = 3 / 4 no. of moles of oxygen required = (3 / 4)(0.127) = 0.095 mol Next, use the gas equation PV = nRT [P: Pressure of gas in Pa; V: Volume of gas in m^3; n: no. of moles; R, gas constant, 8.314 J mol^-1 K^-1; T, Temperature of gas in K] -Convert 0.975 atm to Pa: 0.975 atm = (0.975 x 101325) Pa = 98791.875 Pa -Convert 25 oC to K: 25 oC = (25 + 273) K = 298 K -Substitute into the equation PV = nRT and solve it: (98791.875)(V) = (0.095)(8.31)(298) (98791.875)(V) = 235.2561 V = 235.2561 / 98791.875 = 0.002381 m^3 = (0.002381 x 10^3) L = 2.381 L

- Q: What specific conditions or precautions are necessary to ensure the proper storage of aluminum coils to maintain their quality and prevent damage?

- <p>Yes, there are special requirements for storing aluminum coils to ensure their quality and prevent damage. Aluminum coils should be stored in a cool, dry place away from direct sunlight and moisture. They should be kept on flat, level surfaces with proper support to prevent warping or denting. It's also important to avoid stacking them too high to prevent crushing. Additionally, coils should be protected from contact with corrosive materials or chemicals that could cause oxidation or staining. Proper labeling and tracking of coils is also essential for inventory management.</p>

- Q: I was going to buy a turkey roaster pan today and an elderly couple stopped me and told me to buy another one that was made of stainless steel instead of aluminum because aluminum does something to your brain. What is the story?Just curious. Does this also ring true for using a sheet of aluminum foil over baking sheets while cooking cookies or fries or something? I always coat my cookie sheets with foil. Just curious...

- For okorder /19

- Q: Can aluminum coils be customized to specific thicknesses and widths?

- Yes, aluminum coils can be customized to specific thicknesses and widths.

- Q: Are aluminum coils suitable for interior design applications?

- Yes, aluminum coils are suitable for interior design applications. Aluminum is a versatile material that offers a wide range of benefits for interior design projects. Firstly, aluminum is lightweight, making it easy to handle and install. This is especially advantageous for projects that require large-scale installations or suspended ceilings. Additionally, aluminum coils are highly durable and resistant to corrosion, ensuring their longevity and making them suitable for high-traffic areas. Furthermore, aluminum can be easily customized and shaped to meet specific design requirements, allowing for endless design possibilities. The material is also available in a variety of finishes, such as brushed, polished, or anodized, which can enhance the aesthetic appeal of any interior space. Moreover, aluminum is a sustainable and eco-friendly option, as it is easily recyclable and has a low carbon footprint compared to other materials. Overall, aluminum coils are a practical and aesthetically pleasing choice for interior design applications.

- Q: Are aluminum coils suitable for food storage containers?

- Yes, aluminum coils are suitable for food storage containers. Aluminum is a non-toxic and non-reactive metal that is safe for storing food. It is lightweight, durable, and has excellent temperature retention properties, making it a popular choice for food storage containers.

- Q: Are there any safety concerns when handling aluminum coils?

- Yes, there are some safety concerns when handling aluminum coils. One of the main concerns is the risk of injury from sharp edges. Aluminum coils are typically formed into long, thin sheets that can have sharp edges. It is important to handle them with care and wear appropriate protective gloves to avoid cuts and abrasions. Another safety concern is the potential for injury due to the weight of the coils. Aluminum coils can be quite heavy, especially when they are stacked together. It is important to use proper lifting techniques and equipment to prevent strains and back injuries. Additionally, there is a potential risk of fire when handling aluminum coils. Aluminum is a highly flammable material and can ignite if exposed to sparks, open flames, or high temperatures. It is crucial to store and handle aluminum coils away from any potential ignition sources and ensure that the area is well-ventilated to prevent the buildup of flammable vapors. Finally, it is important to be aware of the potential health risks associated with aluminum. While aluminum itself is not considered highly toxic, there is some evidence to suggest that prolonged exposure to high levels of aluminum can be harmful to human health. Therefore, it is important to take appropriate precautions, such as wearing respiratory protection when working with aluminum coils in dusty environments and following proper hygiene practices to minimize the risk of exposure. Overall, with proper training, precautions, and adherence to safety guidelines, the risks associated with handling aluminum coils can be minimized.

Send your message to us

Smooth Surface Embossed Aluminum Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords