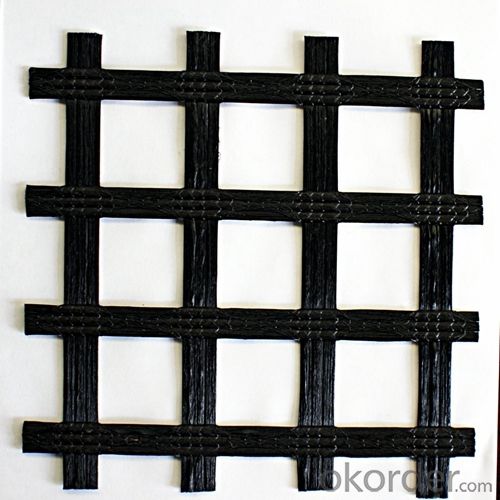

Woven Geogrids for Reinforcement and Separation in Civil Engineering Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

Uni-Axial Geogrids For Slopes

Uniaxial geo grids typically have their tensile strength in the machine (roll) direction. They are mainly used to reinforce the soil mass in a steepened slope or segmental retaining wall. On occasion, they function as a wrapping to confine the aggregate in the wire forms of welded wire faced steepened slopes.

Our niaxial geogrids are made from polyester yarn, knitted or woven into a stable structure and have a PVC or polymeric coating. These flexible, user-friendly geogrids are inert to biological degradation and resistant to creep, strain and naturally found chemicals.

Fiberglass geogrid/glass fiber geogrid with CE certificate

1)fiberglass geogrid with CE certificate

2)Materials:fiberglass

3) Tensile strength:MD/CD:30 ~ 200kn/m

4)WIdth:1 ~ 6m

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Can geogrids be used in landfill applications?

- Yes, geogrids can be used in landfill applications. Geogrids are commonly used in landfill construction to enhance stability, increase load-bearing capacity, and prevent soil erosion. They help to distribute the load more evenly, improve the overall structural integrity, and provide additional support to the landfill liner system.

- Q: What are the criteria for the use of plastic geogrid

- Warp knitted grating, steel plastic grille, plastic grille, fiberglass grille

- Q: Product specifications and performance parameters of glass fiber grating

- Glass fiber geogrid technical parameters classification model breaking strength (KN/m) elongation at break (%) mesh size (mm * mm) width (m) meridional zonal glass fiber geogrid

- Q: Can geogrids be used in reinforcement of embankments over soft soils?

- Yes, geogrids can be used in the reinforcement of embankments over soft soils. Geogrids are commonly used in civil engineering to provide stability and strength to soil structures, including embankments. By distributing the load and reducing lateral movement, geogrids can effectively reinforce embankments over soft soils, preventing slope failure and improving overall stability.

- Q: How many square meters of geogrid?

- A grille is made of polypropylene, PVC polymer and thermoplastic or molded by two-dimensional grid or a certain height of the three-dimensional mesh screen, when used as a civil engineering, called geogrid.

- Q: Geogrid is divided into several?

- Glass fiber grid warp knitted grid one-way geogrid two-way grid steel grating

- Q: Are geogrids suitable for erosion control?

- Yes, geogrids are suitable for erosion control. They are commonly used in various erosion control applications such as slope stabilization, retaining walls, and embankments. Geogrids provide reinforcement to the soil, preventing erosion and maintaining the integrity of the surface.

- Q: How do geogrids enhance the stability of mechanically stabilized earth walls?

- Geogrids enhance the stability of mechanically stabilized earth walls by providing reinforcement and increasing the overall strength of the structure. They are typically made of high-strength materials like polyester or polypropylene, and are placed within the soil layers of the wall. The geogrids interact with the soil, creating a tensile force that redistributes the loads and prevents excessive movement or sliding of the wall. This reinforcement improves the overall stability and durability of the mechanically stabilized earth wall.

- Q: Are geogrids suitable for use in slope reinforcement during excavation?

- Yes, geogrids are suitable for use in slope reinforcement during excavation. Geogrids are commonly used in slope stabilization and reinforcement projects due to their high tensile strength and ability to distribute loads. They can effectively prevent soil erosion and provide stability to slopes during excavation, making them a reliable choice for such applications.

- Q: What are the different types of geogrids?

- There are several different types of geogrids, including biaxial geogrids, uniaxial geogrids, and triaxial geogrids. Biaxial geogrids have strength in two directions and are commonly used for soil stabilization and reinforcement. Uniaxial geogrids have strength in one direction and are often used for retaining walls and steep slopes. Triaxial geogrids have strength in three directions and are primarily used for load-bearing applications such as road construction and pavement reinforcement.

Send your message to us

Woven Geogrids for Reinforcement and Separation in Civil Engineering Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords