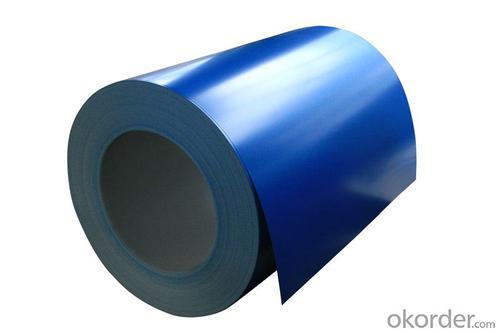

Vinyl Coated Aluminum Coil for HVAC Equipments

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

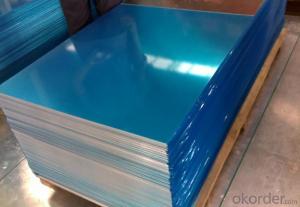

Color Coated Aluminium Roll For HAVC Equipment

Specifications

Grade | 1050,1060,1070, 1100, 1200, 2024,3003, 3004,3005, 3105, 5005,5052 5182,5754,8011 etc |

Thickness | 0.1~1.5mm |

Width | 100~2500mm |

Surface Treatment | PVDF and PE coated |

Temper | O-H112 |

Hardness | More than 2H |

Yield(≥MPa) | 160 |

Ultimate Strength(≥MPa) | 175 |

Elongation(≥%) | 6 |

Packing Material | Moisture-proof agent, steel tape bundle, wooden pallet, brown paper |

Method | Vertical(eye to sky) or horizontal(eye to wall) |

Standard Specification | 1000mm×C, 1200mm×C, etc |

Shipping | Container Loading or Bulk Pack |

Characteristics

1) Excellent weather-proof durability

2) Anti-ultraviolet

3) High erosion resistance

4) Stable color and gloss

5) Good mechanical processing performance

6) Abrasion resistance

7) Anti-impact

8) High flexibility

Application

1) Construction material further processing

2) Solar cell frame, solar battery frame

3) Glass curtain wall frame

4) Interior decoration

5) Elevator decoration

6) Signs, nameplate, bags making.

7) Automobile parts material

8) Office and Household appliances: HVAC equipments

9) The consumer electronics: mobile phones, digital cameras, MP3 .etc.

Coating varieties

Polyester Coatings (PE)

PE (polyester) coatings exhibit an excellent combination of hardness, flexibility, flow, appearance, and superior resistance to dirt retention in indoor and outdoor applications. These coatings are highly resistant to abrasion, metal marking, staining, and marring, and require minimal maintenance. Glazetech uses polyester paints which provide excellent colour and gloss retention properties.

Polyvinylidene Fluoride Coatings (PVDF)

PVDF (polyvinylidene fluoride) is a chemical resistant thick film barrier coating commonly used in architectural applications where both excellent appearance and substrate protection must be maintained over a long period of time. This coating is unaffected by most chemicals and solvents and has excellent wear and abrasion resistance. PVDF also has a high dielectric strength, excellent resistance to weathering and the ability to self extinguish.

- Q: How do aluminum coils contribute to the thermal conductivity of products?

- Aluminum coils play a significant role in enhancing the thermal conductivity of various products. Due to the exceptional thermal properties of aluminum, coils made from this material are highly efficient at transferring heat. The thermal conductivity of aluminum is much higher compared to other common metals, such as steel or copper. This means that when aluminum coils are used in products, they can quickly and effectively transfer heat from one area to another. For instance, in HVAC systems, aluminum coils are often utilized in air conditioning units. When the refrigerant flows through the coils, the aluminum material rapidly absorbs the heat from the surrounding air. This allows for efficient cooling, as the heat is quickly transferred away from the air and expelled, resulting in a more comfortable indoor environment. Similarly, in heat exchangers, aluminum coils facilitate the transfer of heat between two fluids or gases. The high thermal conductivity of the aluminum allows for efficient heat exchange, ensuring that the desired temperature is achieved in a timely manner. Moreover, aluminum coils are lightweight, which makes them more convenient to handle and install in various products. This characteristic is particularly advantageous in industries such as automotive, aerospace, and electronics, where weight reduction is crucial. In summary, aluminum coils significantly contribute to the thermal conductivity of products by efficiently transferring heat due to their high thermal conductivity properties. Their lightweight nature further enhances their versatility and practicality in multiple industries.

- Q: How do aluminum coils compare to other metals in terms of strength?

- Aluminum coils generally have lower strength compared to other metals such as steel or titanium. While aluminum is lightweight and offers good corrosion resistance, it may not possess the same level of strength and durability as some other metals. However, the specific strength of aluminum coils can vary depending on the alloy composition and manufacturing process.

- Q: The box doesn't tell me. I need to know because my gun range won't allow steel or aluminum cartridges

- A magnet will tell if there is steel. Usually the concern is only for steel in the projectile, not the case. Indoor ranges are worried about damage to their back stop. Outdoor ranges may be concerned about starting fires due to sparks. If a range told me the cases could not be steel or aluminum, I would find another range. They probably want to keep the shells you leave on the ground, but don't want to have to separate the reloadable from the non-relaodable. That makes them bums.

- Q: Are there any specific guidelines for the handling of aluminum coils?

- There exist specific guidelines for the handling of aluminum coils, with several key points to consider: 1. Appropriate lifting techniques: To handle aluminum coils, it is crucial to utilize suitable lifting equipment such as cranes or forklifts. These tools must possess the capacity to handle the weight of the coils in order to prevent accidents or damage. 2. Usage of protective gear: Workers must wear personal protective equipment (PPE) like gloves and safety goggles to safeguard themselves against sharp edges or potential injuries during handling. 3. Secure packaging: Aluminum coils must be stored or transported in secure packaging to prevent damage. This can be accomplished by employing suitable pallets, straps, or protective covers to ensure that the coils are held in place and protected against external factors like moisture or impact. 4. Proper stacking: When storing or transporting aluminum coils, it is vital to stack them in a manner that guarantees stability and prevents them from falling or causing accidents. The coils should be stacked evenly and securely, with adequate support and spacing between each stack to avoid deformation or damage. 5. Avoidance of contact with corrosive materials: Aluminum coils should not come into contact with corrosive materials such as acids or alkalis, as they can cause damage or corrosion to the metal. It is important to store aluminum coils in a clean and dry environment to preserve their quality. 6. Gentle handling: Aluminum coils are prone to scratches, dents, and other forms of damage, thus they should be handled with care to avoid these issues. Dragging or sliding the coils during handling should be avoided, and they should be placed gently to prevent any potential damage. 7. Training and supervision: Workers involved in the handling of aluminum coils should receive adequate training and supervision to ensure adherence to the specific guidelines and safety procedures. Regular training sessions can help refresh their knowledge and reinforce safe handling practices. By adhering to these guidelines, the proper handling of aluminum coils can be ensured, thereby reducing the risk of accidents, damage, or loss of quality.

- Q: how many chloride ions are present? how many chlorine ions are present? what is the mass in grams of one formula unit of aluminum chloride?

- Aluminum Chloride is simply AlCl3 So In each mole of AlCl3 there are 1 mol of Al 3 mol of Cl We know (from periodic table), 1 mol of Al weighs 26.98 g 1 mol of Cl weighs 35.47g so 1 mol of AlCl3 weighs 26.98g + 3x35.47g = 133.39 g sooo moles of AlCl3 = 37.2 g /133.39 g/mol = 0.279 mol in one mol of anything, there are 6.02 x 10 ^ 23 of that thing... so we have 0.279 mol x 6.02 x 10 ^ 23 molecules /mole = 1.68 x 10 ^ 23 And, we know one molecule of AlCl3 dissociates into one Al ion and 3 Cl ions sooo 1.68 x 10 ^ 23 AlCl3 ions dissociate into 1.68 x 10 ^ 23 Al ions so answer is 1.68 x 10 ^ 23 Al ions

- Q: What are the common surface repair methods for aluminum coils?

- Common surface repair methods for aluminum coils include sanding, buffing, and polishing. Sanding is used to remove surface imperfections and smooth out any rough areas. Buffing involves using a buffing wheel and compound to restore the shine and luster of the aluminum surface. Polishing is done using a polishing compound or aluminum polish to further enhance the appearance and create a protective barrier against corrosion.

- Q: Is it possible to use an aluminum coil for cooking rice?

- <p>While it is technically possible to use an aluminum coil to cook rice, it is not recommended due to potential health risks. Aluminum can leach into food, especially when heated, and long-term exposure to aluminum may have adverse effects on health. Instead, use materials like stainless steel, cast iron, or non-stick cookware specifically designed for cooking rice to ensure safety and better results.</p>

- Q: How are aluminum coils tested for surface adhesion?

- Aluminum coils are tested for surface adhesion through various methods to ensure the quality and performance of the material. One common method is the tape test, where a piece of adhesive tape is applied firmly to the surface of the coil and then quickly removed. The adhesion is evaluated by assessing the amount of coating or paint that comes off with the tape. If excessive coating is removed, it indicates poor surface adhesion. Another method involves using a cross-cut or knife test, where a grid pattern is cut into the surface of the coil using a sharp blade. The grid is then covered with an adhesive tape and quickly removed. The adhesion is evaluated by examining the amount of coating or paint that is removed from the cut lines. If there is minimal or no coating removal, it indicates good surface adhesion. In addition, the pull-off adhesion test is often conducted using specialized equipment. This test involves attaching a device to the surface of the coil and applying a gradually increasing force until the coating or paint starts to detach. The force required to cause the detachment is measured, and it provides a quantitative measure of the surface adhesion strength. Overall, these testing methods help manufacturers assess the surface adhesion of aluminum coils and ensure that they meet the required standards for various applications, such as in the automotive, aerospace, or construction industries.

- Q: What are the different coil packaging materials used for aluminum coils?

- There are several different coil packaging materials commonly used for aluminum coils. These materials are designed to protect the coils during transportation and storage, ensuring they arrive at their destination in good condition. One of the most popular coil packaging materials for aluminum coils is plastic. Plastic packaging can come in the form of shrink wrap, stretch film, or plastic bands. Shrink wrap is often used to tightly encase the coils, providing a secure and protective covering. Stretch film, on the other hand, is used to tightly wrap the coils together, preventing them from shifting and potentially causing damage. Plastic bands are used to secure the coils together, offering an additional layer of stability. Another commonly used packaging material for aluminum coils is paper. Kraft paper or corrugated cardboard is often used to wrap and protect the coils. This type of packaging provides cushioning and prevents the coils from scratching or rubbing against each other during transit. Paper packaging is also easily recyclable, making it an environmentally friendly option. In addition to plastic and paper, steel strapping is sometimes used to package aluminum coils. Steel strapping offers excellent strength and durability, ensuring that the coils remain securely bundled during transportation. This type of packaging material is particularly useful for heavy-duty applications where extra protection is needed. Overall, the choice of coil packaging material for aluminum coils depends on factors such as the size and weight of the coils, transportation requirements, and the level of protection needed. By using the right packaging materials, aluminum coils can be safeguarded against damage and arrive at their destination in optimal condition.

- Q: Is it possible to utilize recycled aluminum coils for a project instead of purchasing new ones?

- <p>Yes, you can use recycled aluminum coils in your next project instead of buying new ones. Recycled aluminum is environmentally friendly and often more cost-effective. It maintains the same properties as new aluminum, making it suitable for various applications. Ensure the recycled coils meet the quality standards required for your project. Check for any impurities or damage that might affect performance. Using recycled materials not only reduces waste but also conserves resources.</p>

Send your message to us

Vinyl Coated Aluminum Coil for HVAC Equipments

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords